Furniture edge sealing glue and preparation method thereof

A technology for edge sealing glue and furniture, which is applied in the directions of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of high cost of edge sealing glue and poor hardness of edge sealing hot melt adhesive, and save processing costs. , The effect of good temperature resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

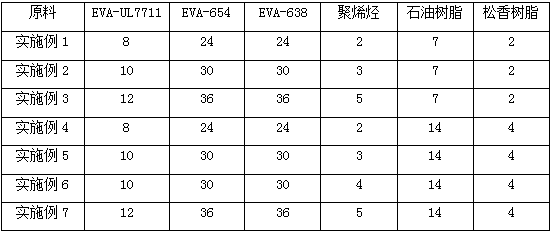

[0021] The preferred formula composition and mass parts thereof of the present embodiment are as shown in Table 1 below:

[0022]

[0023] testing method

[0024] The colloid obtained by the proportioning of raw materials in this embodiment 1-7 is detected using the following method:

[0025] 1. The heat resistance test is carried out according to the relevant clauses of HG / T 3698-2002 EVA hot melt adhesive.

[0026] 2. Adhesiveness, apply the colloid on the outside of the wooden furniture, roll it twice with a 2KG roller, and test the peeling strength of the glue after taking it out.

[0027] 3. Weather resistance, apply the colloid on the outside of wooden furniture, and pass the Shore hardness tester after 1 hour.

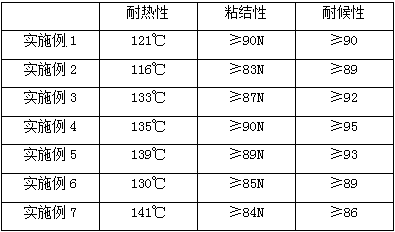

[0028] The colloid performance parameter that embodiment 1-7 makes is as shown in table 2 below:

[0029]

[0030] Through the test of examples 1-7, it can be seen that the colloid obtained in the proportion of example 5 has better heat resistance, stro...

Embodiment 8-13

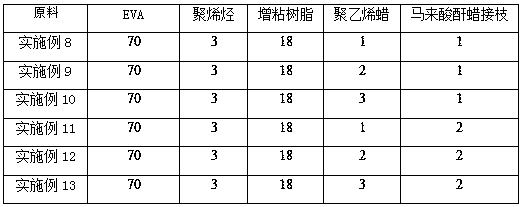

[0032] The preferred formula that above-mentioned experiment obtains adds polyethylene wax and maleic anhydride wax to graft, and its specific mass parts are as shown in 3:

[0033]

[0034] testing method

[0035] The colloid obtained by the ratio of raw materials in this embodiment 8-13 is detected using the following method:

[0036] 1. Adhesiveness, apply the colloid on the outside of the wooden furniture, roll it twice with a 2KG roller, and test the peel strength of the glue after taking it out.

[0037] The colloid performance parameter that embodiment 8-13 is made is as shown in table 4 below:

[0038]

[0039] Based on the tests in the above examples, the raw material of this furniture edge banding glue is preferably prepared from the following ingredients in proportion by mass: EVA-UL7711, 10 parts; EVA-654, 30 parts; EVA-638, 30 parts; polyolefin, 3 parts; Tackifying resin, 18 parts; polyethylene wax, 2 parts; maleic anhydride wax grafted, 2 parts. 18 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com