Premixing apparatus for producing vulcanization capsule

A vulcanized bladder and pre-mixing technology, applied in the field of vulcanized bladder production equipment, can solve the problems of long time required and poor mixing effect, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

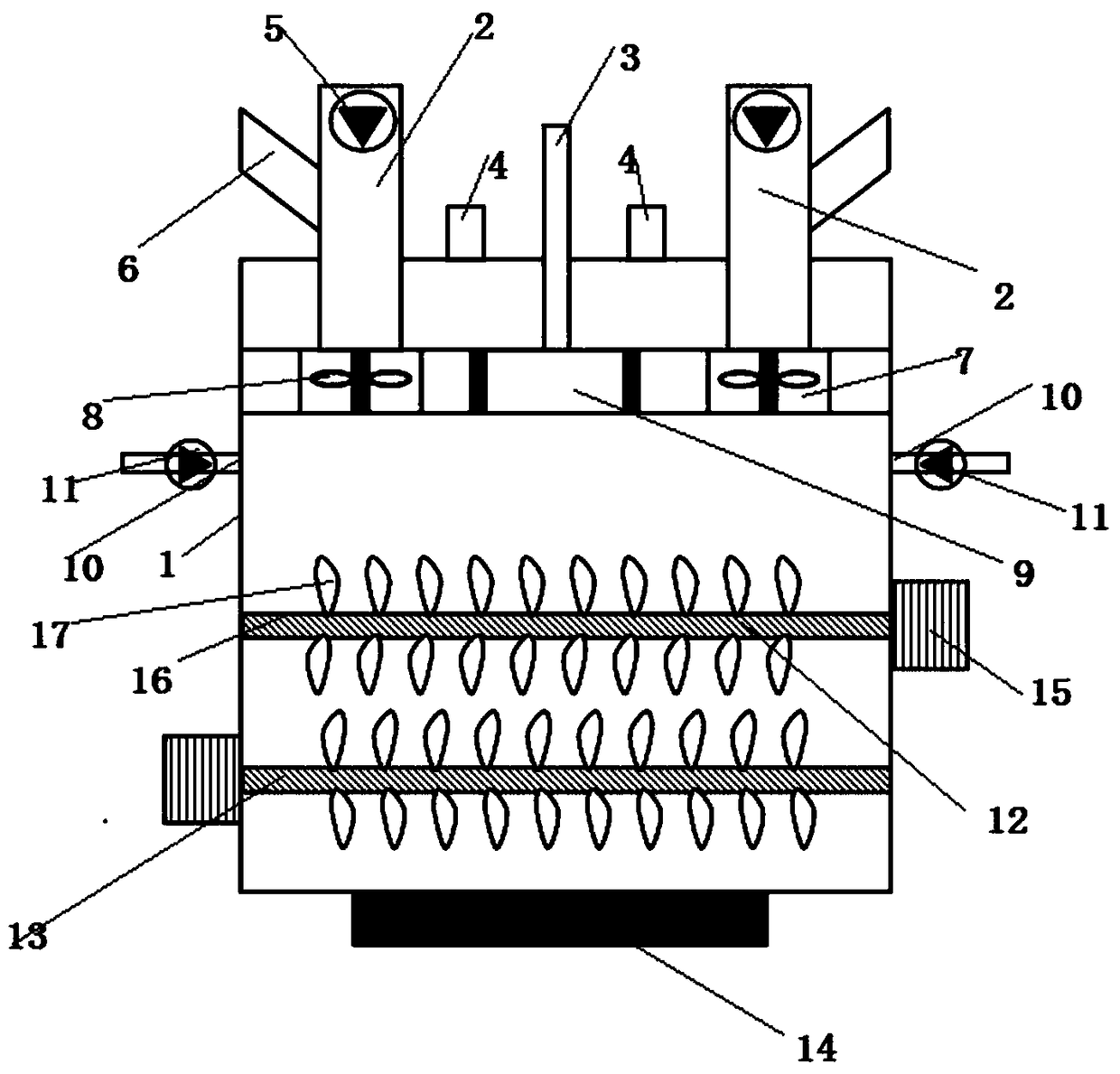

[0017] see figure 1 , a premixing device for producing vulcanization bladders, comprising a premixing chamber 1;

[0018] The top of the premixing chamber 1 is provided with a powder feed pipe 2, a liquid feed pipe 3 and an air outlet 4, the top of the powder feed pipe 2 is provided with an air intake pump 5, and the side wall of the powder feed pipe 2 is provided with a feed Branch pipe 6, the lower end of the powder feeding pipe 2 is connected to the powder shearing chamber 7 inside the premixing chamber 1, and a horizontal rotating blade 8 is arranged in the powder shearing chamber 7; the liquid feeding The lower end of the tube 3 is connected to the ultrasonic mixing chamber 9 in the premixing chamber 1, and an ultrasonic generating device is arranged in the ultrasonic mixing chamber 9; an opening is arranged at the bottom of the powder material shearing chamber 7 and the ultrasonic mixing chamber 9; The cutting chamber 7 and the ultrasonic mixing chamber 9 are set on the...

Embodiment 2

[0020] see figure 1 , as an improvement of the present invention, the stirring paddles 17 of the first stirring part 12 and the second stirring part 13 are vertically arranged alternately. Mix better.

Embodiment 3

[0022] see figure 1 , as an improvement of the present invention, the feed branch pipe 6 is arranged obliquely upward. Easy to add solid powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com