High-sealing-performance waterproof anti-aging cable sealing element

An anti-aging cable and high-sealing technology, which is applied in the direction of electrical components, etc., can solve the problems of cumbersome production methods, easy aging of cable seals, and short circuits, etc., achieve excellent sealing and radiation protection performance, and improve sealing performance. Good antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

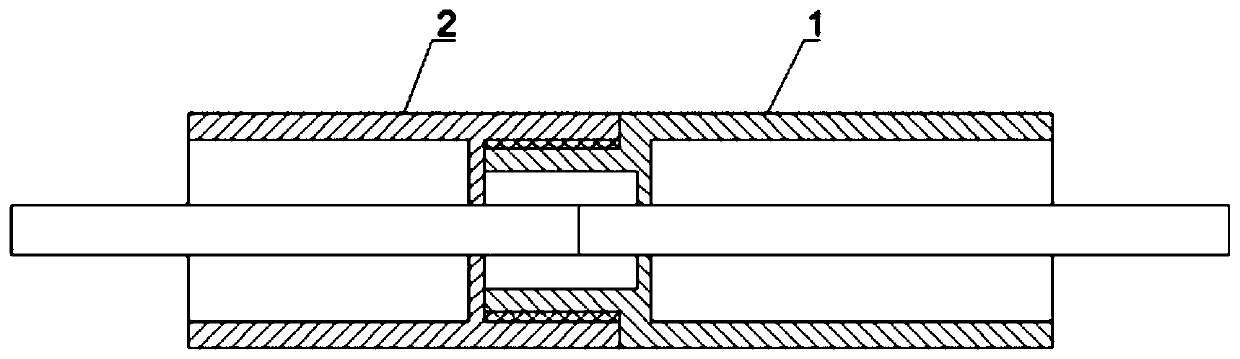

[0069] Such as figure 1 The shown high-tightness, waterproof and anti-aging cable seal is characterized by: comprising: a first sealing tube 1 and a second sealing tube 2; the axis of the first sealing tube 1 overlaps the axis of the second sealing tube 2; The first sealed tube 1 and the second sealed tube 2 are in contact and locked; the first sealed tube 1 is composed of a first front end and a first rear end; the second sealed tube 2 is composed of a second front end and a second rear end. End set; the second front end is provided with a protruding portion, a limiting cavity is formed between the protruding portion and the second front end, and the limiting cavity extends along the axial direction of the second connecting tube; A sealant is provided in the limiting cavity; the first rear end is inserted into the limiting cavity; the first rear end is connected to the second front end by interference fit through the sealant;

[0070] The base material used for injection moldin...

Embodiment 2

[0116] Such as figure 1 The shown high-tightness, waterproof and anti-aging cable seal is characterized by: comprising: a first sealing tube 1 and a second sealing tube 2; the axis of the first sealing tube 1 and the axis of the second sealing tube 2 overlap; The first sealed tube 1 and the second sealed tube 2 are in contact and locked; the first sealed tube 1 is composed of a first front end and a first rear end; the second sealed tube 2 is composed of a second front end and a second rear end. End set; the second front end is provided with a protruding portion, a limiting cavity is formed between the protruding portion and the second front end, and the limiting cavity extends along the axial direction of the second connecting pipe; A sealant is provided in the limiting cavity; the first rear end is inserted into the limiting cavity; the first rear end is connected to the second front end by interference fit through the sealant;

[0117] The base material used for injection mol...

Embodiment 3

[0163] Such as figure 1 The shown high-tightness, waterproof and anti-aging cable seal is characterized by: comprising: a first sealing tube 1 and a second sealing tube 2; the axis of the first sealing tube 1 and the axis of the second sealing tube 2 overlap; The first sealed tube 1 and the second sealed tube 2 are in contact and locked; the first sealed tube 1 is composed of a first front end and a first rear end; the second sealed tube 2 is composed of a second front end and a second rear end. End set; the second front end is provided with a protruding portion, a limiting cavity is formed between the protruding portion and the second front end, and the limiting cavity extends along the axial direction of the second connecting pipe; A sealant is provided in the limiting cavity; the first rear end is inserted into the limiting cavity; the first rear end is connected to the second front end by interference fit through the sealant;

[0164] The base material used for injection mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com