Cable sealing module and preparation method thereof

A technology of cable sealing and vinyl end sealing, which is applied in the direction of cable entry sealing devices, etc., can solve the problems of cumbersome production methods, short service life of materials, and difficult replacement, and achieve excellent sealing and radiation protection performance, improve flame retardancy, The effect of improving radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

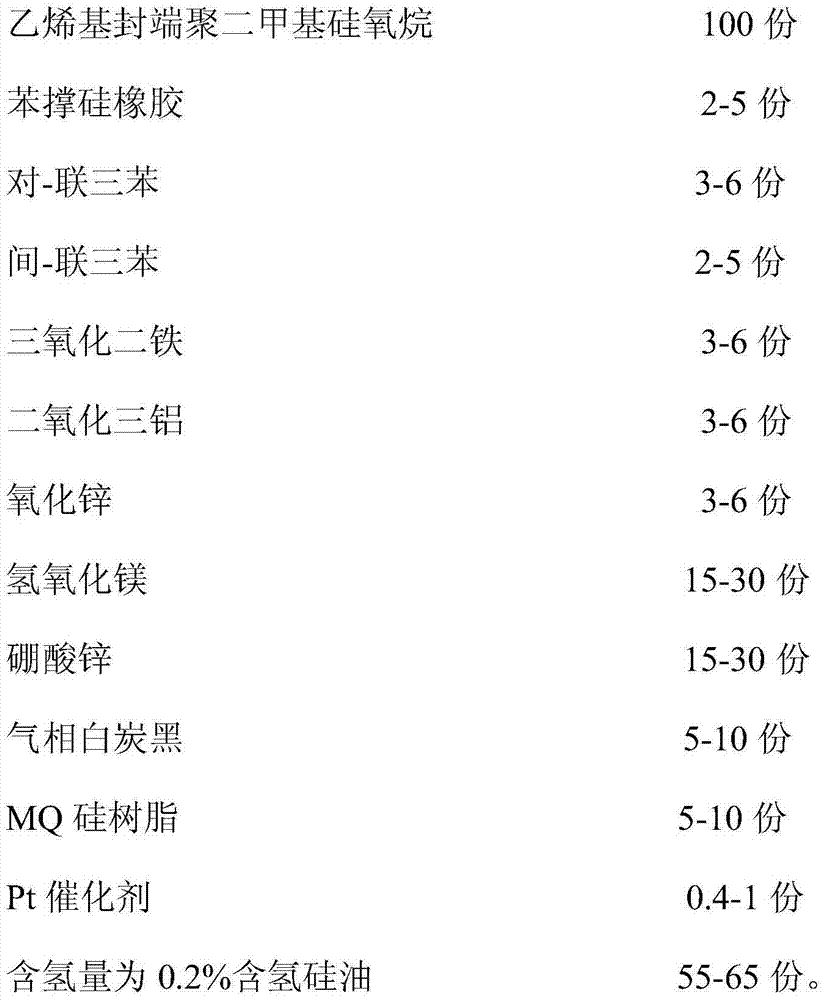

Method used

Image

Examples

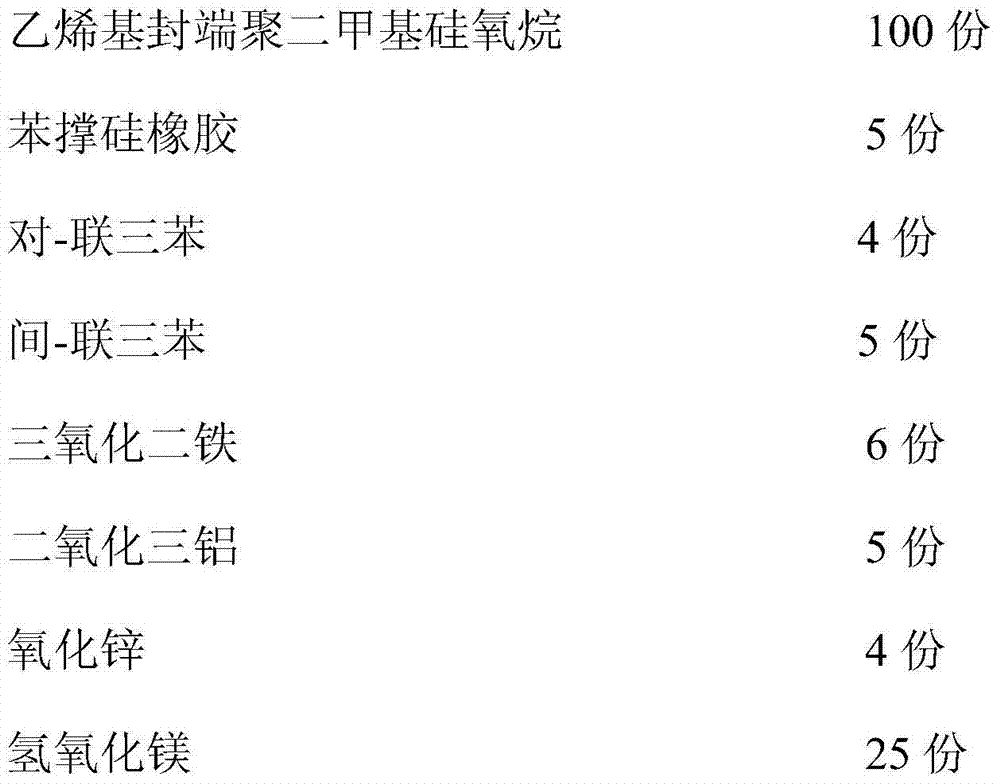

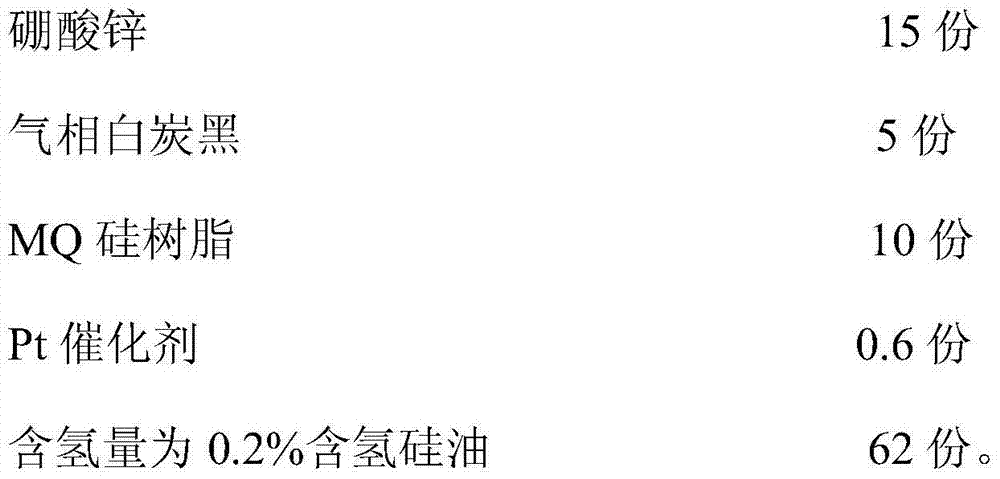

Embodiment 1

[0016] A method for preparing a cable sealing module, the preparation steps are as follows: first, 100 parts of vinyl-terminated polydimethylsiloxane and 5 parts of phenylene silicone rubber are added to a multifunctional dispersing mixer, and mixed at 20 ° C 20min, then add 4 parts of p-terphenyl, 5 parts of m-terphenyl, 6 parts of ferric oxide, 5 parts of aluminum dioxide, 4 parts of zinc oxide, 25 parts of magnesium hydroxide, 15 parts of zinc borate, 5 parts of fumed silica, 10 parts of MQ silicone resin, stir and mix for 60 minutes, then add 0.6 parts of Pt catalyst, stir and disperse for 40 minutes, finally add 62 parts of hydrogen-containing silicone oil with a hydrogen content of 0.2%, stir and mix for 10 minutes, pour into In the mold, let it stand for degassing and curing for 40 minutes in an environment with a temperature of 25°C and a relative humidity of 60%. After demolding, the semi-finished products of each component are obtained, and then assembled to obtain a ...

Embodiment 2

[0018] A method for preparing a cable sealing module, the preparation steps are as follows: first, 100 parts of vinyl-terminated polydimethylsiloxane and 2 parts of phenylene silicone rubber are added to a multifunctional dispersing mixer, and mixed at 25 ° C 30min, then add 3 parts of p-terphenyl, 2 parts of m-terphenyl, 3 parts of ferric oxide, 6 parts of aluminum dioxide, 3 parts of zinc oxide, 15 parts of magnesium hydroxide, 20 parts of zinc borate, 10 parts of fumed silica, 7 parts of MQ silicone resin, stirred and mixed for 50 minutes, then added 1 part of Pt catalyst, stirred and dispersed for 30 minutes, and finally added 55 parts of hydrogen-containing silicone oil with a hydrogen content of 0.2%, stirred and mixed for 5 minutes, poured into In the mold, let it stand for degassing and curing for 20 minutes in an environment with a temperature of 25°C and a relative humidity of 60%. After demolding, the semi-finished products of each component are obtained, and then co...

Embodiment 3

[0020] A method for preparing a cable sealing module, the preparation steps are as follows: first, 100 parts of vinyl-terminated polydimethylsiloxane and 5 parts of phenylene silicone rubber are added to a multifunctional dispersing mixer, and mixed at 23 ° C 25min, then add 6 parts of p-terphenyl, 3 parts of m-terphenyl, 5 parts of ferric oxide, 3 parts of aluminum dioxide, 6 parts of zinc oxide, 30 parts of magnesium hydroxide, 15 parts of zinc borate, 8 parts of fumed silica, 5 parts of MQ silicone resin, stirred and mixed for 40 minutes, then added 0.4 parts of Pt catalyst, stirred and dispersed for 35 minutes, and finally added 65 parts of hydrogen-containing silicone oil with a hydrogen content of 0.2%, stirred and mixed for 15 minutes, poured into In the mold, let it stand for degassing and curing for 40 minutes in an environment with a temperature of 25°C and a relative humidity of 60%. After demolding, the semi-finished products of each component are obtained, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com