Self-crushing concrete based on magnetocaloric excitation, preparation method and application thereof

A self-shredding, concrete technology, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of normal life interference, noise and dust, and low construction efficiency of surrounding residents, so as to reduce construction difficulty, save time, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

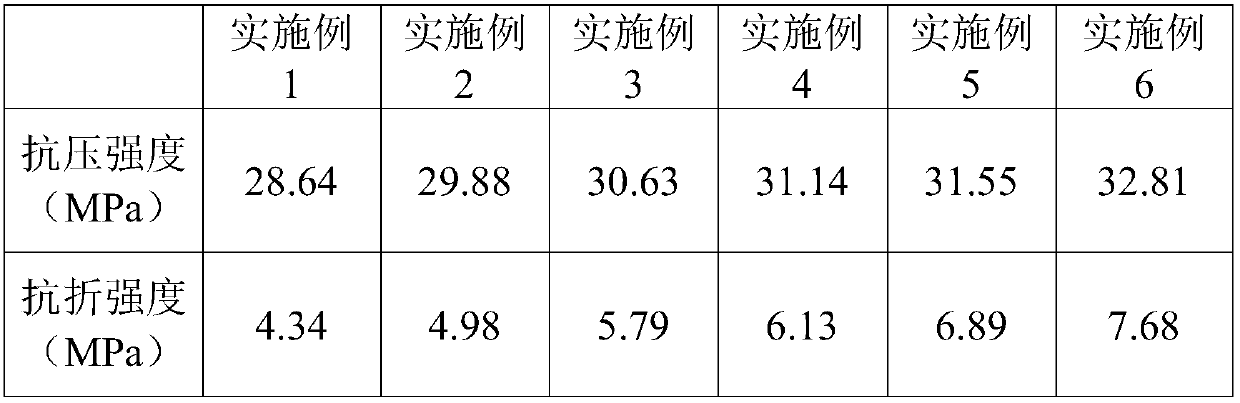

Examples

Embodiment 1

[0017] A self-shattering concrete based on magneto-thermal excitation, including the following components according to weight ratio: 250 parts of sulfur, 100 parts of Portland cement, 150 parts of fine aggregate, 360 parts of coarse aggregate, 12 parts of paraffin, 35 parts of magnetic powder parts, 22 parts of mineral fillers. The measured density after mixing the aforementioned components is 2050kg / m 3 .

[0018] Among them, the coarse aggregate is perlite particles with a diameter of 10 mm to 40 mm without high temperature roasting, and the fine aggregate is perlite sand with a diameter of 0.1 mm to 5 mm without high temperature roasting. The magnetic powder is manganese zinc ferrite powder, and the mineral filler is fly ash.

[0019] The above-mentioned preparation method of self-shattering concrete based on magneto-thermal excitation comprises the following steps:

[0020] Step 1: Weigh according to the above group distribution ratio;

[0021] Step 2: Stir the coarse ...

Embodiment 2

[0026] A self-shattering concrete based on magneto-thermal excitation, comprising the following components by weight ratio: 270 parts of sulfur, 110 parts of Portland cement, 160 parts of fine aggregate, 380 parts of coarse aggregate, 12 parts of paraffin, 40 parts of magnetic powder parts, 22 parts of mineral fillers. The measured density after mixing the aforementioned components is 2150kg / m 3 .

[0027] Among them, the coarse aggregate is perlite particles with a diameter of 10 mm to 40 mm without high temperature roasting, and the fine aggregate is perlite sand with a diameter of 0.1 mm to 5 mm without high temperature roasting. Magnetic powder is Fe 3 o 4 Powder, the mineral filler is silica powder.

[0028] The preparation method and application of the self-crushing concrete based on magnetothermal excitation are the same as those in Example 1.

Embodiment 3

[0030] A self-shattering concrete based on magneto-thermal excitation, including the following components according to weight ratio: 290 parts of sulfur, 120 parts of Portland cement, 170 parts of fine aggregate, 400 parts of coarse aggregate, 15 parts of paraffin, 45 parts of magnetic powder parts, 25 parts of mineral fillers. The measured density after mixing the aforementioned components is 2250kg / m 3 .

[0031] Among them, the coarse aggregate is perlite particles with a diameter of 10 mm to 40 mm without high temperature roasting, and the fine aggregate is perlite sand with a diameter of 0.1 mm to 5 mm without high temperature roasting. The magnetic powder is manganese zinc ferrite powder, and the mineral filler is fly ash.

[0032] The preparation method and application of the self-crushing concrete based on magnetothermal excitation are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com