Method for detecting position of mask holder on measuring table

A technology of mask fixtures and masks, which is applied in the field of calibrating the measurement system used for this purpose, can solve the problems of measurement error, process error influence, fixture edge roughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

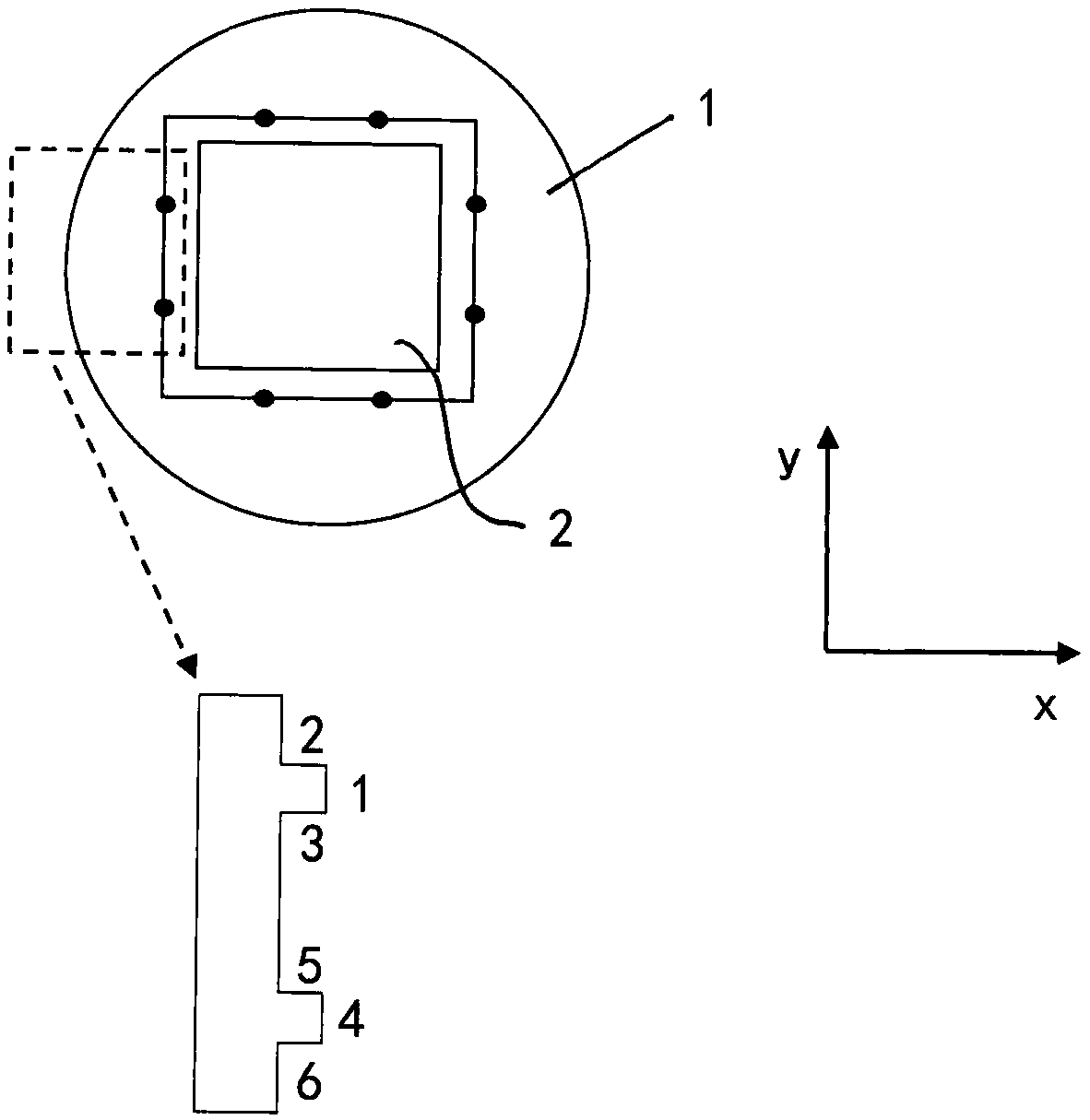

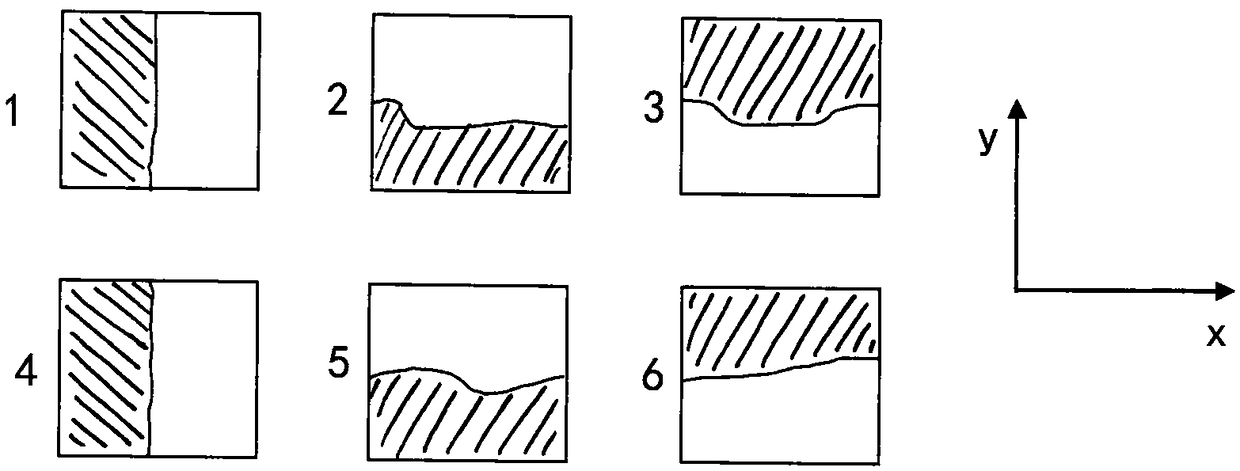

[0042] In the example schematic, figure 1 The mask holder 1 is shown with the mask 2 arranged therein on a three-point bearing not shown in the figure. Typically, a mask holder 1 is used to receive a mask 2 to be measured and to carry this mask 2 on a measurement table of a measurement system for the duration of the measurement, for successively regular reception of different masks. As already mentioned, precise knowledge about the position of the mask holder 1 on the measurement table is necessary for precise and reproducible measurements of structures on the mask 2 . However, a systematic error is involved in the establishment of the position of the mask holder 1 on the measurement table, which is due to the structure of the mask holder 1 itself. For the purpose of measuring the mask holder 1 on the measuring table, the measuring points shown in the figure but not respectively marked are used on the inner side of the mask holder 1 facing the mask 2 .

[0043] From the part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com