3D Force Sensors for Minimally Invasive Medical Devices

A medical device, three-dimensional force technology, applied in the field of medical devices, can solve the problems of the lack of integrated force sensors in minimally invasive medical devices, and achieve the effect of small aspect ratio and good electromagnetic compatibility characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

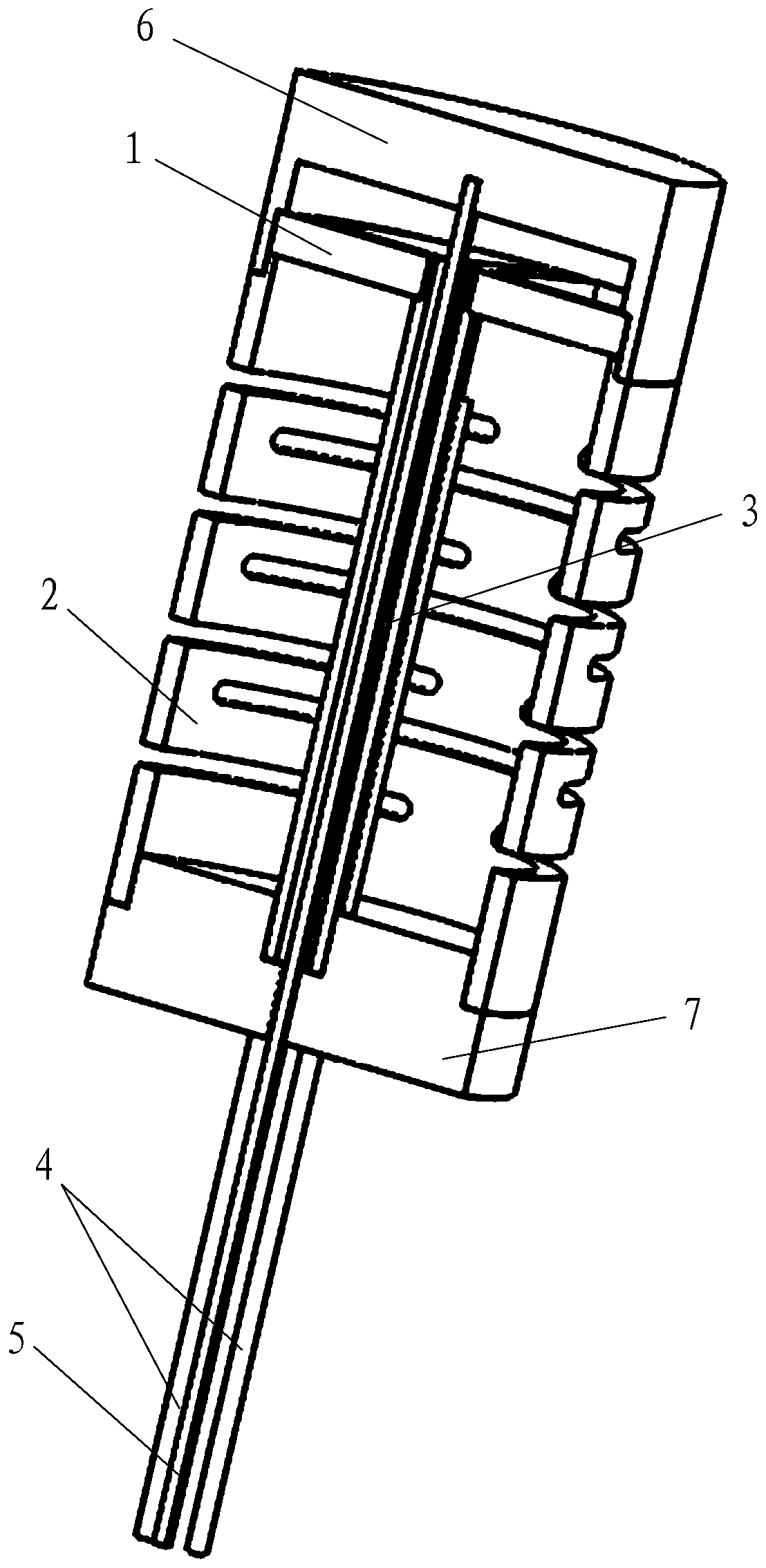

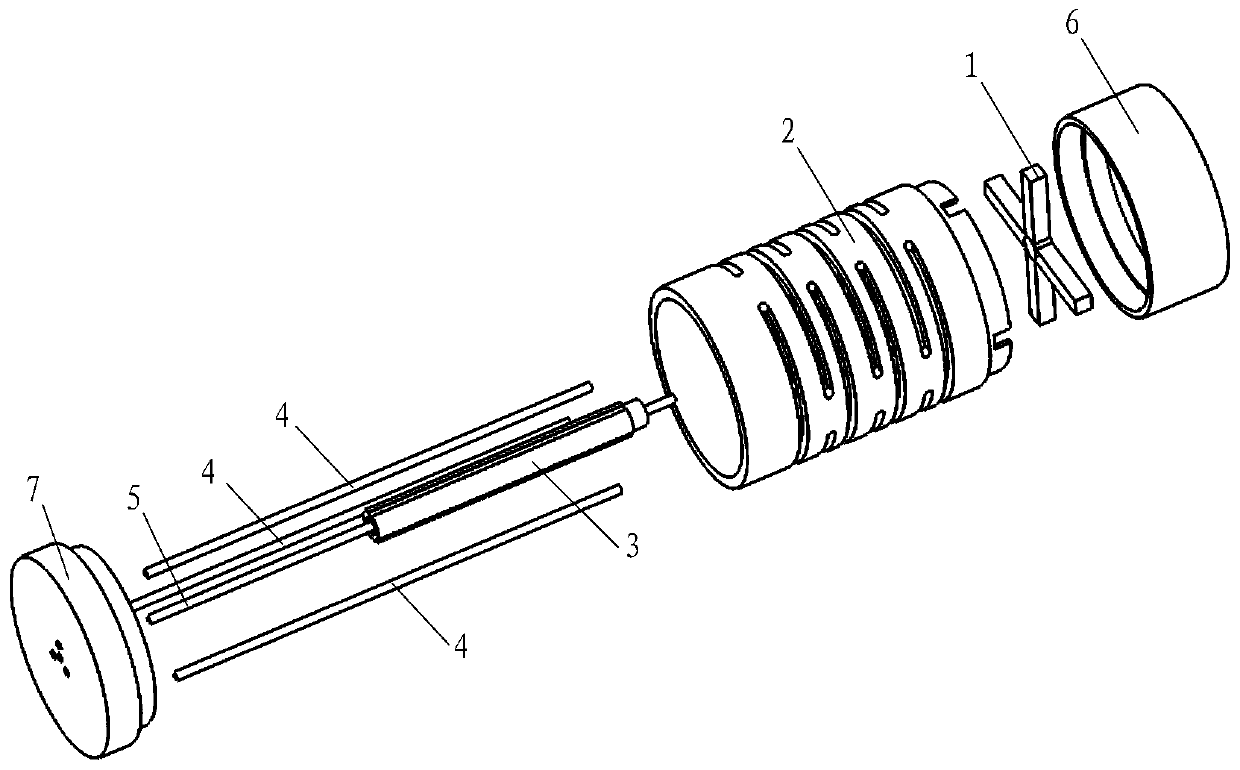

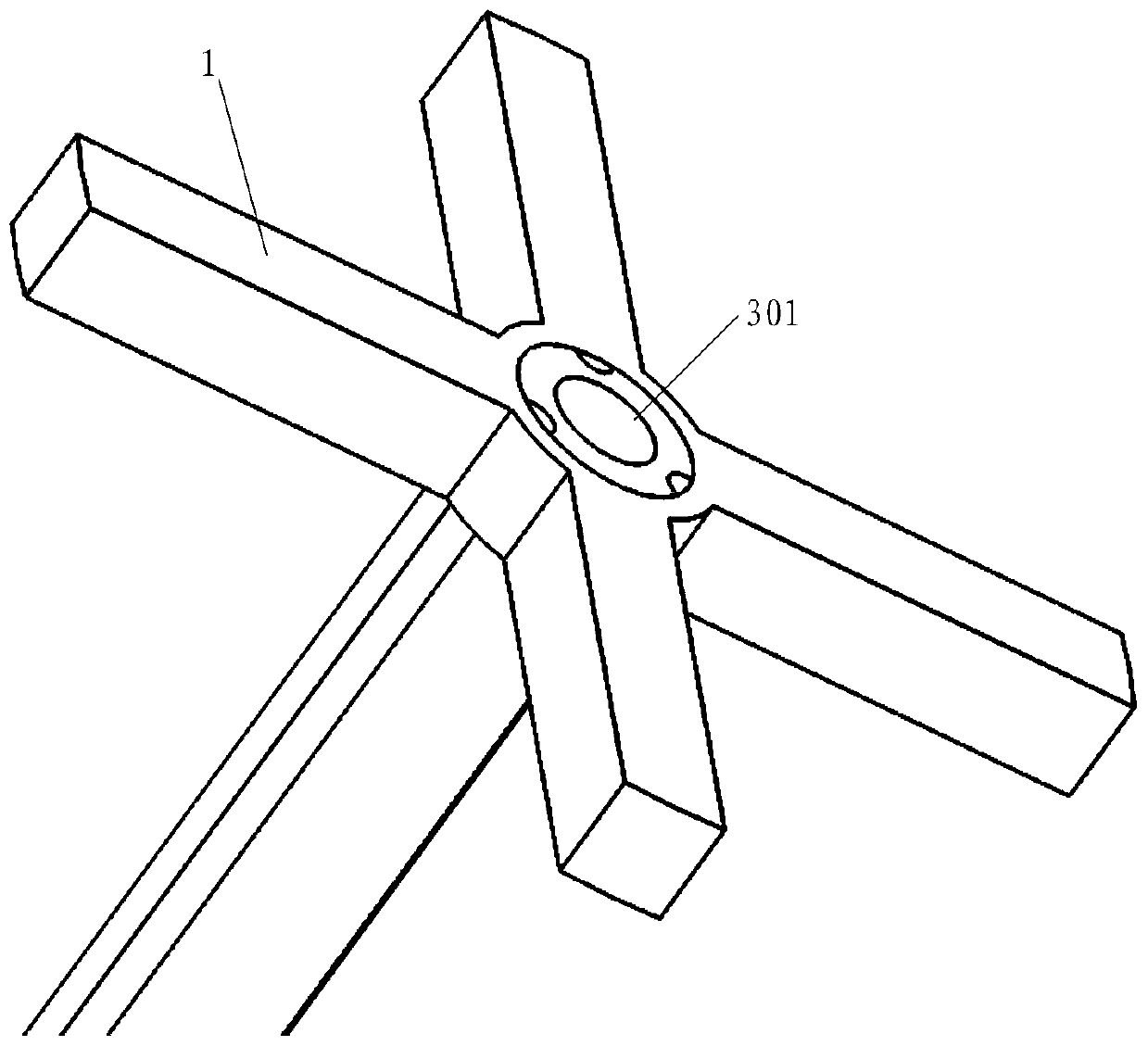

[0030] Such as figure 1 , figure 2 As shown, the present invention includes a leaf spring 1, a grooved outer tube 2, an inner tube 3, an outer optical fiber 4, a central optical fiber 5, an upper base 6 and a lower base 7, wherein the upper and lower ends of the grooved outer tube 2 are respectively connected to The upper base 6 and the lower base 7 are connected, and the outer side of the leaf spring 1 is connected to the upper end of the grooved outer tube 2; The inner side is connected, and the lower end of the inner pipe 3 is connected with the lower base 7 . The central optical fiber 5 passes through the central hole of the inner tube 3, and its two ends are bonded and fixed to the upper and lower bases 6 and 7 respectively, mainly for providing the axial deformation required for axial force detection. A plurality of external optical fibers 4 are eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com