Fuel injection rate measuring system and method based on Zeuch pressure magnetic method

A measurement system and rate technology, applied in the field of fuel spray diagnosis, can solve the problems of high pipe length requirements, high equipment maintenance costs, high coordination requirements, etc., to eliminate non-periodic oscillation, facilitate disassembly and replacement, and ensure cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

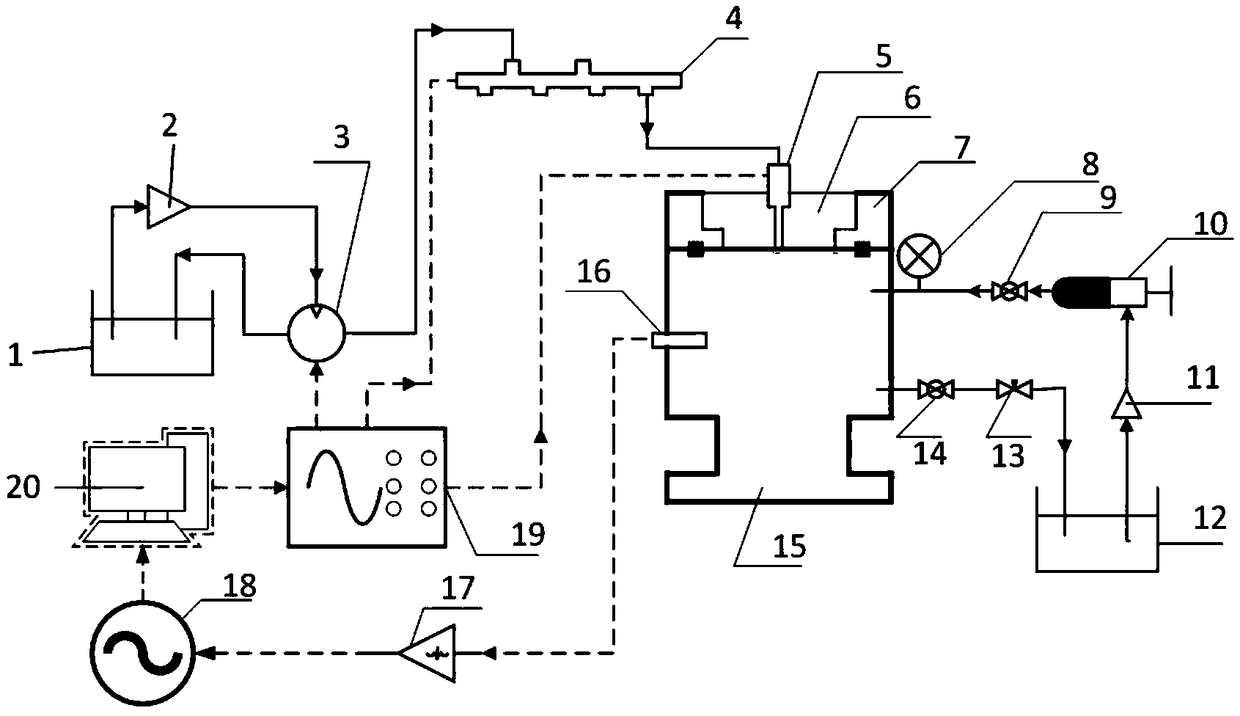

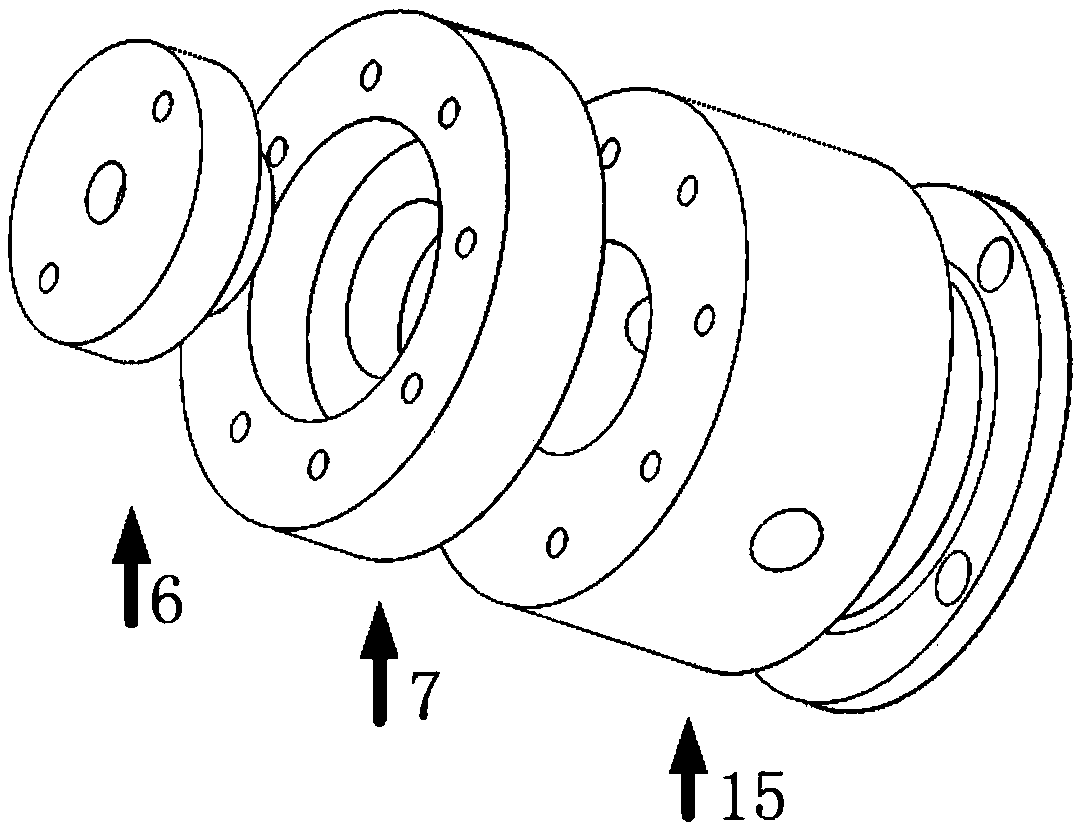

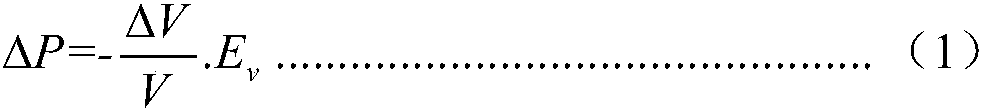

[0042] Such as figure 1 and figure 2 As shown, the present invention provides a fuel injection rate measurement system based on the principle of Zeuch piezomagnetic method, which is used to accurately measure the fuel injection rate curve under different working conditions, and has a good response effect to different stages of the multiple injection process . The system covers the generation of the fuel injection process of the injector, the collection of the pressure electrical signal caused by the fuel injection in the cavity, the amplification of the pressure electrical signal and the conversion process of the voltage and current, and the filtering of the pressure electrical signal by the post-processing method. And the complete test process of differential operation and calibration of the pressure electrical signal to restore the fuel injection signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com