Plasma cutting machine

A technology of a plasma cutting machine and a driving mechanism, which is applied to plasma welding equipment, welding equipment, metal processing equipment, etc., can solve the problems affecting the cutting quality and cutting accuracy of workpieces, increase maintenance and production costs, and reduce cutting efficiency, etc. The effect of cutting quality and cutting accuracy, simple structure, and reduction of production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

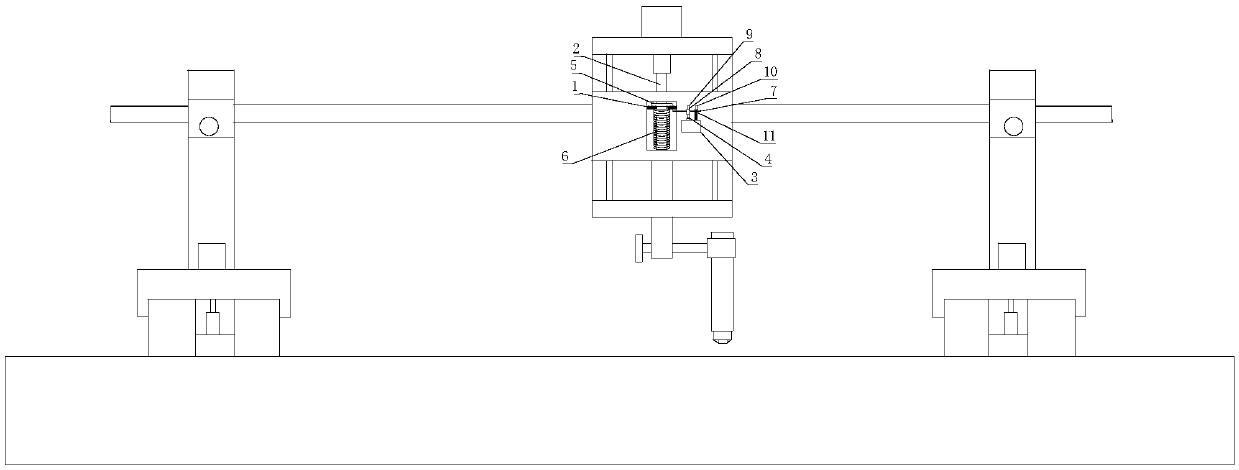

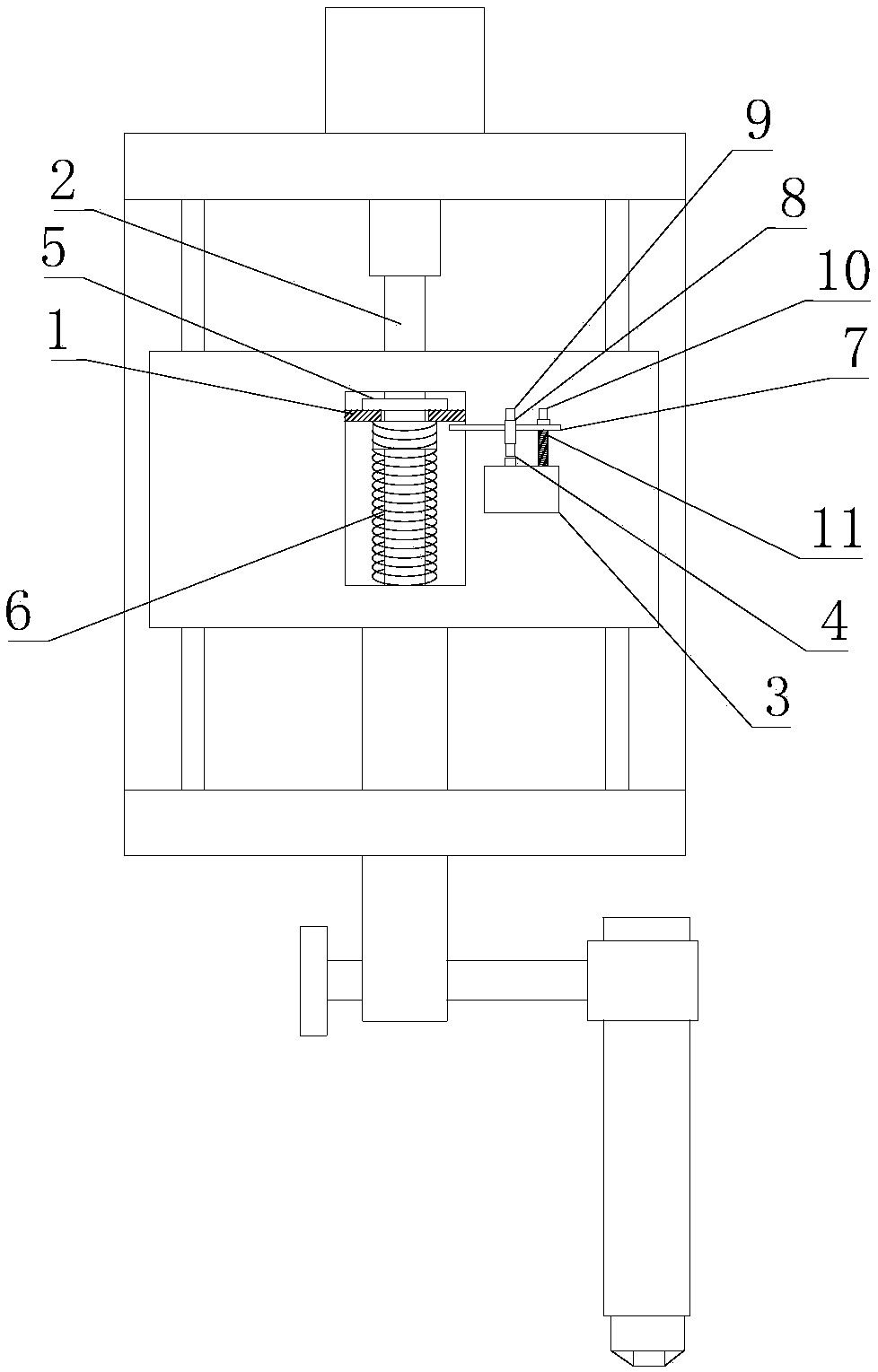

[0016] Such as Figure 1-2 as shown, figure 1 It is a schematic structural diagram of a plasma cutting machine proposed by the present invention; figure 2 It is a structural schematic diagram of a lifter proposed by the present invention.

[0017] refer to figure 1 , the present invention proposes a plasma cutting machine, including: a base, a first moving assembly, a second moving assembly, a lifter, an arc pressure sensor, a controller, and a cutting assembly, and a workbench for placing plates to be cut is arranged on the base , the first moving assembly is mounted on the base and can move in a first direction relative to the base, and the second moving assembly is installed on the first moving assembly and can move in a second direction perpendicular to the first direction relative to the first moving assembly movable, the lifter is fixed on the second moving component, the cutting component is installed on the lifter and can be driven up and down by the lifter, the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com