Construction method for AAC block free-loading wall

A block and free technology, used in building components, building insulation materials, construction and other directions, can solve the problem that the wall cannot be freely loaded, slotted, opened, plastered and veneer bricks, affecting the durability of the construction wall, The plastering layer is easy to hollow out and fall off, so as to reduce masonry waste, controllable deformation, and concise interface blocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

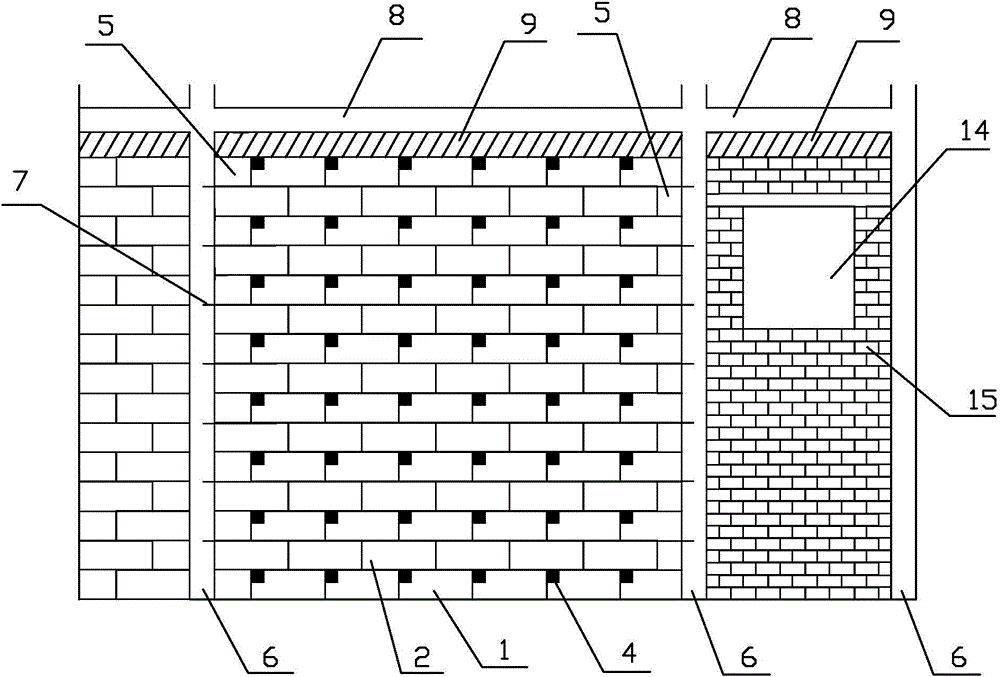

[0030]Embodiment 1: The AAC block free-loading wall built in this embodiment is used as the outer wall, and the construction method of the AAC block free-loading wall includes the following steps:

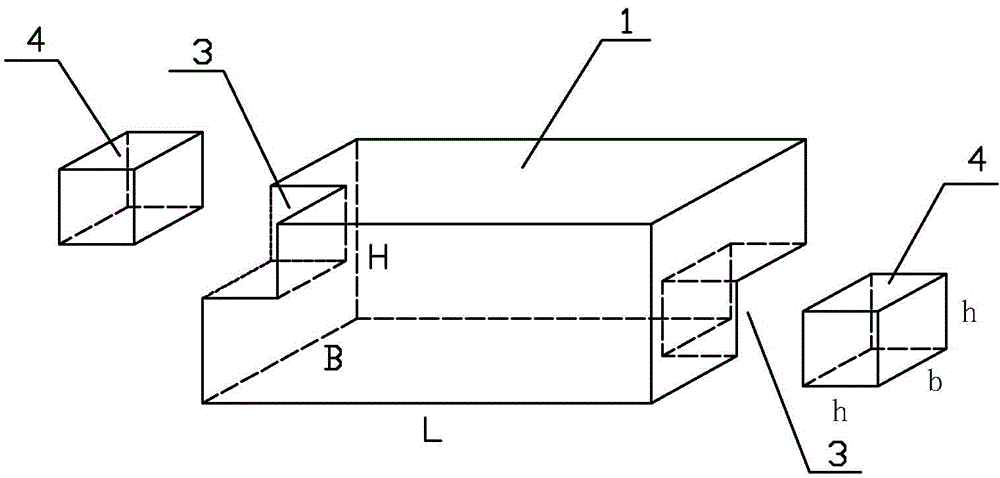

[0031] ①. Prefabricated concrete block 4, the concrete block 4 adopts C20 plain concrete block, the length, height, and thickness of the concrete block 4 are 100mm, 100mm, and 100mm respectively; the standard autoclaved sand aerated concrete block is produced by a special factory, and its length , height, and thickness are 600mm, 250mm, and 240mm respectively; when the blocks and concrete blocks enter the site, they are stacked according to the order of the AAC block material list, and are packed with plastic film to prevent rain. It should be noted that when the blocks are stacked, the bottom should be raised. Blocks wetted by rain should not be placed on the wall immediately, and the moisture content of the blocks on the upper wall should not be greater than 25%. According to the ...

Embodiment 2

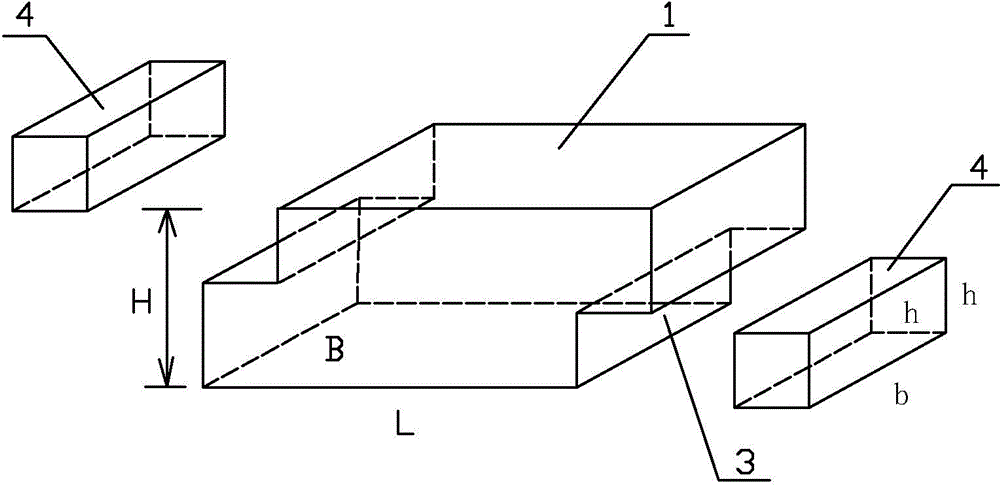

[0047] Embodiment 2: The AAC block free-loading wall built by this embodiment is used as the inner wall, and the AAC block free-loading wall construction method, the length, height and thickness of the prefabricated concrete block 4 are respectively 100mm, 100mm, and 240mm; standard After the autoclaved sand aerated concrete blocks are pre-dried and shrunk in the stockyard, the blocks are processed according to the order of the material list, and the standard autoclaved sand aerated concrete blocks are obliquely and symmetrically cut off two rectangular parallelepiped blocks along the length direction to form Two cuboid gaps 3, the length, height, and thickness of the gaps 3 are also 100mm, 100mm, and 240mm respectively, and the two gaps are arranged diagonally and symmetrically to form the first block 1, and a gap 3 is located on the upper left of the first block 1 part, another notch 3 is located at the lower right part of the first block 1, such as image 3 shown. All the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com