Method for purifying polyoxymethylene dimethyl ether

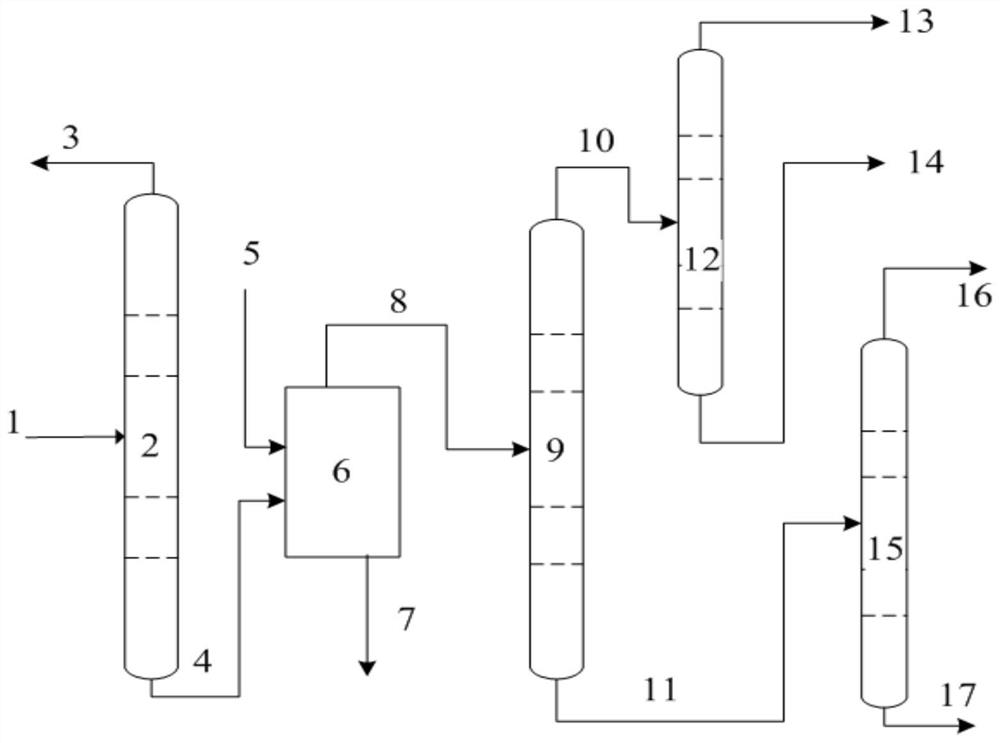

A technology of polyoxymethylene dimethyl ether and methanol, which is applied in the reaction mixture containing polyoxymethylene dimethyl ether to prepare high-purity PODE3-4 products and PODE3-5 products, which can solve the problem of unfavorable expansion of production and the impact of polyoxymethylene dimethyl ether. Problems such as continuous and stable operation and long processing time of oxydimethyl ether separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

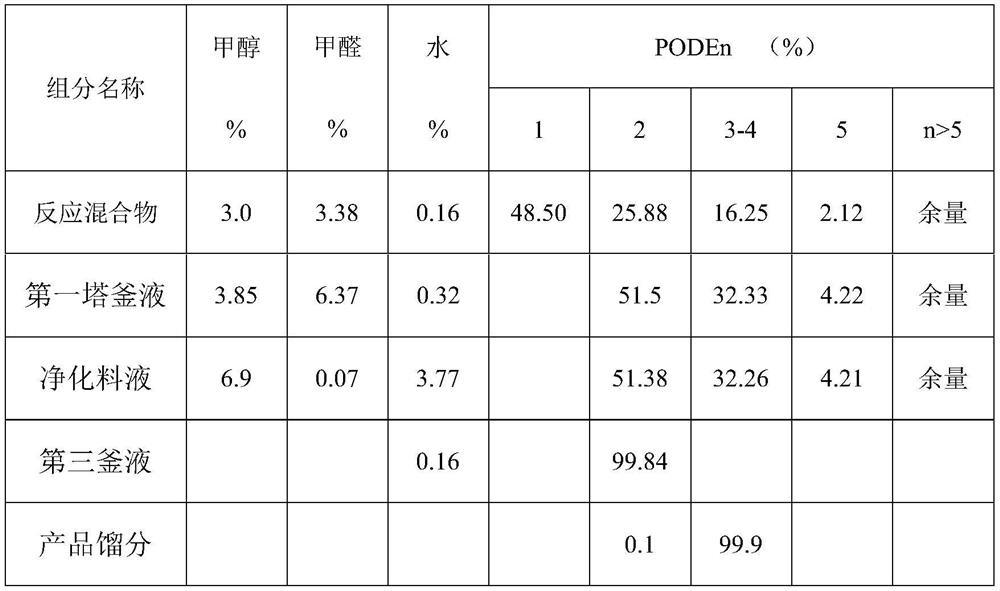

Embodiment 1

[0041] The reaction mixture obtained by catalytic reaction using paraformaldehyde and methylal as raw materials is firstly rectified by the first rectification tower under normal pressure to remove the first fraction, and the first tower still liquid with a temperature of 105°C is obtained. The first tower still liquid enters the purification tank to contact and react with the chemical treatment liquid; the chemical treatment liquid is a 40% alkali aqueous solution configured with a mass ratio of 1:1 NaOH and KOH solid mixture and water; the dosage is 10% of the first tower still liquid %. The reaction temperature of the purification tank is 90°C, the stirring reaction time is 20min, and then the chemical treatment liquid is separated to obtain PODE containing 2-5 Purified feed liquid. The purified feed liquid enters the second rectification tower and is rectified under normal pressure. The temperature of the bottom of the tower is 155° C., and the second fraction containing ...

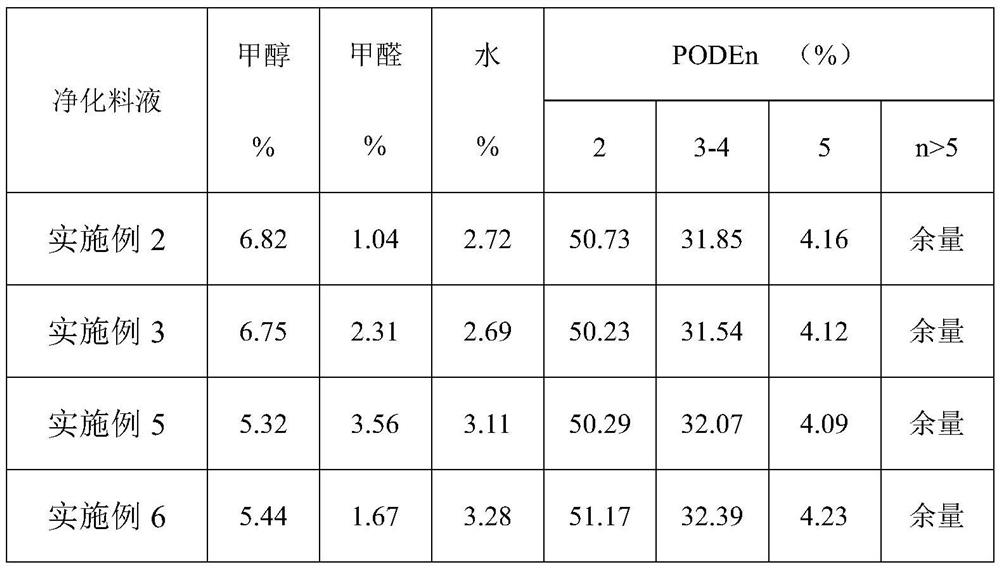

Embodiment 2

[0045] The reaction mixture obtained by catalytic reaction using paraformaldehyde and methylal as raw materials is firstly rectified by the first rectification tower under normal pressure to remove the first fraction, and the first tower still liquid with a temperature of 105°C is obtained. The first tower still liquid enters the purification tank and reacts with the chemical treatment liquid; the used chemical treatment liquid is a NaOH aqueous solution with a concentration of 40%, and the consumption is 10% of the first tower still liquid. The reaction temperature of the purification tank is 90°C, the stirring reaction time is 20min, and then the chemical treatment liquid is separated to obtain PODE containing 2-5 Purified feed liquid. The purified feed liquid enters the second rectification tower and is rectified under normal pressure. As a result, it is found that a white solid is precipitated from the top of the second rectification tower after about 4 hours. Component a...

Embodiment 3

[0047] The reaction mixture obtained by catalytic reaction using paraformaldehyde and methylal as raw materials is firstly rectified by the first rectification tower under normal pressure to remove the first fraction, and the first tower still liquid with a temperature of 105°C is obtained. The first tower still liquid enters the purification tank and reacts with the chemical treatment liquid; the used chemical treatment liquid is a KOH aqueous solution with a concentration of 40%, and the consumption is 10% of the first tower still liquid. The reaction temperature of the purification tank is 90°C, the stirring reaction time is 20min, and then the chemical treatment liquid is separated to obtain PODE containing 2-5 Purified feed liquid. The purified feed liquid enters the second rectification tower and is rectified under normal pressure. As a result, it is found that a white solid is precipitated from the top of the second rectification tower after about 3 hours. Component an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com