Garbage bucket cleaning system with automatic lubrication function, and using method thereof

An automatic lubrication and cleaning system technology, applied in the field of trash can cleaning system, can solve the problems of water waste, poor cleaning effect, single cleaning method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

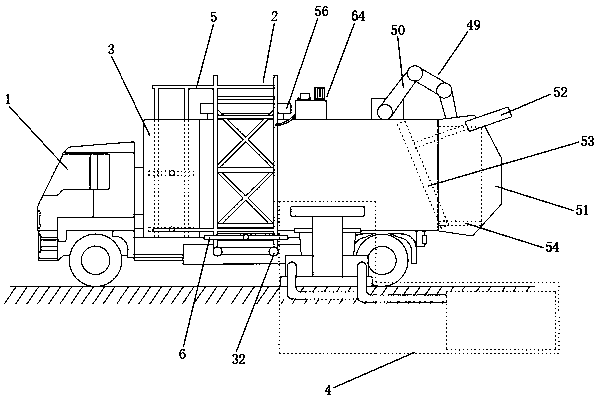

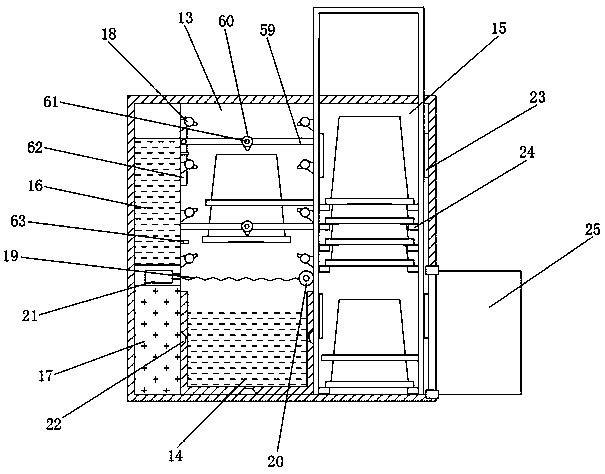

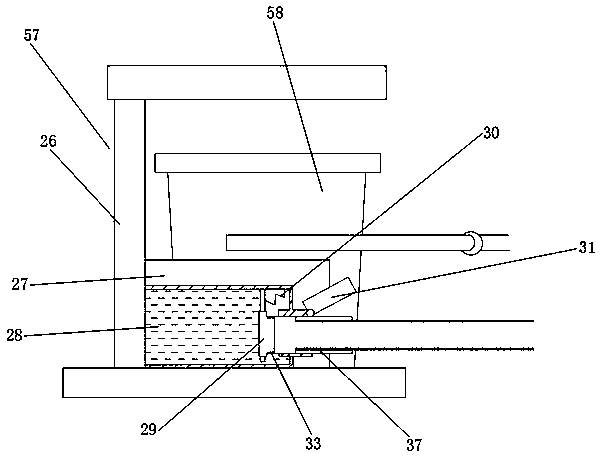

[0043] Embodiment 1: (no anti-slip protrusion 12, no dust cover 31)

[0044]As shown in the drawings of the description, an automatic lubricating trash can cleaning system includes a car body 1, a barrel clamping device 2, a cleaning system 3, a sewage purification circulation system 4 and a control system; The top is provided with a garbage inlet 56 and a track lubricating oil cylinder 64, and the tail is provided with a garbage compression device 49; the cleaning system 3 is arranged at the front end of the car body 1 compartment, close to the garbage inlet 56; the barrel clamping device 2 includes Bucket clamp movable track 5 and bucket clamp 6; the bucket clamp track 5 is a double-track ring-shaped closed track, which is initially arranged on the side of the car body 1 and passes through the cleaning system 3; the bucket clamp 6 has two groups , are all placed horizontally in the middle of the movable track 5 of the bucket clamp; the cleaning system 3 includes a spray wash...

Embodiment 2

[0055] Embodiment 2: (with anti-slip protrusion 12, without dust cover 31)

[0056] The second embodiment is basically the same in structure and principle as the first embodiment, except that the bucket clip 6 also includes anti-slip protrusions 12; The anti-slip protrusion 12 plays an anti-skid role when the trash can 58 is clamped.

Embodiment 3

[0057] Embodiment 3: (without anti-skid protrusion 12, with dustproof cover 31)

[0058]Embodiment 3 is basically the same in structure and principle as Embodiment 1, except that a dustproof cover 31 is hinged at the front ends of the clear water port 28 and the sewage port 38 . The dustproof cover 31 acts as a dustproof function for the clean water port 28 and the sewage port 38 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com