Stabilizing processing technology for 5052 aluminum alloy

A technology for stabilizing aluminum alloys, which is applied in the field of aluminum alloy manufacturing, can solve problems such as unfavorable control and narrow processing window, and achieve the effects of increasing stability, reducing production costs, and stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A stabilization treatment process for 5052 aluminum alloys, comprising the steps of:

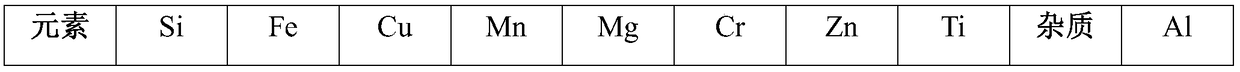

[0029] A. Prepare 5052 aluminum alloy raw materials according to the following ratios in parts by weight:

[0030] element

Si

Fe

Cu

mn

Mg

Cr

Zn

Ti

Impurities

Al

content

0.133

0.309

0.003

0.022

2.356

0.23

0.004

0.019

0.05

margin

[0031] Adding the prepared 5052 aluminum alloy raw materials into a melting furnace for uniform mixing and melting into a liquid aluminum alloy to obtain an aluminum alloy melt;

[0032] B. Refining the aluminum alloy melt at 740°C for 20 minutes, melting and casting the refined aluminum alloy melt into aluminum alloy ingots, during which the aluminum alloy melt is filled into the bottom of the melting furnace High-purity nitrogen gas removes impurity gases in the aluminum alloy melt. During the refining process of the aluminum alloy melt, an aluminum titanium boron wire...

Embodiment 2

[0038] A stabilization treatment process for 5052 aluminum alloys, comprising the steps of:

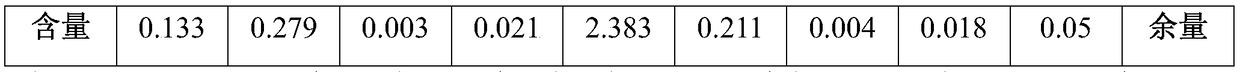

[0039] B. Prepare 5052 aluminum alloy raw materials according to the following ratios in parts by weight:

[0040] element

Si

Fe

Cu

mn

Mg

Cr

Zn

Ti

Impurities

Al

content

0.125

0.289

0.003

0.019

2.411

0.23

0.004

0.024

0.05

margin

[0041]Adding the prepared 5052 aluminum alloy raw materials into a melting furnace for uniform mixing and melting into a liquid aluminum alloy to obtain an aluminum alloy melt;

[0042] B. Refining the aluminum alloy melt at 740°C for 20 minutes, melting and casting the refined aluminum alloy melt into aluminum alloy ingots, during which the aluminum alloy melt is filled into the bottom of the melting furnace High-purity nitrogen gas removes impurity gases in the aluminum alloy melt. During the refining process of the aluminum alloy melt, an aluminum-titanium-boron wire ...

Embodiment 3

[0048] A stabilization treatment process for 5052 aluminum alloys, comprising the steps of:

[0049] C, prepare 5052 aluminum alloy raw materials according to the following ratios in parts by weight:

[0050] element

Si

Fe

Cu

mn

Mg

Cr

Zn

Ti

Impurities

Al

content

0.123

0.299

0.003

0.021

2.256

0.232

0.004

0.023

0.05

margin

[0051] Adding the prepared 5052 aluminum alloy raw materials into a melting furnace for uniform mixing and melting into a liquid aluminum alloy to obtain an aluminum alloy melt;

[0052] B. Refining the aluminum alloy melt at 740°C for 20 minutes, melting and casting the refined aluminum alloy melt into aluminum alloy ingots, during which the aluminum alloy melt is filled into the bottom of the melting furnace High-purity nitrogen gas removes impurity gases in the aluminum alloy melt. During the refining process of the aluminum alloy melt, an aluminum-titanium-boron wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com