A kind of preparation method of high-strength wear-resistant copper alloy pipe

A wear-resistant copper and copper alloy technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of high complexity, long process, and complicated conversion process, and achieve the effect of increasing the effect of dispersion strengthening and improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

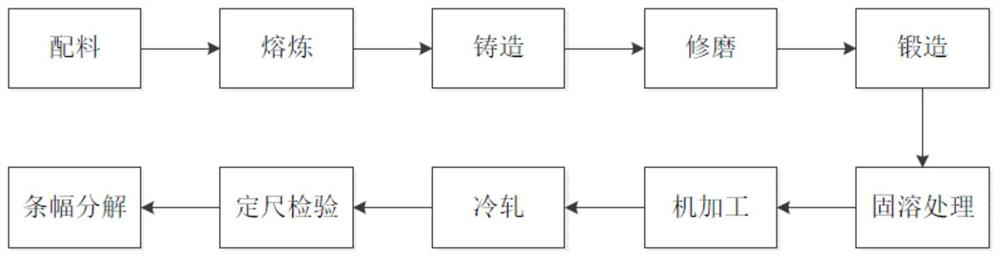

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, a method for producing high-strength copper alloy large-scale ingots by vacuum smelting is obtained by the following method:

[0034] (1) Ingredients: The raw materials used and their ingredients are shown in Table 1.

[0035] Table 1

[0036]

[0037] (2) Melting: Use a vacuum induction furnace for smelting. After the alloy is completely melted, refine for 10 minutes, reduce the power, and fill the argon gas to 0.8×10 5 Pa, add manganese alloy in the upper silo, adjust the power to control the temperature of the molten metal;

[0038] (3) Casting: The molten metal casting temperature is 1250°C, using cast iron molds;

[0039] (4) Grinding: turning and grinding the cooled ingot to remove surface scars, cracks and other defects;

[0040] (5) Forging: use high-frequency induction heating to rapidly heat up to 850°C, hold the heat for 20 minutes, forge the ingot into a bar according to the required tube blank size, ensure that the final forging te...

Embodiment 2

[0048] In this embodiment, a method for producing high-strength copper alloy large-scale ingots by vacuum smelting is obtained by the following method:

[0049] (1) Ingredients: The raw materials used and their ingredients are shown in Table 2.

[0050] Table 2

[0051]

[0052] (2) Melting: use a vacuum induction furnace for melting, after the alloy is completely melted, refine for 15 minutes, reduce the power, and fill the argon gas to 0.85×10 after the surface of the alloy liquid is conjunctival 5 Pa, add manganese alloy in the upper silo, adjust the power to control the temperature of the molten metal;

[0053](3) Casting: The molten metal casting temperature is 1270°C, using cast iron molds;

[0054] (4) Grinding: turning and grinding the cooled ingot to remove surface scars, cracks and other defects;

[0055] (5) Forging: High-frequency induction heating is used to rapidly heat up to 900°C and hold for 10 minutes. The ingot is forged into a bar according to the siz...

Embodiment 3

[0063] In this embodiment, a method for producing high-strength copper alloy large-scale ingots by vacuum smelting is obtained by the following method:

[0064] (1) Ingredients: The raw materials used and their ingredients are shown in Table 3.

[0065] table 3

[0066]

[0067] (2) Melting: Use a vacuum induction furnace for melting. After the alloy is completely melted, refine it for 20 minutes, reduce the power, and fill it with argon to 0.95×10 after the surface of the alloy liquid is formed. 5 Pa, add manganese alloy in the upper silo, adjust the power to control the temperature of the molten metal;

[0068] (3) Casting: The molten metal casting temperature is 1280°C, using cast iron molds;

[0069] (4) Grinding: turning and grinding the cooled ingot to remove surface scars, cracks and other defects;

[0070] (5) Forging: Rapidly heat up to 1000°C by high-frequency induction heating, hold for 5 minutes, forge the ingot into a bar according to the required size of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com