Time-delayed aliphatic polyurethane topcoat

An aliphatic polyurethane, aliphatic technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of inability to use, inability to guarantee coating quality, inability to guarantee the use of coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

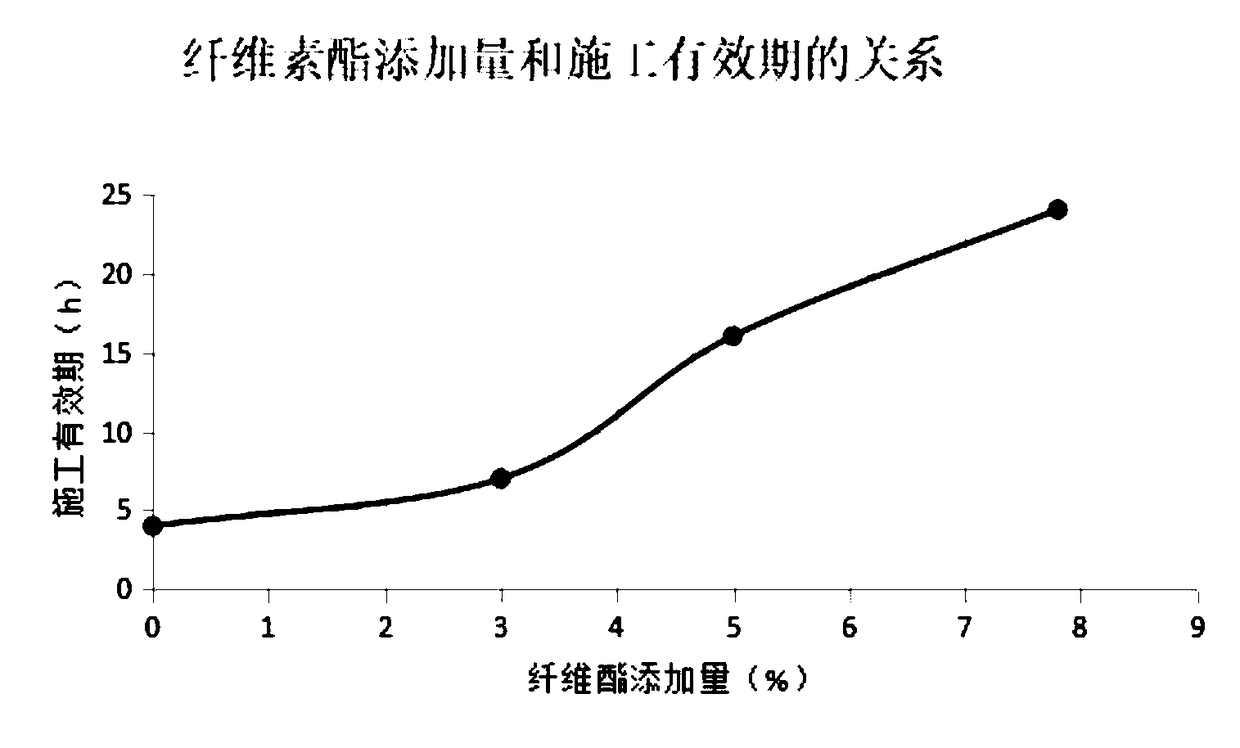

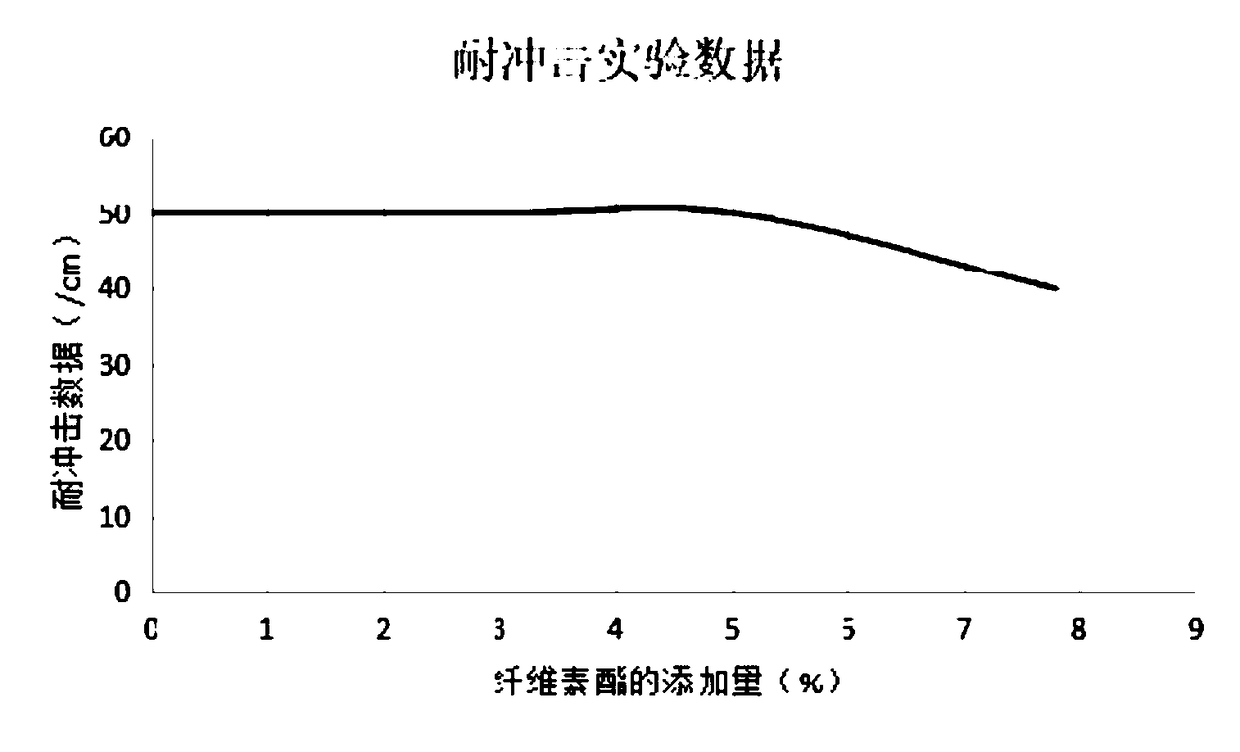

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

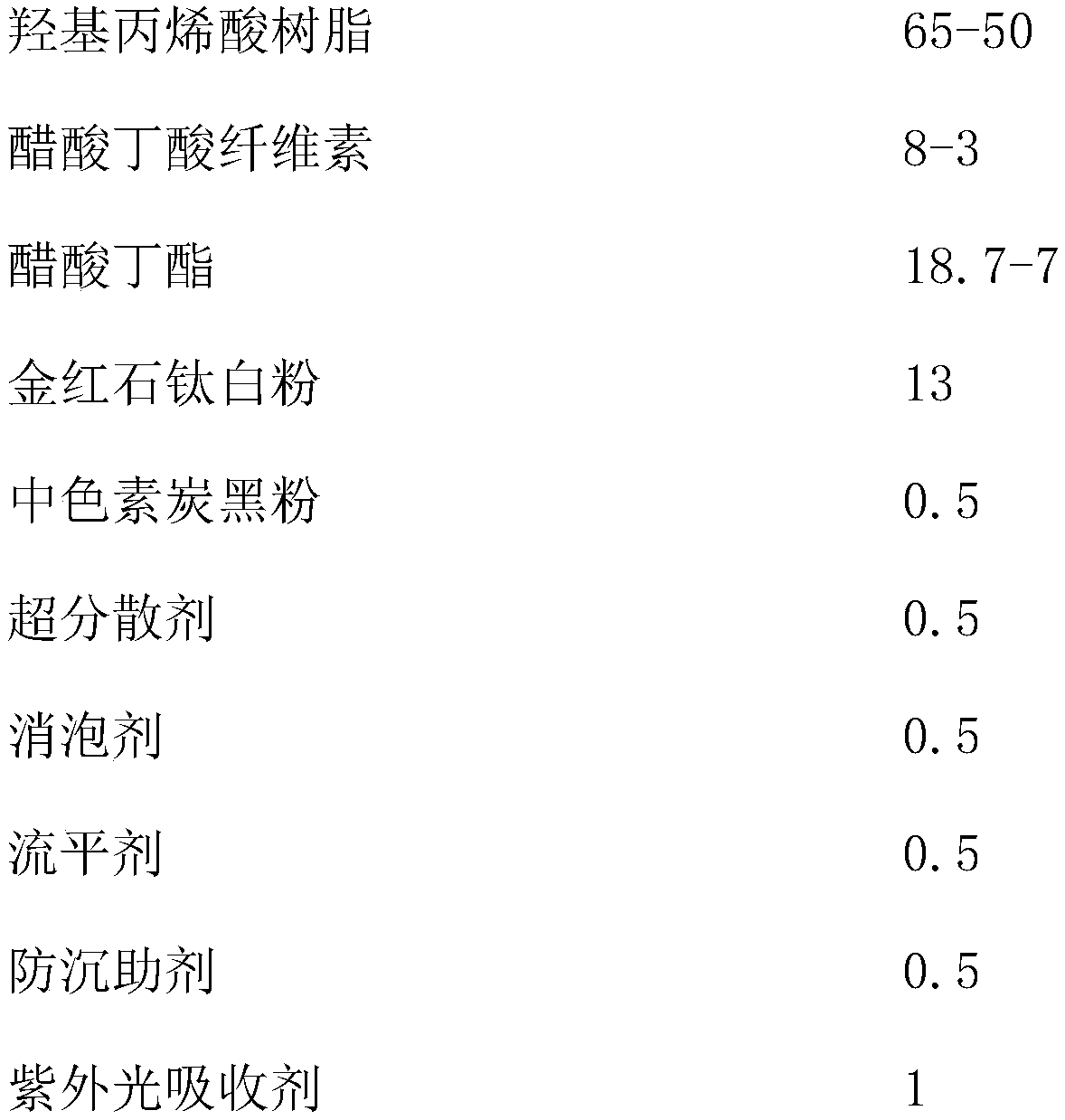

[0037] The composition of time-delay type aliphatic polyurethane topcoat by mass parts is shown in Table 1:

[0038] According to the mass ratio of 30:70, add cellulose acetate butyrate into butyl acetate, stir while adding, until completely dissolved, and obtain 30% cellulose acetate butyrate solution.

[0039] Table 1

[0040]

[0041] The preparation method of above-mentioned delay type aliphatic polyurethane topcoat comprises following processing steps:

[0042] (1) Pre-dissolve cellulose acetate butyrate into a 30% uniform liquid with a solvent for subsequent use.

[0043] (2) Add a small amount of paint thinner into the mixing tank, pour resin, add DISPERBYK110 dispersant 0.5%, disperse at high speed until a uniform liquid is formed, add pigment powder and continue stirring at high speed, then grind with a horizontal sand mill, After grinding to fineness <20, fine-tune the color, add leveling agent, defoamer, anti-settling agent, ultraviolet light absorber, stir eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com