Method for detecting industrial process faults basing on multi-sampling rate factor analysis model

A factor analysis model and multi-sampling rate technology, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of unable to realize the utilization of data information, affecting the accuracy of fault detection, and unable to realize the complete interpretation of massive data information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0123] Taking the papermaking wastewater treatment process as an example, the present invention is further described:

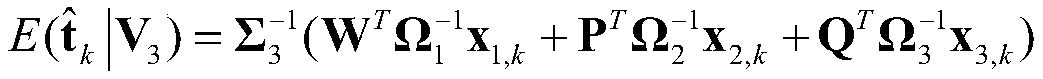

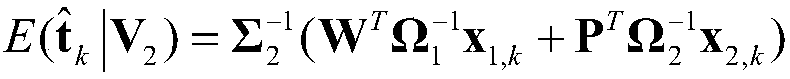

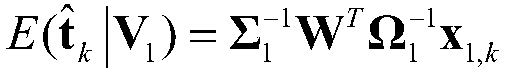

[0124] A method for fault detection of papermaking wastewater treatment process based on multi-sampling rate factor analysis model. This method aims at the fault detection problem of papermaking wastewater treatment process. Factor analysis model. The model structure is estimated by the expectation maximization algorithm. On this basis, two detection statistics T 2 and SPE and their corresponding statistical limits and SPE lim . The online papermaking wastewater treatment process is detected to obtain test samples, and then the latent variables and prediction errors of the test samples can be estimated by using the existing model structure, and the corresponding statistics are calculated to obtain the final fault detection results.

[0125] The present invention is a papermaking wastewater treatment process fault detection method based on a multi-sampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com