Double-cooling radiation test system and method

A technology of a test system and a cooling system, which is applied in a double-cooling irradiation test system and field, can solve the problems of high cost, different calorific value, and low utilization rate of the irradiation circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

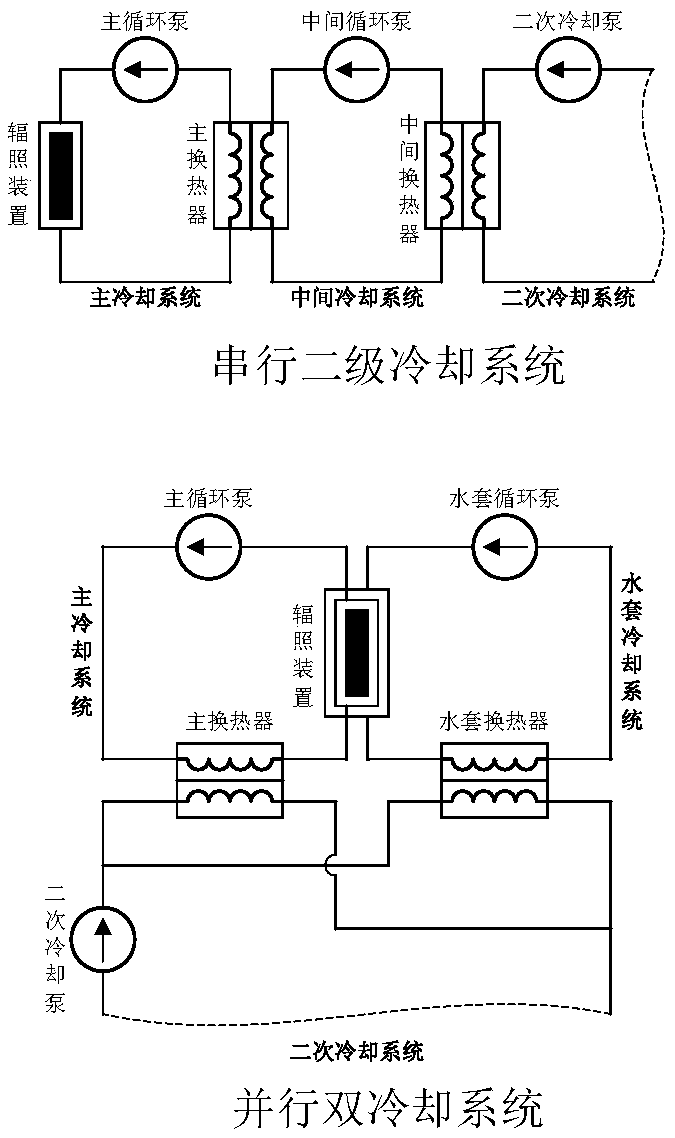

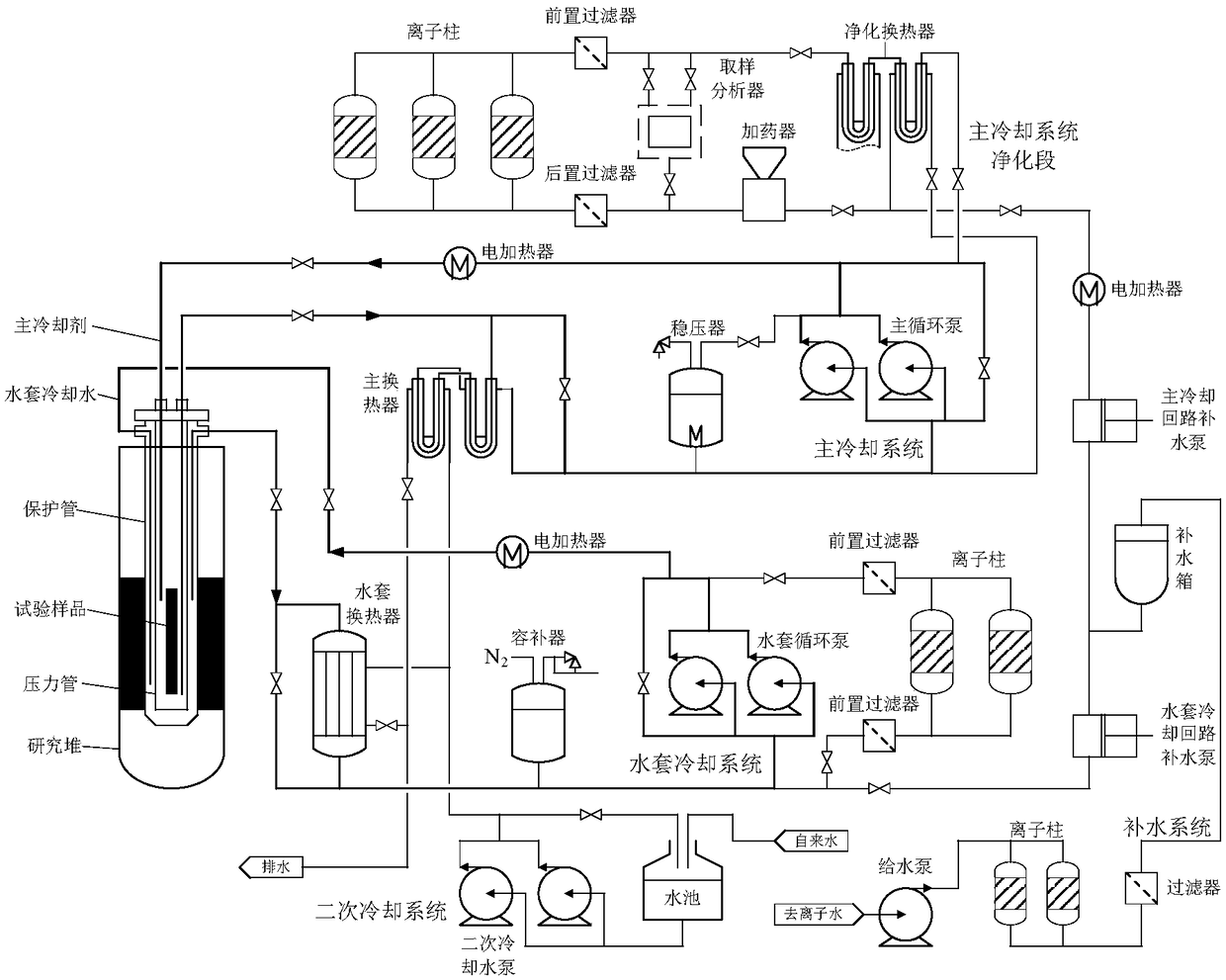

[0033] The double cooling radiation test system of this embodiment 1, combined with the attached figure 1 And attached figure 2 The present invention will be described.

[0034] The difference between the dual cooling radiation test system and the general serial secondary cooling radiation test system is as follows: figure 1 shown. The dual-cooling irradiation test system is composed of a high-temperature and high-pressure main cooling system and a low-temperature and low-pressure water jacket cooling system. Both subsystems are finally cooled by a secondary cooling system. According to different irradiation test / production requirements, the main cooling system and water jacket cooling system of the dual-cooling irradiation test system can be operated independently to achieve different thermal and hydraulic environments and cooling functions. The main cooling part and the water jacket cooling part of the dual-cooling radiation test system can run in parallel simultaneously...

Embodiment 2

[0039] Based on the above-mentioned dual-cooling irradiation test system, the following operating conditions can be realized:

[0040] Working condition 1: The main cooling system runs alone

[0041] The main cooling system is capable of providing fuel elements with a thermal-hydraulic and hydrochemical environment that simulates PWR conditions; it can take out the heat released from the fuel elements and transfer it to the secondary cooling water through the main regenerative heat exchanger, which can facilitate the adjustment of incoming and outgoing radiation The main coolant temperature, pressure, flow and liquid level of the device. The main cooling circuit is connected with the inlet and outlet of the pressure tube of the irradiation device to form a forced circulation high temperature and high pressure closed circuit. The main coolant is driven by one main pump, and the other is standby. After passing through the check valve at the outlet of the main pump, it flows to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com