Photovoltaic module support system

A support system and photovoltaic module technology, applied in the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of high manufacturing cost, low product qualification rate, high cost, etc., shorten the construction progress, improve economic benefits, Effect of reducing manufacturing and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

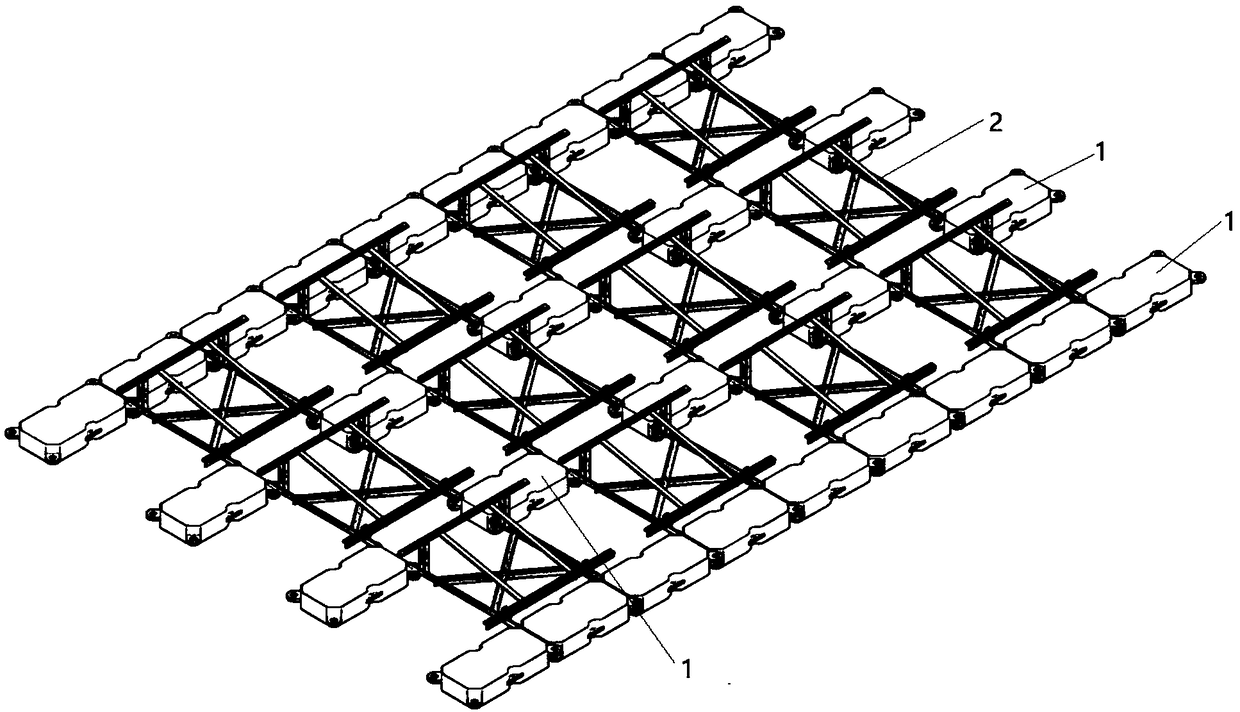

[0038] Such as Figure 1 to Figure 5 As shown, this embodiment provides a photovoltaic module support system, including a plurality of buoys 1, and also includes a steel structure component 2 for supporting the photovoltaic module (not shown in the figure), wherein the steel structure component is made of aluminum alloy material The resulting angle steel is fixedly connected by one or more of conventional methods such as welding, riveting or bolting.

[0039] Such as figure 1 with image 3 As shown, the buoy 1 is provided with a connecting ear 11 , and in order to ensure the strength of the connecting ear, the connecting ear 11 adopts a solid structure integrally formed with the buoy 1 .

[0040] The lower part of the steel structure component 2 is provided with a connection part, and the steel structure component 2 and the buoy 1 are fixedly connected to form a support unit through the connector inserted in the connection ear 11 and the connection part, and a plurality of s...

Embodiment 2

[0052] This embodiment is basically the same as Embodiment 1, the difference is that, as Image 6 As shown, the support unit includes a steel structure component 2 and two buoys 1, and the two ends of the steel structure component 2 are respectively fixed on the two connecting ears on the same side of the two buoys 1, and the multiple support units are composed of Figure 7 Support system shown.

[0053] Compared with embodiment 1, the number of buoys used in embodiment 2 is large, but the buoyancy provided is large, which can further meet the requirements of strong surge and bad weather for the support system.

Embodiment 3

[0055] Such as Figure 8 to Figure 12 As shown, the difference between this embodiment and Embodiment 1 is that the buoys are provided with connection ears for connecting with adjacent buoys, and adjacent buoys are connected by first bolts inserted in the adjacent connection ears.

[0056] At least one inner connection lug of the buoy is respectively provided along the two sides of the buoy away from the adjacent buoy, and the inner connection lug of the buoy is provided with a buoy connection hole for matching with the steel structure connection hole at the bottom of the steel structure component as a connection structure; The buoy is connected to the steel structure assembly as a whole through the second bolts used as connecting pieces inserted in the connection holes of the buoy and the steel structure connection holes.

[0057] Such as Figure 8 As shown, the steel structure components 2 and the buoys 1 are arranged at intervals along one direction (that is, arranged at i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com