Novel low-temperature plasma sterilizer

A low-temperature plasma and sterilizer technology, applied in sanitary equipment for toilets, water supply devices, buildings, etc., can solve the problems of reducing plasma sterilization efficiency, unsuccessful plasma ignition, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

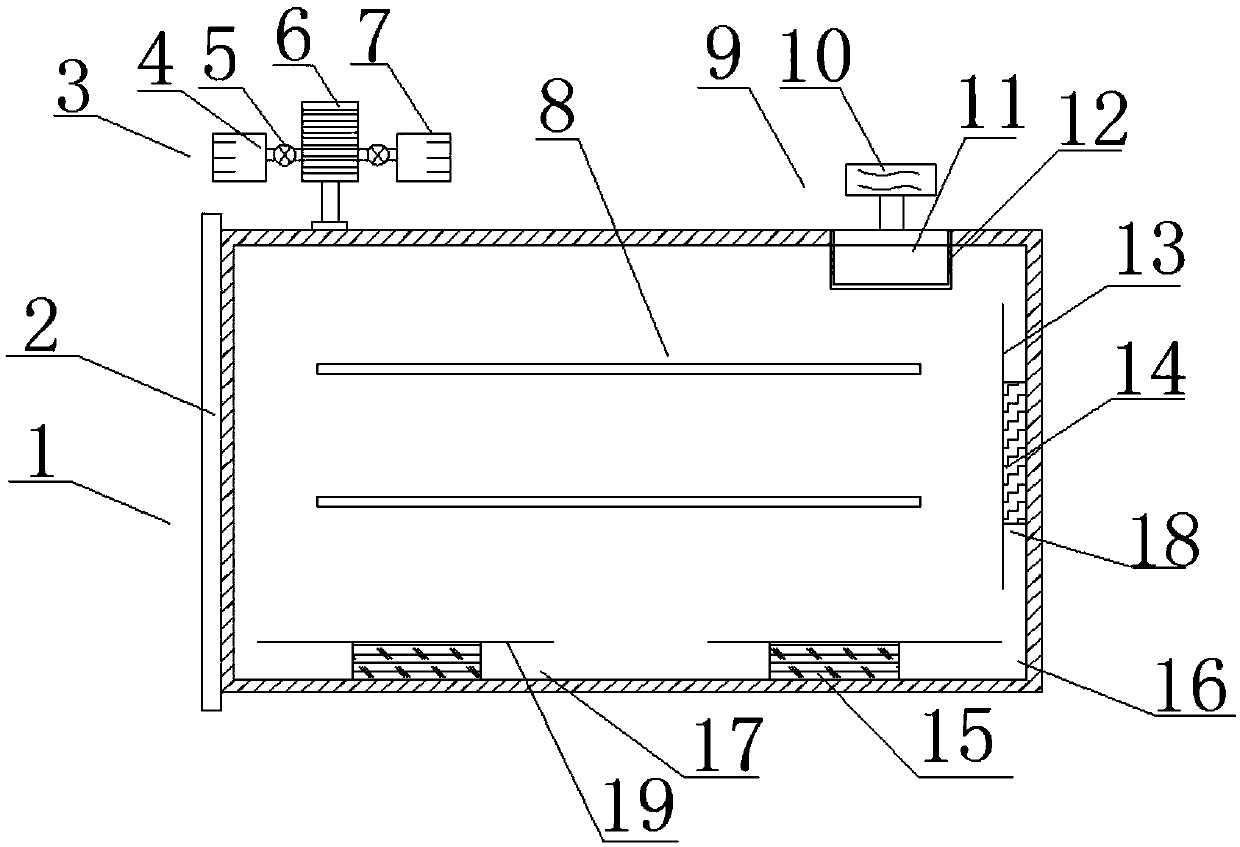

[0032] Such as figure 1 As shown, a new low-temperature plasma sterilizer includes a sterilizer body 1 and a front cover 2, and is characterized in that: the sterilizer body 1 includes a vacuum device 3, a liquid injection diffusion device 9 and a sterilization generating device 16 , the sterilization generating device 16 includes a DC sterilizing device 18 connected to a DC power source and a radio frequency sterilizing device 17 connected to an AC power source, the DC sterilizing device 18 includes a DC electrode 14 and a second electrode connected to the DC electrode 14 A metal mesh 13 , the radio frequency sterilizing device 17 includes a radio frequency electrode 15 and a second metal mesh 19 communicated with the radio frequency electrode 15 .

[0033] The working principle and process of this technical solution are as follows:

[0034] When using the present invention, open the front cover 2, wrap the medical instruments that need to be sterilized with non-woven fabric...

Embodiment 2

[0037] According to Example 1, such as figure 1 As shown, the vacuum device 3 includes an air inlet filter 4, an air outlet filter 7, and a vacuum pump 6 that is positioned between the air inlet filter 4 and the air outlet filter 7 and is connected through a trachea. The air exchange port located on the top surface of the sterilizer body 1 is connected. The setting of air inlet filter 4 can prevent impurity gas from entering in the sterilizer body 1 during air intake, and the setting of air outlet filter 7 can prevent that toxic gas is discharged into the air during air extraction.

Embodiment 3

[0039] According to embodiment 2, such as figure 1 As shown, ventilation valves 5 are provided between the air inlet filter 4 and the vacuum pump 6 and between the air outlet filter 7 and the vacuum pump 6 . The setting of the ventilation valve 5 helps to control the suction and intake of the vacuum pump 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com