High-heat and strength hot work die steel and preparation method thereof

A technology of hot-working die steel and die steel, which is applied in the field of die steel, can solve problems such as insufficient high-temperature strength and hardness, and achieve good stability, high strength, and fine and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

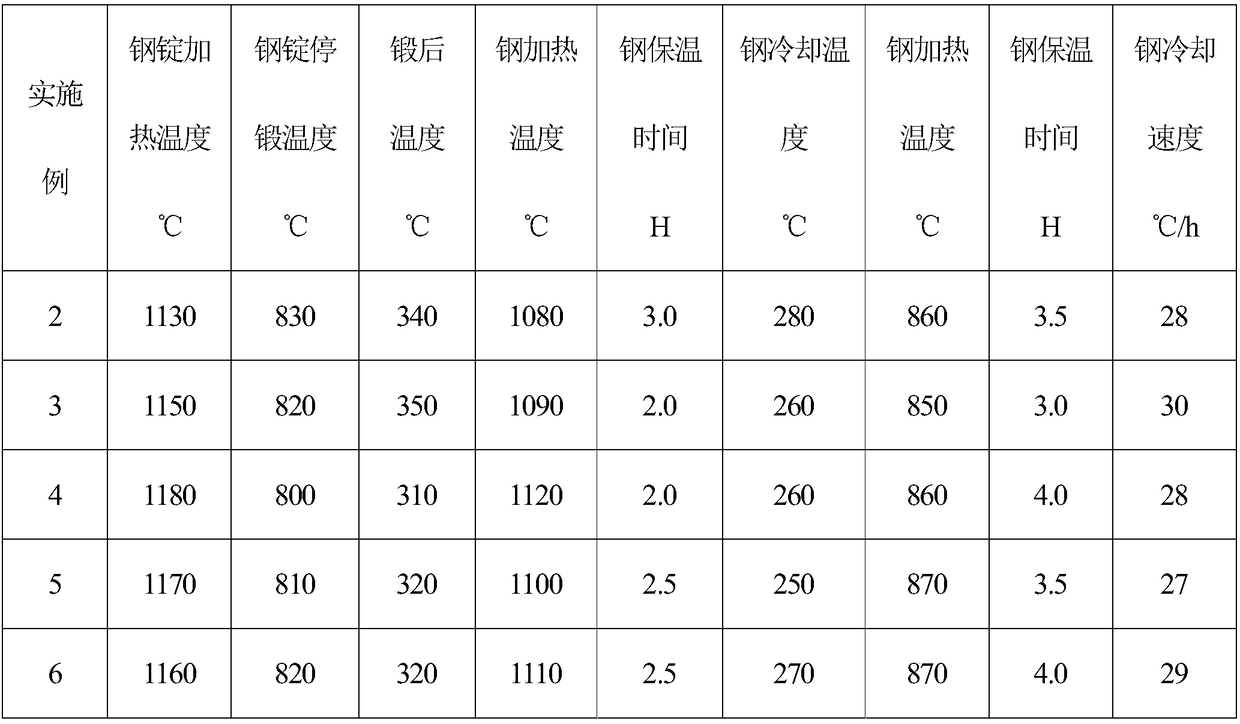

Examples

Embodiment 1

[0051] In this example, the composition and weight percentage of the hot work die steel are as follows:

[0052] C 0.36%, Si 0.27%, Mn 0.30%, Cr 5.35%, Mo 1.78%, V 0.55%, Co 0.23%, P 0.013%, S 0.002%, Fe balance.

[0053] In this embodiment, the process and steps of the strong thermal stability die steel are as follows:

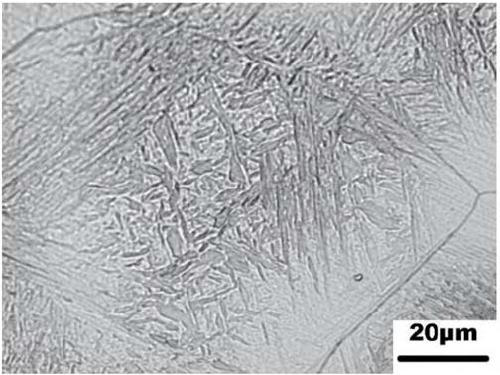

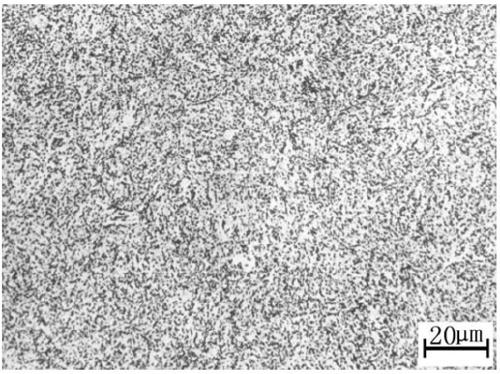

[0054] Control the steel ingot forging according to the chemical composition ratio of the present invention at 1150°C and stop forging at 830°C; air cool to 300°C for the first time after forging; heat the steel to 1050°C for 2.5 hours, and quickly air cool to 280°C ℃; heat the steel again to 840℃ for 3.5 hours to form a fine austenite structure, and slowly cool down to room temperature at less than 25℃ per hour to obtain a fine sorbite microstructure, which meets the high-end requirements Die steel market has strict requirements on material microstructure.

[0055] The high thermal stability die steel of this embodiment has a Rockwell hardness of HRC51.5 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com