Smelting method of high-toughness and high-strength casting-state ductile cast iron

A technology of ductile iron and high toughness, applied in the field of casting, can solve the problems of low mechanical properties of as-cast ductile iron, and achieve the effects of improved mechanical properties, low production cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

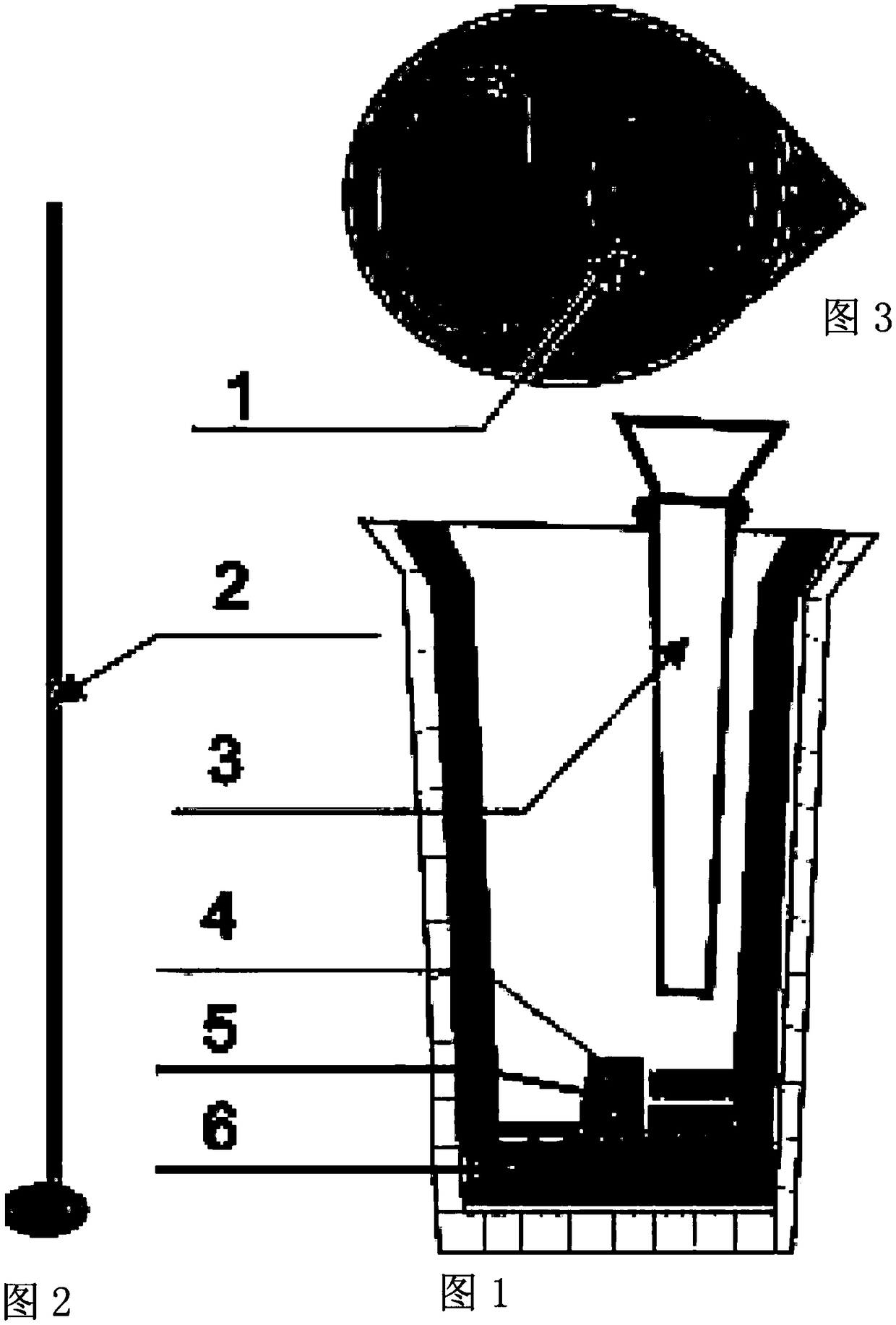

Image

Examples

example 1

[0047] A total of 800kg of molten iron is melted and 800kg of spheroidizing is produced;

[0048] Furnace charge ratio: pig iron 240kg, scrap steel 280kg, furnace charge 280kg, recarburizer 10kg (the recarburizer is placed in the middle and lower part of the intermediate frequency furnace), and the furnace temperature is controlled at 1535°C±15°C.

[0049] Spheroidization treatment: 9.6kg nodulizer Inoculant: 5kg Covering agent: 8kg Secondary inoculant: 4.5kg Third inoculation: (inoculation with flow) 0.88kg Copper: 1.7kg Tin: 0.15kg.

[0050]Before spheroidizing, preheat the spheroidizing ladle and pouring ladle to 600°C-800°C (dark red or red),

[0051] Add the spheroidizing agent, inoculant, and covering agent into the spheroidizing bag in sequence, and beat tightly. Put copper and tin into the spheroidizing bag. Put the molten iron into the spheroidizing bag and cover the spheroidizing bag cover. After the reaction is stable, pour the molten iron into the pouring bag (te...

example 2

[0057] A total of 1000KG molten iron is melted and 1000kg is spheroidized;

[0058] Furnace charge ratio: 250kg of pig iron, 350kg of scrap steel, 400kg of returned charge, 13kg of recarburizer (the recarburizer is placed in the middle and lower part of the intermediate frequency furnace), and the furnace temperature is controlled at 1545°C±15°C.

[0059] Spheroidization treatment: 12.5kg nodulizer, inoculant: 6kg, covering agent: 10kg, secondary inoculant: 5.5kg, third inoculation: (inoculation with flow) 1.2kg, copper: 2kg, tin: 0.17kg.

[0060] Before spheroidizing, preheat the spheroidizing ladle and pouring ladle to 600°C-800°C (dark red or red),

[0061] Add the spheroidizing agent, inoculant, and covering agent into the spheroidizing bag in sequence, and beat tightly. Put copper and tin into the spheroidizing bag. Put the molten iron into the spheroidizing bag and cover the spheroidizing bag cover. After the reaction is stable, pour the molten iron into the pouring ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com