Microwave heating adsorption and desorption tank and application thereof in environmental protection field of VOCs

A microwave heating and microwave heater technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of high operating energy consumption, large investment in process equipment, secondary pollution, etc., and achieve low operating costs, desorption and desorption. Good effect and low operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

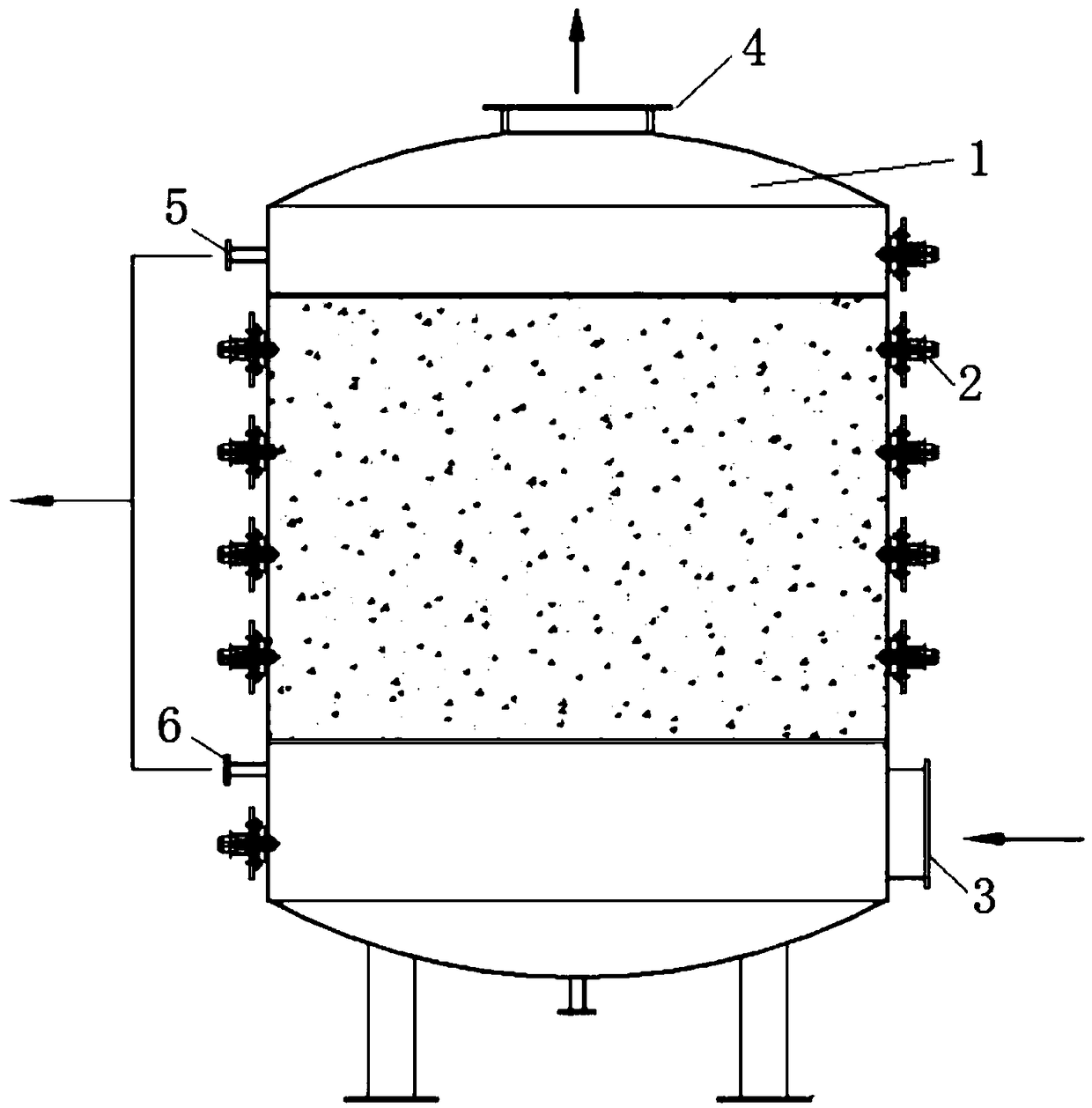

[0030] The invention provides a microwave heating adsorption-desorption tank and its application in the field of environmental protection Vocs treatment and its application. The microwave heating absorption-desorption tank includes a tank body 1, an adsorbent bed and a microwave heater 2;

[0031] The side wall of the tank body 1 is provided with an exhaust gas inlet 3 near the bottom, and the top is provided with an exhaust gas outlet 4. The side wall is provided with an upper steam outlet 5 and a lower steam outlet 6; an exhaust gas inlet 3, an exhaust gas outlet 4, and a steam upper outlet The outlet 5 and the lower steam outlet 6 are respectively provided with valves; the microwave heaters 2 are evenly distributed on the outer wall of the tank body 1 to form a microwave heating system;

[0032] There are several adsorbent beds inside the tank body 1; the exhaust gas inlet 3 is located upstream of the adsorbent bed, and the adsorption bed includes a skeleton with holes and a...

Embodiment 2

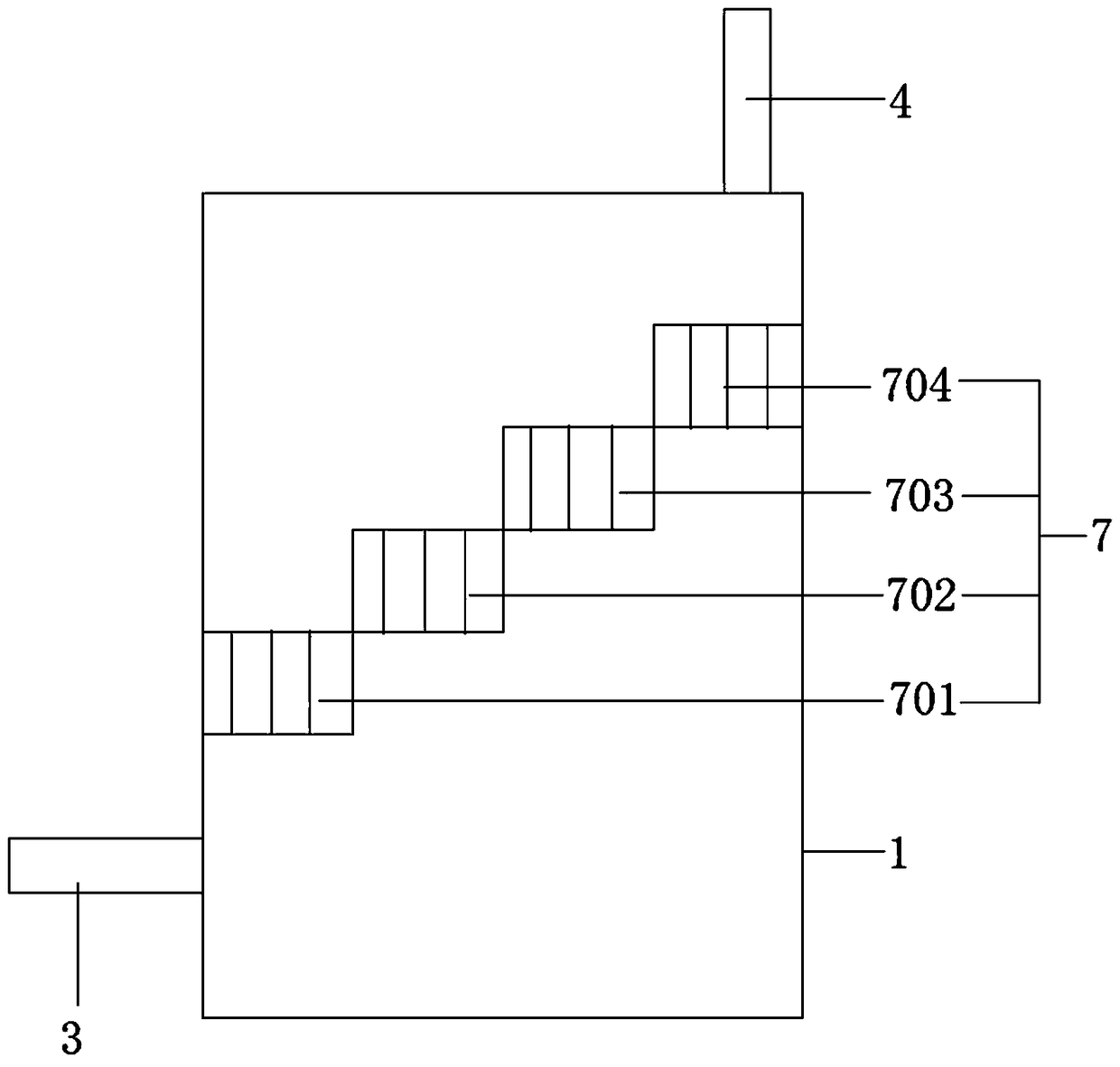

[0035] The invention provides a microwave heating adsorption-desorption tank and its application in the field of environmental protection Vocs treatment. The microwave heating absorption-desorption tank includes a tank body 1, an adsorbent bed and a microwave heater 2;

[0036] The side wall of the tank body 1 is provided with an exhaust gas inlet 3 near the bottom, and the top is provided with an exhaust gas outlet 4. The side wall is provided with an upper steam outlet 5 and a lower steam outlet 6; an exhaust gas inlet 3, an exhaust gas outlet 4, and a steam upper outlet The outlet 5 and the lower steam outlet 6 are respectively provided with valves; the microwave heaters 2 are evenly distributed on the outer wall of the tank body 1 to form a microwave heating system;

[0037] There are several adsorbent beds inside the tank body 1; the exhaust gas inlet 3 is located upstream of the adsorbent bed, and the adsorption bed includes a skeleton with holes and an adsorbent attached...

Embodiment 3

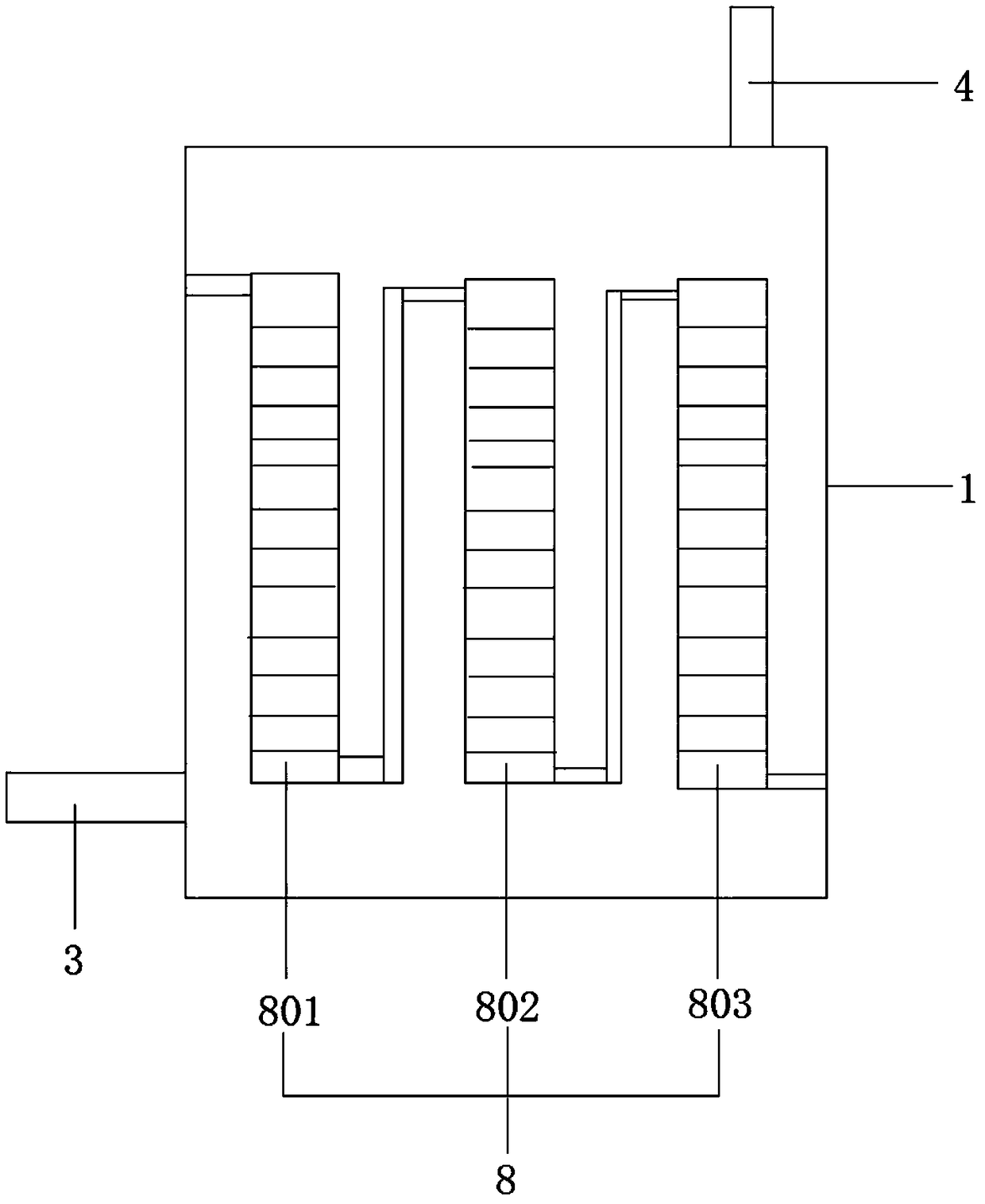

[0040] The invention provides a microwave heating adsorption-desorption tank and its application in the field of environmental protection Vocs treatment. The microwave heating absorption-desorption tank includes a tank body 1, an adsorbent bed and a microwave heater 2;

[0041] The side wall of the tank body 1 is provided with an exhaust gas inlet 3 near the bottom, and the top is provided with an exhaust gas outlet 4. The side wall is provided with an upper steam outlet 5 and a lower steam outlet 6; an exhaust gas inlet 3, an exhaust gas outlet 4, and a steam upper outlet The outlet 5 and the lower steam outlet 6 are respectively provided with valves; the microwave heaters 2 are evenly distributed on the outer wall of the tank body 1 to form a microwave heating system;

[0042] There are several adsorbent beds inside the tank body 1; the exhaust gas inlet 3 is located upstream of the adsorbent bed, and the adsorption bed includes a porous framework and an adsorbent attached to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com