A rainy day waterproof courier drone

A drone and courier technology, applied in antifouling/underwater coatings, rotorcraft, motor vehicles, etc., can solve the problems of easy entry of rainwater and the impact of courier objects, and achieve the effect of flexible shielding range and rain prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

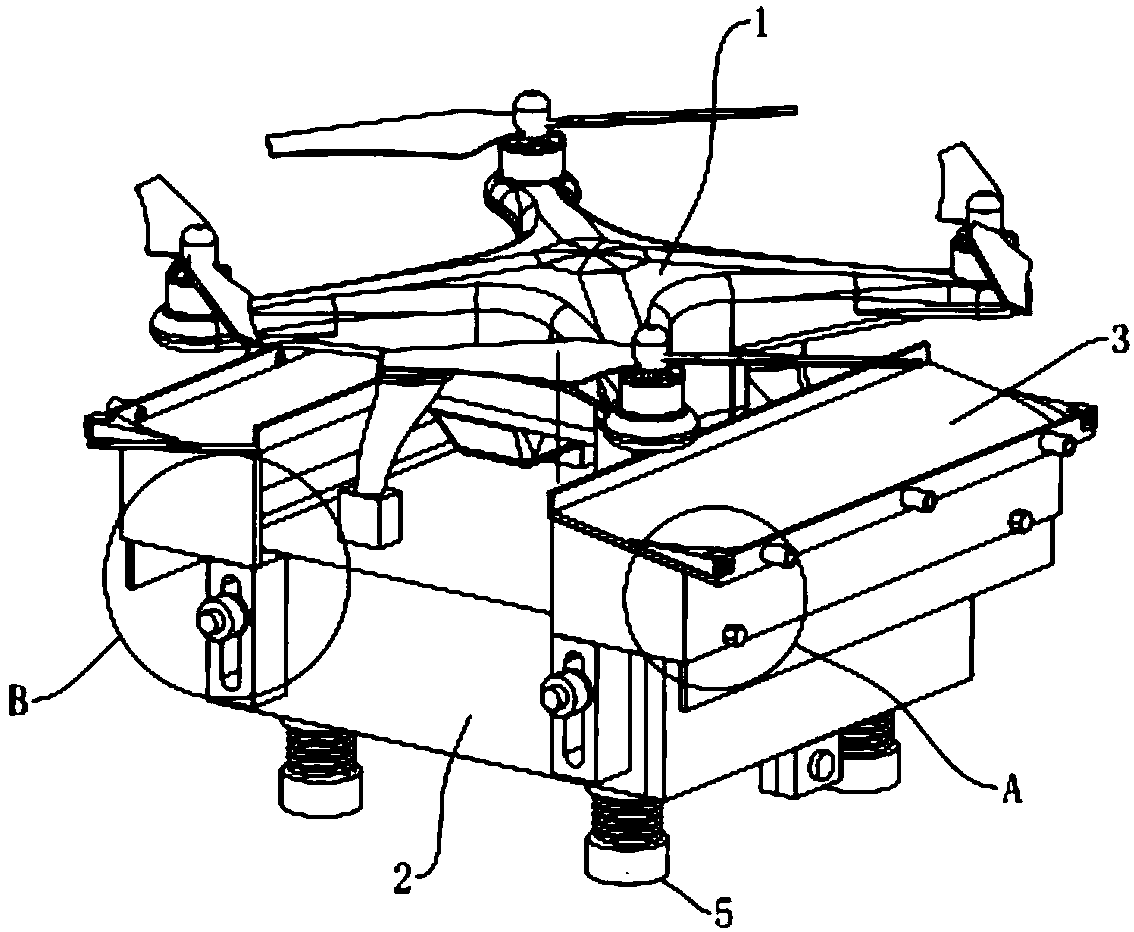

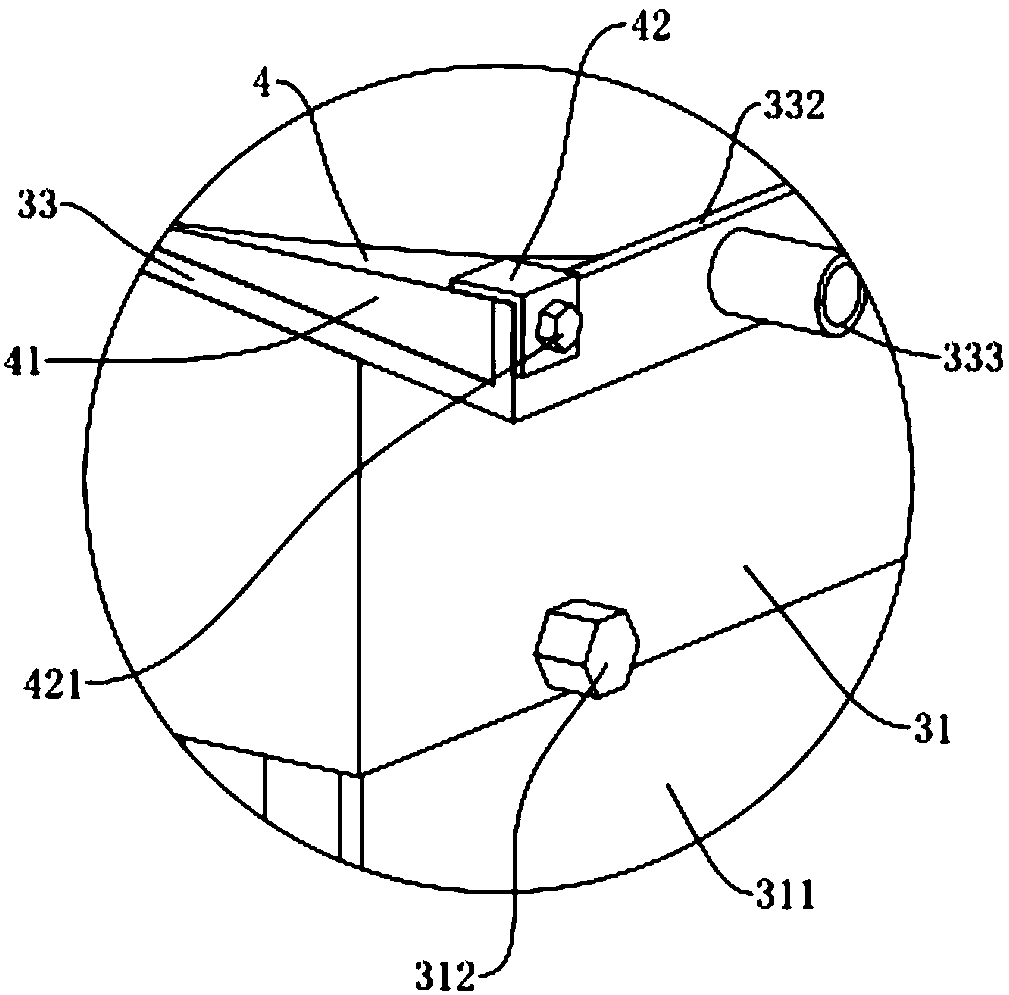

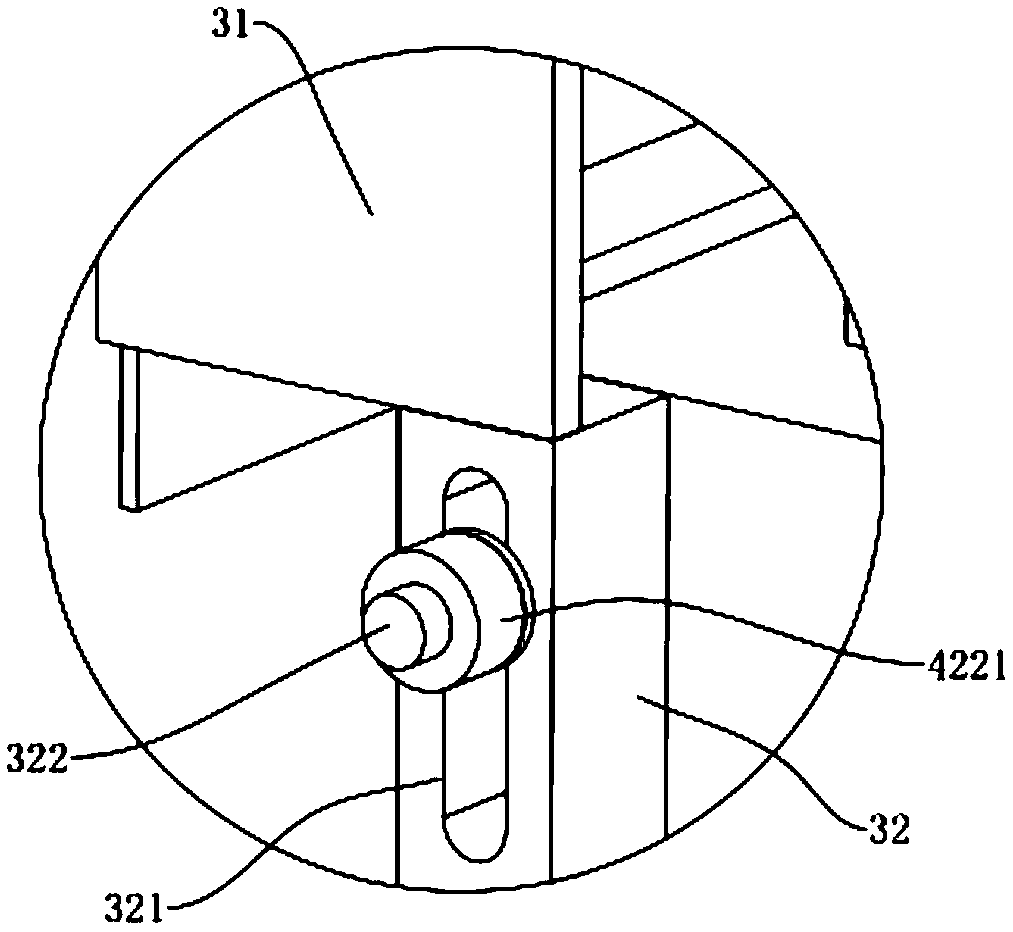

[0040] Such as Figure 1 to Figure 7 As shown, a rainy weather waterproof express delivery drone includes a drone body 1. The model of the drone body 1 is the DJI drone "MAV I C", which is a multi-rotor drone with a payload of 10 kg. , in order to realize the function of rainproof express delivery, a material box 2 for placing express delivery is fixed under the drone body 1, wherein the material box 2 has two openings 21 at the front and rear, and the express delivery items can be taken out from the opening 21 on the material box 2 At the same time, the material box 2 is respectively connected with a box cover 22 at the two openings 21. Since rainwater can be poured into the material box 2 from the opening 21, two groups of material boxes 2 are also arranged on the material box 2 to cover the material box 2. The opening 21 and the shielding part 3 of the box cover 22, the material box 2 fixed under the drone body 1 can be used to place the courier, and the courier can be take...

Embodiment 2

[0044] The difference from Example 1 is that the outside of the material box 2 is coated with an anti-fouling coating. Since the material box 2 has been flying in the air for a long time, the outside of the material box 2 will inevitably become dirty. In order to prevent pollutants from being firmly The material box 2 is stuck on the outside of the material box 2, and at the same time, in order to facilitate cleaning of the material box 2, an antifouling coating is also coated on the outside of the material box 2, so a preparation method for the antifouling coating is provided, which has a preparation process The advantages of short and simple preparation, wherein the preparation method of the external antifouling coating of the material box 2 is as follows:

[0045] Take the following raw materials by weight for each component: 30 parts of acrylic resin, 24 parts of polyurethane, 14 parts of polyvinyl chloride, 60 parts of acetone, 20 parts of hydroxyethylated fatty amine, 4 p...

Embodiment 3

[0052] The difference from Example 2 is the preparation of the external antifouling coating of material box 2, wherein the preparation method of the antifouling coating is as follows:

[0053] Take the following raw materials for each component by weight: 31 parts of acrylic resin, 25 parts of polyurethane, 15 parts of polyvinyl chloride, 64 parts of acetone, 22 parts of hydroxyethylated fatty amine, 5 parts of ethyl propionate, diphenylethyl ether 7 parts of ketone, 6 parts of ethyl methacrylate, 4 parts of terephthalic acid;

[0054] S1. Refining: fully mix acrylic resin, polyurethane, polyvinyl chloride and acetone at a high speed, put it in an internal mixer at 145°C for 2.5 hours, and obtain the first pre-preparation solution;

[0055] S2. Preparation of the second pre-preparation solution: after the plasticization is completed, add hydroxyethylated fatty amine, ethyl propionate, ethyl methacrylate and terephthalic acid to the first pre-preparation solution obtained in S1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com