Method for preparing starch-protein complex having digestion resistance and high nutrition

A high-nutrition, anti-digestion technology, applied in the field of starch-protein complex preparation, can solve the problems of cumbersome process and poor anti-digestion effect of starch, so as to achieve rich sources of raw materials, promote short-range ordered structure, and control postprandial blood sugar effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

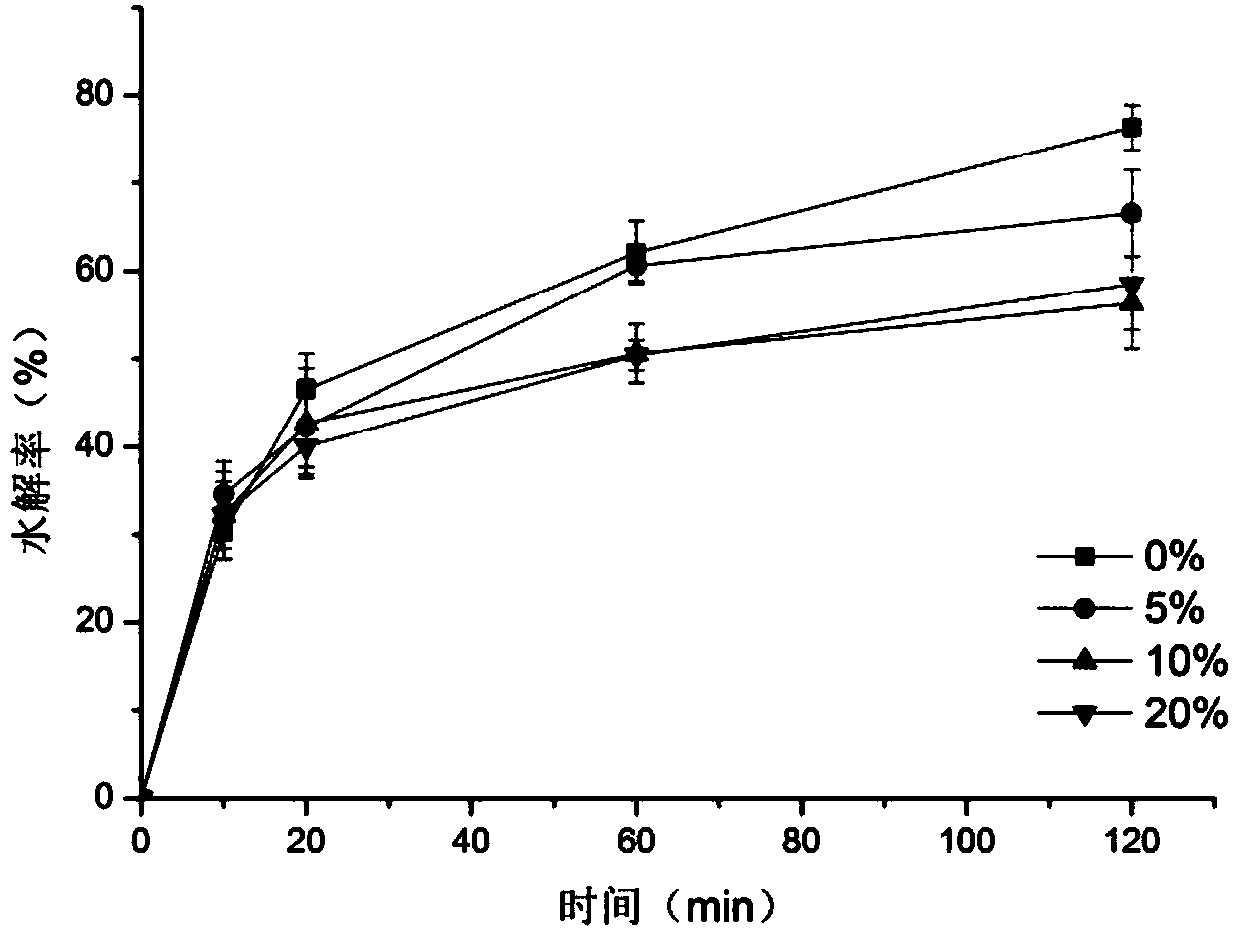

[0030] Accurately weigh 5g of corn starch into a 50mL centrifuge tube, add 0g, 0.25g, 0.5g, and 1g of whey protein powder (WPI) respectively, mix well, add deionized water at a ratio of 1:3 to the powder mass, and add a rotor. In a water bath at 95°C for 30 min. After the sample was taken out, it was allowed to cool naturally, and after standing for 5 days at 4 / 25°C with a time interval of 24h, the sample was dried at a low temperature of 35°C and passed through a 200-mesh sieve. The nutrient fragments of the complex were determined by double-enzyme method in vitro, and the resistant starch increased significantly with the increase of the protein ratio, and the content of resistant starch in the 10% WPI group was as high as 43.70%.

[0031] The starch-protein complex of this example was tested for starch digestibility by Englyst in vitro dual-enzyme method, as shown in Table 1.

[0032] Table 1 Contents of fast-digesting, slow-digesting and resistant starch in starch-protein ...

Embodiment 2

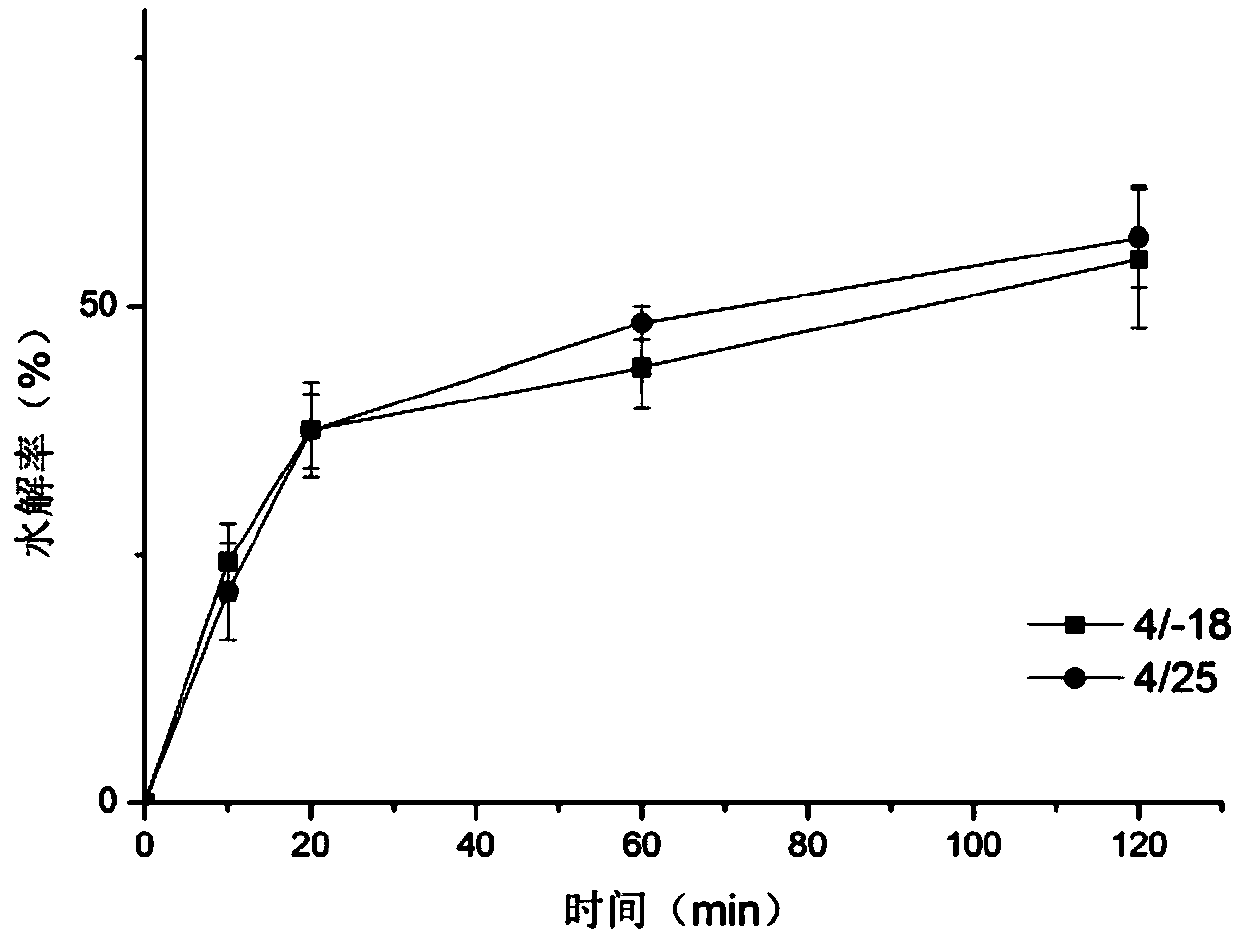

[0035] Accurately weigh 5g of cornstarch into a 50mL centrifuge tube, add 0.5g of whey protein powder, mix well, add deionized water at a ratio of 1:3 to the powder mass, add a rotor, and treat in a water bath at 95°C for 30 minutes. After the sample was taken out, it was allowed to cool naturally, and then placed at 4 / -18°C and 4 / 25°C for 5 days at an interval of 24 hours, then dried at a low temperature of 35°C and passed through a 200-mesh sieve.

[0036] The starch-protein complex of this example was measured by Englyst in vitro dual-enzyme method for starch digestibility, as shown in Table 2.

[0037] Table 2 Contents of fast-digesting, slow-digesting and resistant starch in starch-protein complexes prepared at different temperature changes

[0038]

Embodiment 3

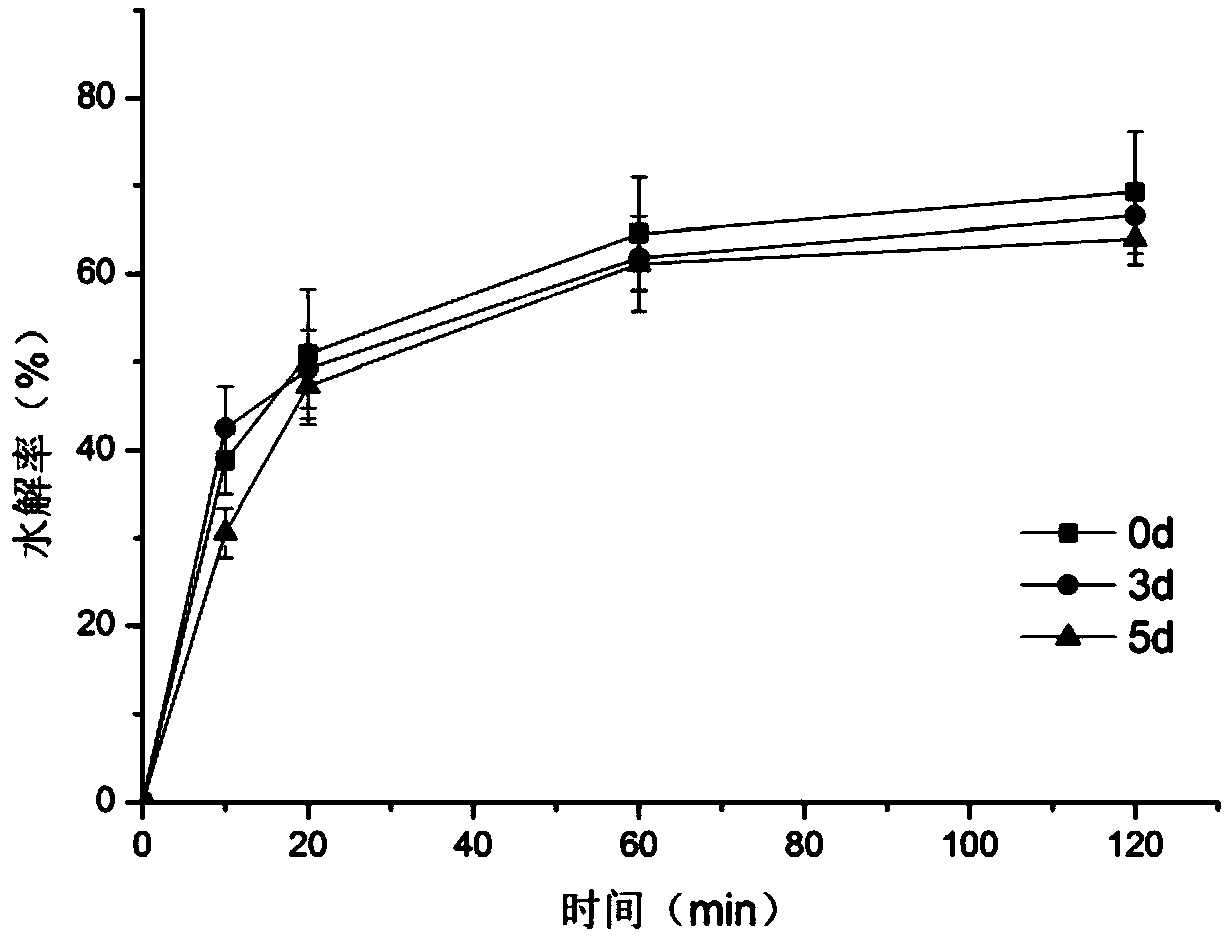

[0040] Accurately weigh 5g of cornstarch into a 50mL centrifuge tube, add 0.5g of whey protein powder, mix well, add deionized water at a ratio of 1:3 to the powder mass, add a rotor, and treat in a water bath at 95°C for 30 minutes. After taking out the sample, let it cool naturally, and place it at 4 / 25°C for 24h for 0d, 3d, and 5d, then dry the sample at a low temperature of 35°C and pass through a 200-mesh sieve. The digestibility of starch was determined by Englyst in vitro dual-enzyme method, and the digestion resistance of starch was significantly improved with the increase of temperature changing time.

[0041] The starch-protein complex of this example was measured by the Englyst in vitro dual-enzyme method for starch digestibility, as shown in Table 3.

[0042] Table 3 Contents of fast-digesting, slow-digesting and resistant starch in starch-protein complexes prepared at different temperature changes

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com