A kind of preparation method of ammonium fluorotitanate and ammonium fluorotitanate

A technology of ammonium fluorotitanate and ammonium fluoride, which is applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems of complex raw materials, complex preparation methods, and high cost, and achieves simple preparation methods and easy-to-obtain formula raw materials. , the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The present invention proposes a kind of preparation method of ammonium fluorotitanate, and this preparation method comprises the following steps:

[0020] mixing titanates with an organic solvent to obtain a first solution;

[0021] mixing ammonium fluoride and water to obtain a second solution;

[0022] mixing the first solution and the second solution to obtain a mixed solution;

[0023] Pour the mixed solution into the reactor for reaction to obtain mixed precipitates;

[0024] The mixed precipitates are cooled, filtered, washed, and dried to obtain ammonium fluotitanate.

[0025] The preparation method of ammonium fluorotitanate of the present invention adopts the first solution mixed with titanate and organic solvent, the second solution mixed with ammonium fluoride and water as raw materials, wherein, titanate is titanium source, ammonium fluoride A source of ammonia and a source of fluorine, the two are used as reactants, the organic solvent is used as the re...

Embodiment 1

[0042] The ethanol solution of tetrabutyl titanate is used as the first solution, and the aqueous solution of ammonium fluoride is used as the second solution, wherein the mass fraction of tetrabutyl titanate in the first solution is 1%, and the ammonium fluoride in the second solution is The mass concentration is 0.25g / mL. When preparing the mixed solution, add 550-650μL of 0.25g / mL ammonium fluoride aqueous solution for every 6mL of 1% tetrabutyl titanate solution, then add 4mL of absolute ethanol, and transfer it to the PTFE liner with a capacity of 15mL In a solvothermal reactor, seal it, react at 140°C for 12 hours, take out the reaction product, cool it down to room temperature naturally, filter, wash the precipitate with absolute ethanol, and dry it in a drying oven to obtain Pure phase ammonium fluorotitanate powder.

[0043] It can be known from weighing calculation that the yield of ammonium fluorotitanate obtained in this embodiment is 61%.

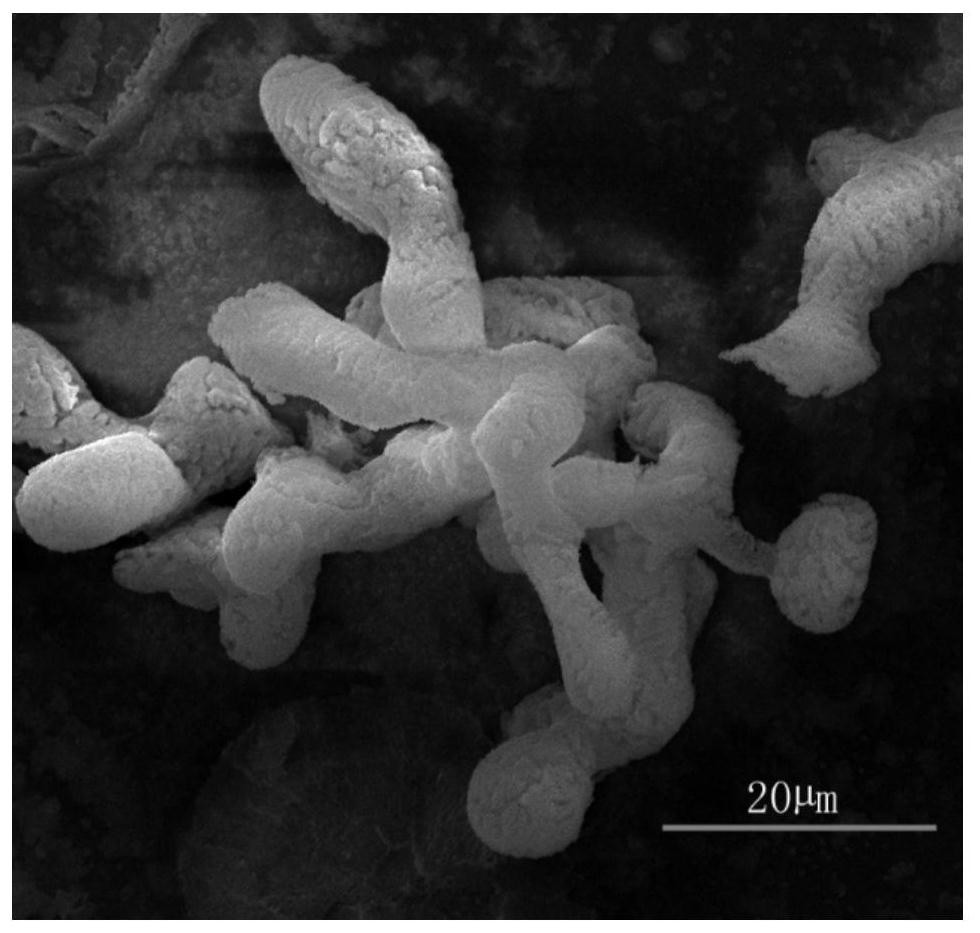

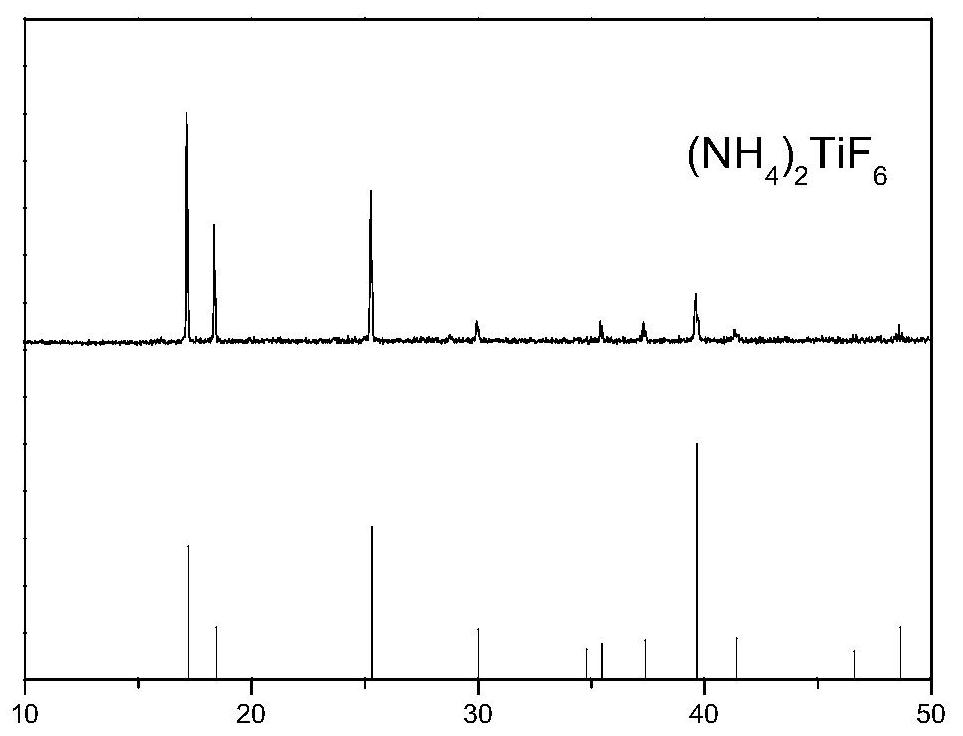

[0044] The prepared pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com