Wave power generation device with rope structure

A wave power generation and rope technology, which is applied to ocean energy power generation, engine components, machines/engines, etc., can solve the problems of low wave energy recovery rate, increase the size of power generation devices, and difficult protection, etc., and achieve high wave energy recovery rate. Low input-output ratio and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

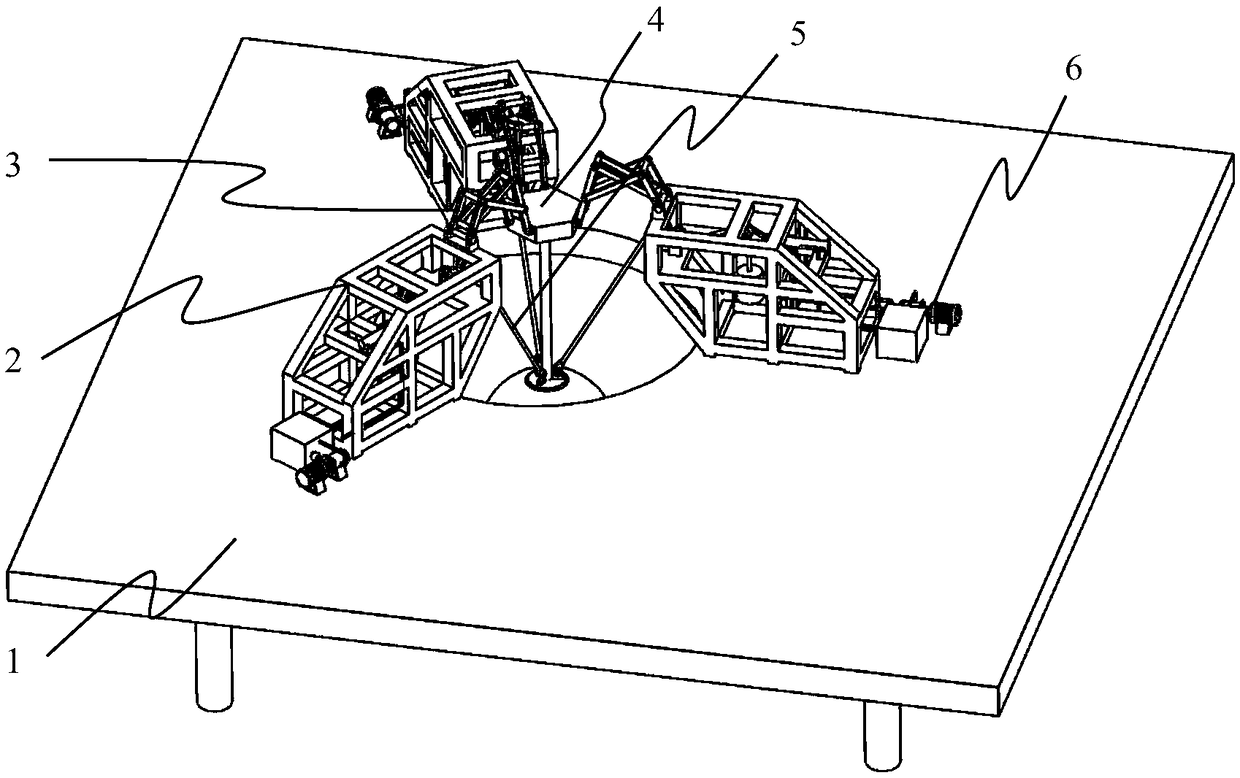

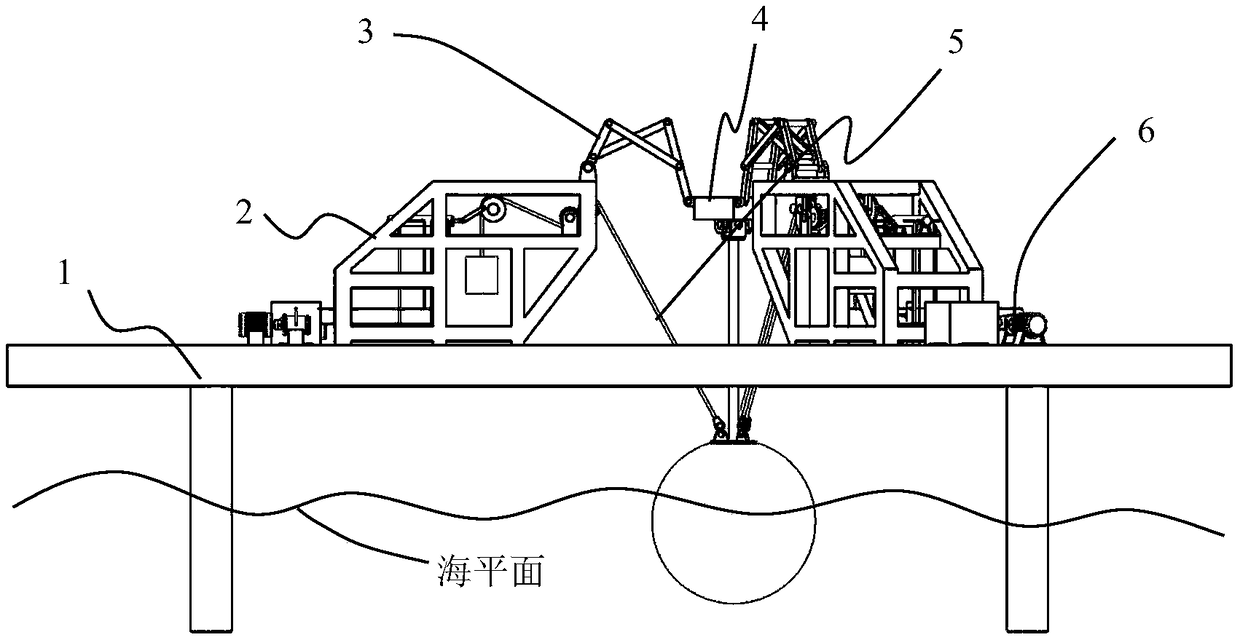

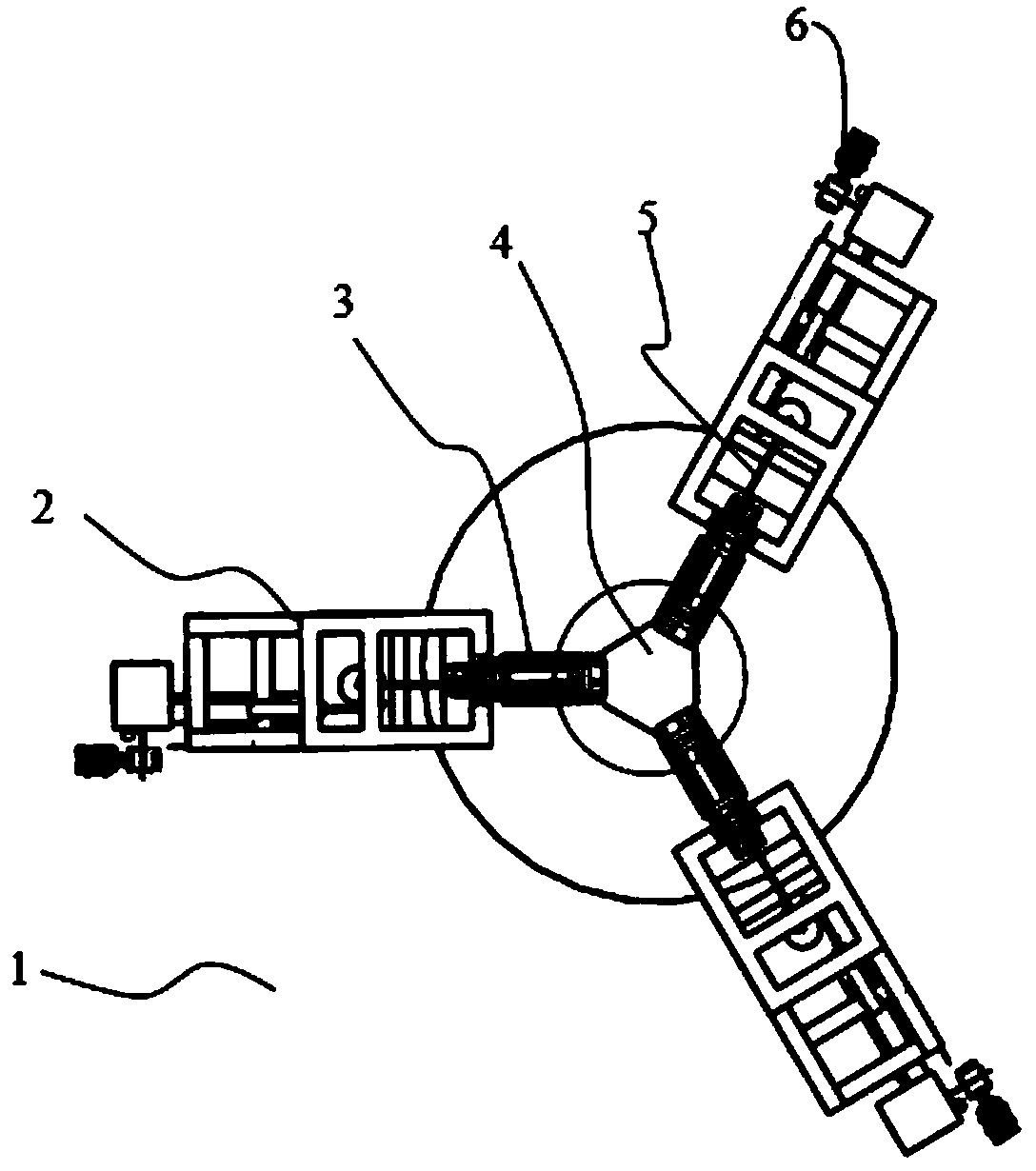

[0026] exist Figure 1 to Figure 8 In the schematic diagram of the present invention shown, the frame assembly 2 mainly includes three frame members 7 with the same structure and uniformly distributed along the circumferential direction, a hydraulic cylinder 34, a third oil inlet 47, a third oil outlet 46, The fourth oil inlet 48, the second oil outlet 45, and the hydraulic cylinder support 8 are provided with a front beam, a rear end beam and an intermediate beam inside the frame member, and the hydraulic cylinder 34 is fixed on the frame member 7 through the hydraulic cylinder support 8. on the rear beam. The front end of the hydraulic cylinder 34 is provided with a third oil inlet 47 and a third oil outlet 46, and the rear end of the hydraulic cylinder 34 is provided with a fourth oil inlet 48 and a second oil outlet 45. Check valves are installed respectively, so that the third oil inlet 47 and the fourth oil inlet 49 can only enter oil, and the second oil outlet 45 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com