Crankshaft machining device and machining method

A kind of crankshaft processing and crankshaft technology, which is applied in the field of crankshaft processing devices, can solve the problems of small eccentricity of eccentric shaft section, low precision, complicated operation, etc., and achieve the effect of ensuring processing accuracy, improving work efficiency, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

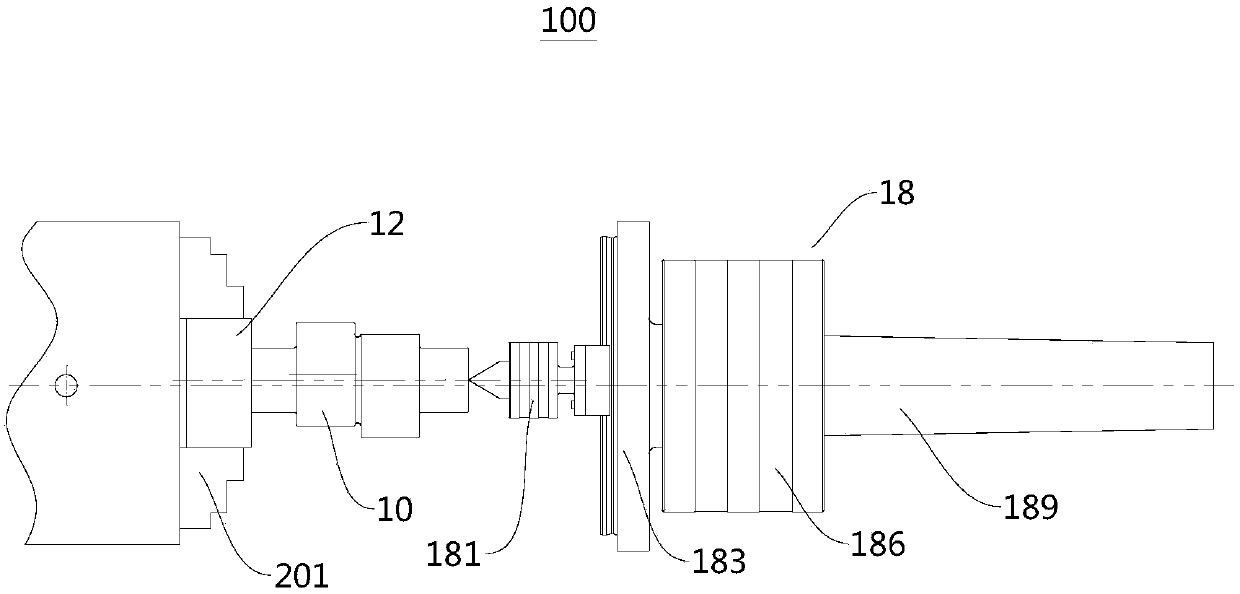

[0054] figure 1 A schematic structural view of the crankshaft processing device 100 provided by the present invention, such as figure 1 As shown, the crankshaft processing device 100 provided by Embodiment 1 of the present invention includes a crankshaft eccentric sleeve assembly 12 and an adjustable eccentric tip assembly 18 .

[0055] Use this crankshaft processing device 100 to process the crankshaft 10 to be processed, use the machine tool chuck 201 to clamp and fix one end of the crankshaft 10 to be processed through the crankshaft eccentric bushing assembly 12, and the other end of the crankshaft 10 to be processed is passed through the adjustable eccentric tip assembly 18 Clamping can realize high-efficiency and high-precision batch processing. The processed crankshaft 10 can be applied to industrial robot reducers with high processing accuracy and can effectively ensure the accuracy of eccentricity.

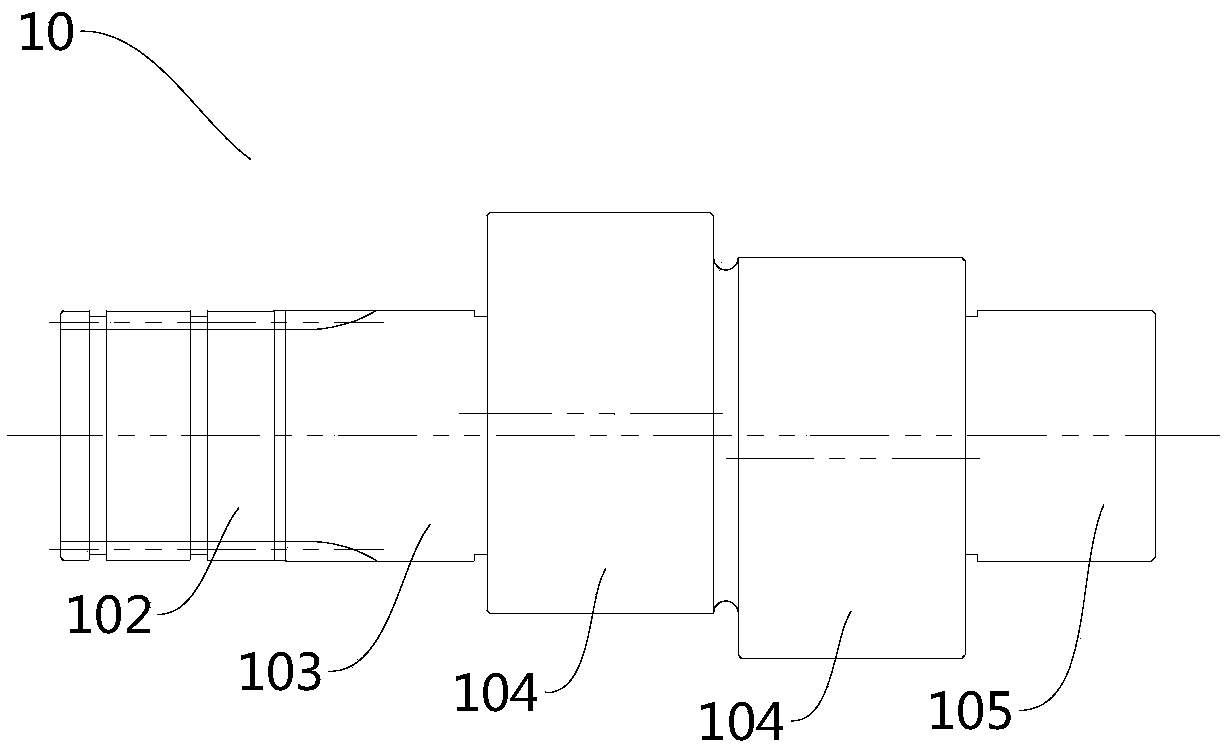

[0056] figure 2 is a structural schematic diagram of the cranksha...

Embodiment 2

[0087] Embodiment 2 of the present invention provides a crankshaft processing method for processing a crankshaft 10 having a spline shaft section 102 and a bearing installation section, and the specific description is as follows:

[0088] Preparatory steps: clamp the crankshaft 10 to be processed on the machine tool chuck 201 through the crankshaft eccentric bushing assembly 12, make the spline shaft section 102 cooperate with the spline collet 125, and place the Morse taper shank in the adjustable eccentric tip assembly 18 1896 installed in the taper hole of the lathe tailstock.

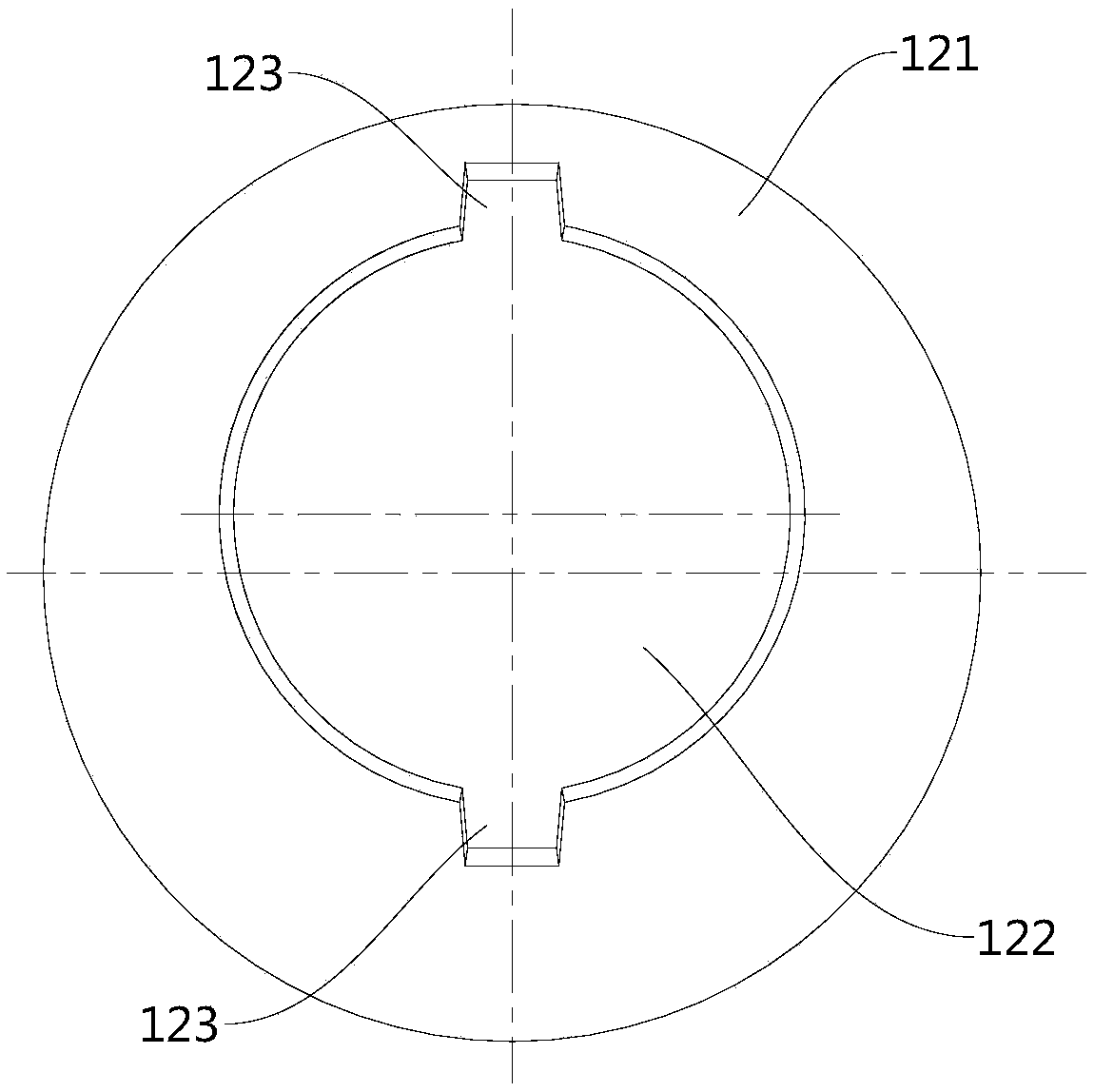

[0089] One end of the crankshaft 10 to be processed is assembled on the eccentric shaft sleeve 121, and then the whole is clamped in the chuck 201 of the machine tool, and the other end of the crankshaft 10 to be processed is tightened by the adjustable eccentric center. A first split groove 127 and a second split groove 128 are provided, the split groove communicates with the spline hole, the splin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com