Reproduced coffee cream and preparation method thereof

A technology of cream and anhydrous cream, applied in cream preparations, dairy products, applications, etc., to improve the quality of life and solve the effect of unstable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

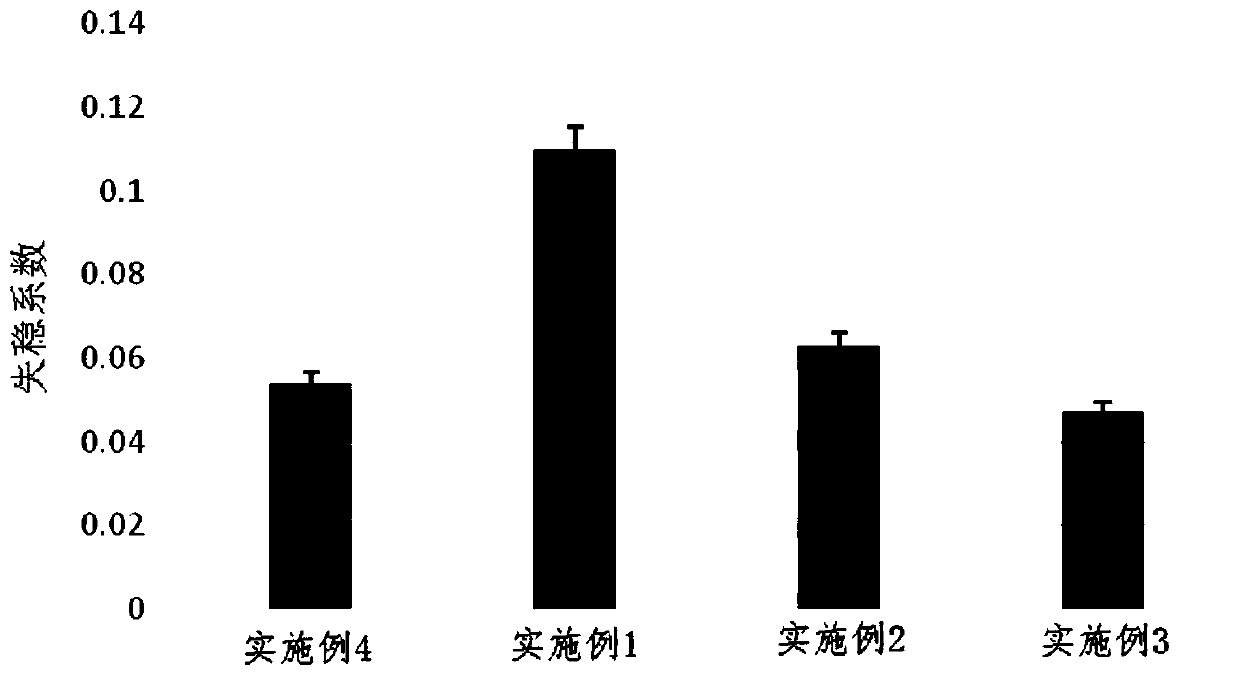

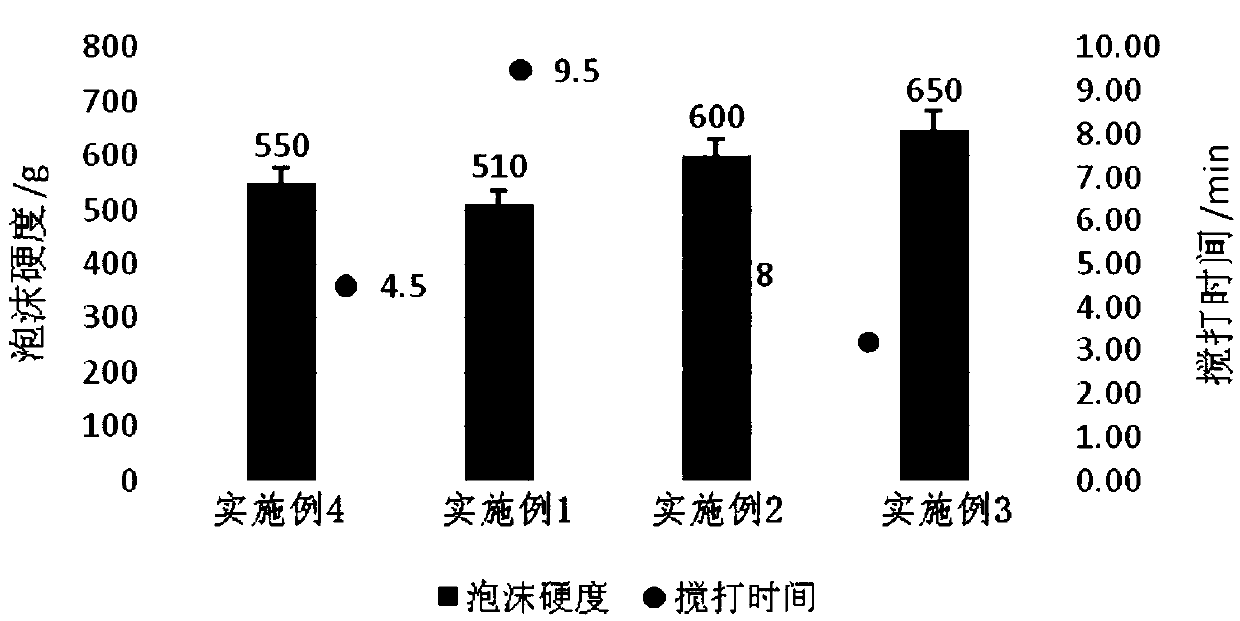

Embodiment 1

[0038] This embodiment provides a reconstituted cream, which is prepared from the following components in parts by weight: 36 parts of low-melting anhydrous butter, 2.5 parts of milk protein concentrate, 0.05 part of Tween, 0.1 part of lecithin, and triglyceride (purchased from Cargill Co., Ltd.) 0.1 part, monoglyceride (purchased from Cargill Co., Ltd.) 0.3 part, microcrystalline cellulose 0.5 part and water 60.9 parts.

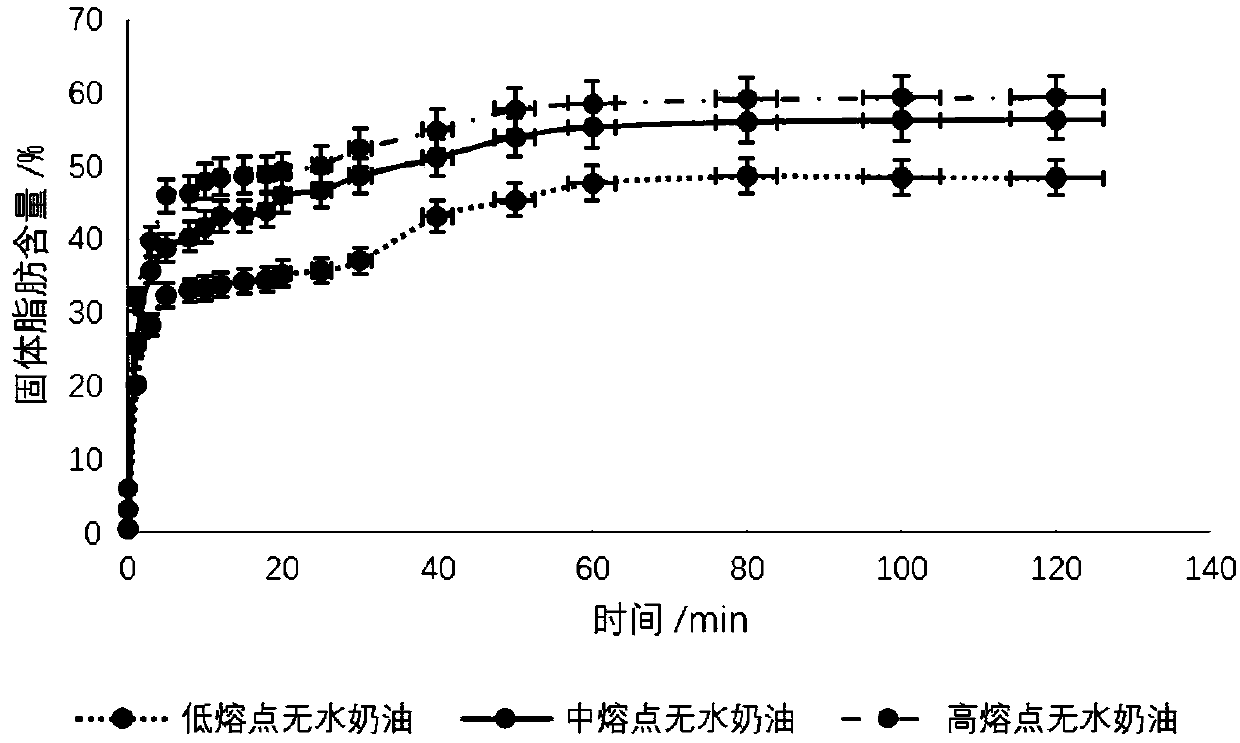

[0039] Among them, the low-melting anhydrous butter is obtained by fractionating from anhydrous butter. The specific fractionation method is as follows: raise the temperature of the anhydrous butter to 25°C and place it at a constant temperature for 8-24 hours, and take out the liquid phase to obtain the low-melting cream. Anhydrous butter with melting point; continue to heat up the remaining solid components to 35°C and keep the temperature at this temperature for 8-24 hours to separate the solid and liquid phases. The liquid phase is anhydrous butter with a...

Embodiment 2

[0050] This embodiment provides a reconstituted cream, which is prepared from the following components in parts by weight: 36 parts of medium melting point anhydrous cream, 1 part of skimmed milk powder (purchased from Fonterra), 0.05 part of Tween, and 0.5 part of lecithin , 0.2 parts of triglycerides, 0.5 parts of monoglycerides, 0.08 parts of carrageenan, 0.05 parts of guar gum, 0.04 parts of xanthan gum and 61.58 parts of water.

[0051] Wherein, the middle melting point anhydrous butter is obtained by fractionating from anhydrous butter, and the specific fractionation method is the same as that in Example 1.

[0052] This embodiment also provides the preparation method of the above-mentioned reconstituted cream, comprising the following steps:

[0053] (1) dissolving the skim milk powder in half of the water to obtain a protein dispersion;

[0054] (2) adding carrageenan, guar gum and xanthan gum to the remaining water for high-speed dispersion to obtain a stabilizer col...

Embodiment 3

[0059] This embodiment provides a reconstituted cream, which is prepared from the following components in parts by weight: 36 parts of high melting point anhydrous butter, 1.5 parts of skim milk powder, 0.1 part of Tween, 0.5 part of lecithin, 0.2 part of triglyceride 0.5 parts of monoglyceride, 0.5 parts of microcrystalline cellulose and 60.7 parts of water.

[0060] Wherein, the high melting point anhydrous butter is obtained by fractionating from anhydrous butter, and the specific fractionation method is the same as that in Example 1.

[0061] This embodiment also provides the preparation method of the above-mentioned reconstituted cream, comprising the following steps:

[0062] (1) dissolving the skim milk powder in half of the water to obtain a protein dispersion;

[0063] (2) adding microcrystalline cellulose to the remaining water for high-speed dispersion to obtain a stabilizer colloidal emulsion;

[0064] (3) Heating the high melting point anhydrous butter to over 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com