A magnetic levitation motor housing with high heat dissipation performance

A motor shell and magnetic levitation technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of insufficient heat dissipation of the device, energy consumption, machine damage, etc., to improve convenience, improve environmental protection, The effect of efficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

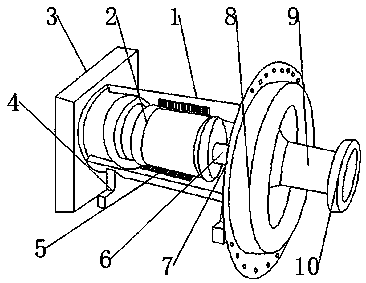

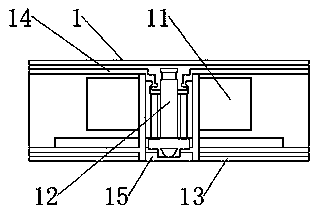

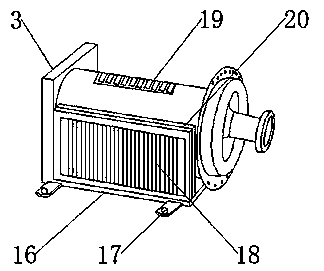

[0022] Example 1: See Figure 1-3 , the present invention provides a technical solution: a magnetic levitation motor housing with high heat dissipation performance, including a housing body 1, a magnetic levitation motor 2, a side baffle 3, a housing support 4, an inner cooling plate 5, a linkage shaft 6, and a flange 7. Ventilation pipe 8, coupling pipe 9, connecting rubber ring 10, built-in fan 11, internal liquid storage pipe 12, aluminum shell material 13, liquid tank 14, buffer sheet 15, base 16, fixed block 17, solar energy Plate 18, outer cooling plate 19 and light energy conversion plate 20, a magnetic levitation motor 2 is provided in the middle of the inner side of the housing body 1, a linkage shaft 6 is provided at one end of the magnetic levitation motor 2, and a side baffle 3 is provided on one side of the housing body 1. The bottom of the side baffle 3 is provided with a base 16, the bottom of the base 16 is provided with a housing support 4, the top of the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com