Foaming ceramic core composite material sandwich structure and forming method thereof

A foamed ceramic and sandwich structure technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc. Simple processing and molding, low-density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 A foamed ceramic core composite sandwich structure, prepared by the following method:

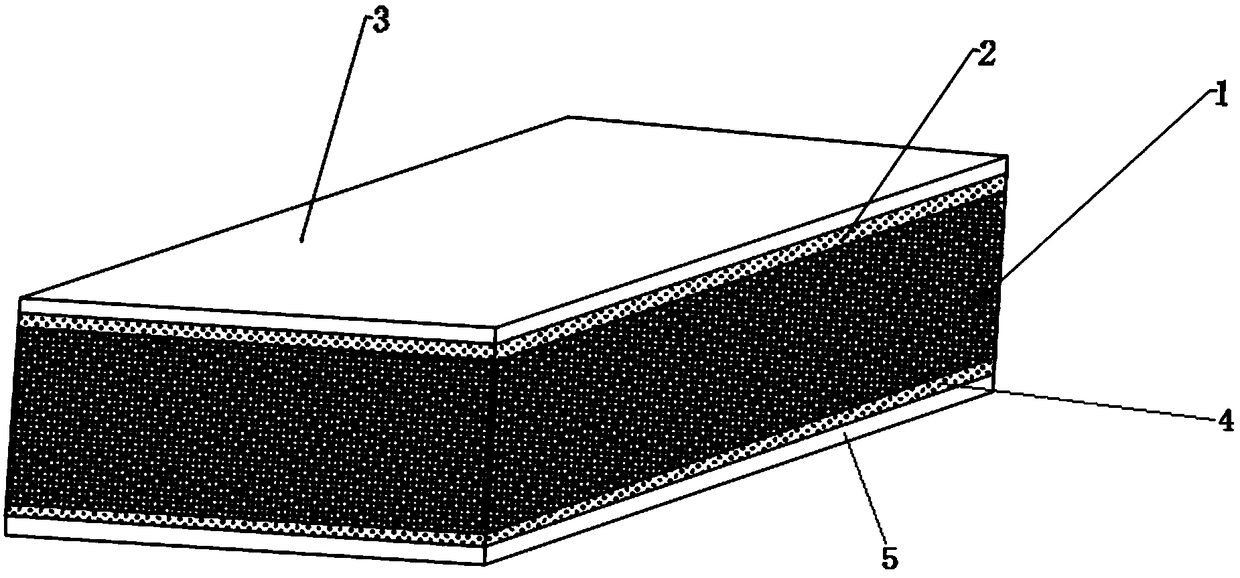

[0029] refer to figure 1 , a foamed ceramic core composite sandwich structure comprising a thickness of 40mm and a bulk density of 0.28g / cm 3 The foamed ceramic core material 1, the first glass fiber reinforced flame-retardant phenolic resin composite material plate 3 with a thickness of 5mm, the second glass fiber reinforced flame-retardant phenolic resin composite material plate 5 with a thickness of 5mm, and the foamed ceramic core material 1 and the first flame-retardant polymer bonding layer 2 between the first glass fiber reinforced flame-retardant phenolic resin composite material plate 3, the foamed ceramic core material 1 and the second glass fiber reinforced flame-retardant phenolic resin composite material plate 5 The second flame-retardant polymer adhesive layer 4 between them. The material of the first flame-retardant polymer adhesive layer 2 and the second f...

Embodiment 2

[0038] Embodiment 2 A foamed ceramic core composite sandwich structure, prepared by the following method:

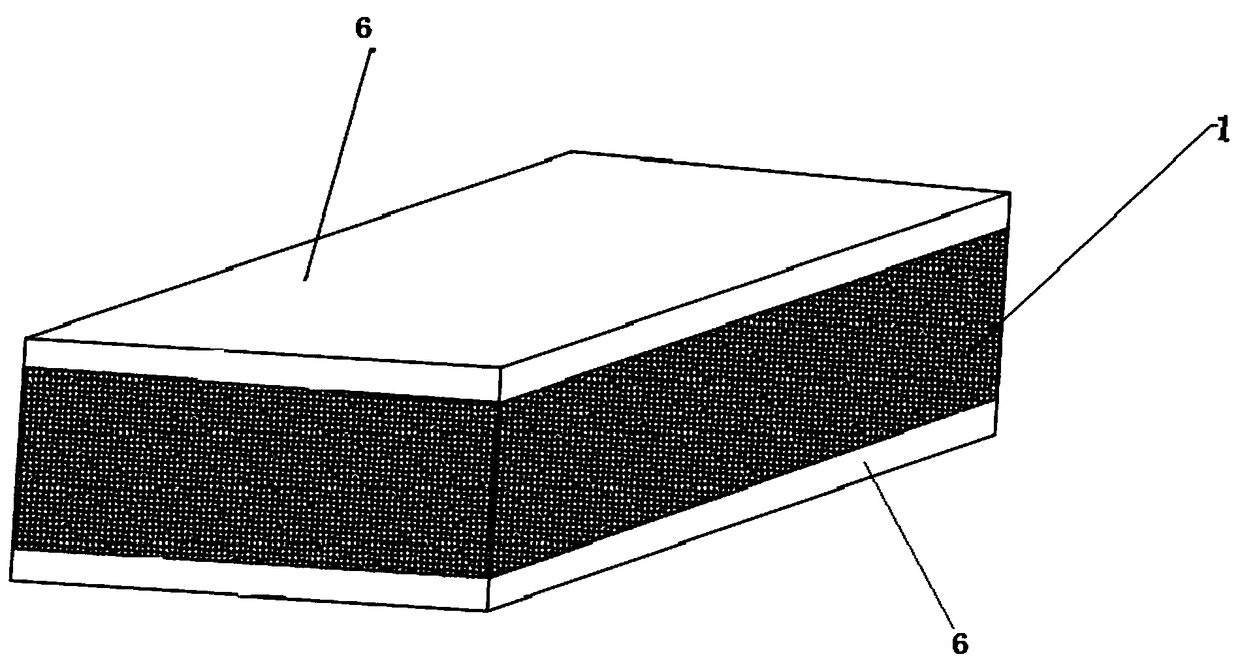

[0039] refer to figure 2 , a foamed ceramic core composite sandwich structure comprising a thickness of 30mm and a bulk density of 0.56g / cm 3 The foamed ceramic core material 1 and the prepreg 6 of fiber-reinforced flame-retardant epoxy resin composite material located on the upper surface and the lower surface of the foamed ceramic core material 1 respectively. The molding method of this sandwich structure is: impregnating the fiber cloth with flame-retardant epoxy resin to form a prepreg 6 of fiber-reinforced flame-retardant epoxy resin composite material, and laying it on the upper surface and the lower surface of the foamed ceramic core material 1 respectively. The prepreg 6 of the fiber-reinforced flame-retardant epoxy resin composite material, so that the prepreg 6 of the fiber-reinforced flame-retardant epoxy resin composite material and the foamed ceramic core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com