A multifunctional valve hydraulic characteristics and cavitation performance test device

A technology of hydraulic characteristics and testing equipment, which is applied in the direction of measuring equipment, mechanical valve testing, mechanical parts testing, etc., can solve the problems of single function, inconvenient real-time comparison test of multiple valves, high pressure accuracy requirements, etc., to simplify the installation steps , Reduce test time cost, improve test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

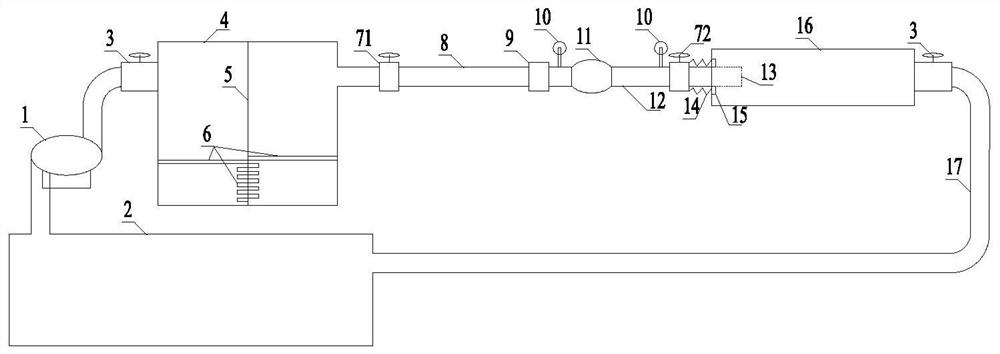

[0048] Taking three pumps and three valves as an example, the specific arrangement of the present invention is the same as figure 1 with 2 . The test device mainly includes: water supply section, test section and return water section.

[0049] The water supply section mainly includes: centrifugal pump 1; circulating reservoir 2; regulating valve 3;

[0050] There are 3 centrifugal pumps, which are driven by 380v motors. Among them, the head of the centrifugal pump needs to be ≥150m head; the inner radius R of the regulating valve 3 1 = 150mm. Circulating reservoir capacity > test system full load capacity + rich water depth capacity (rich water depth 1m) = 16m3 + 16m3 = 32m3 (circulating reservoir length × width × height = 4m × 4m × 2m); the control accuracy of the flow control valve is 0.01Mpa; The control parameters of the voltage stabilizing box are: valve spacing D = 2R 1 =300mm; the length of the surge tank in front of the valve L=6R 1 =900mm; the height of the pre...

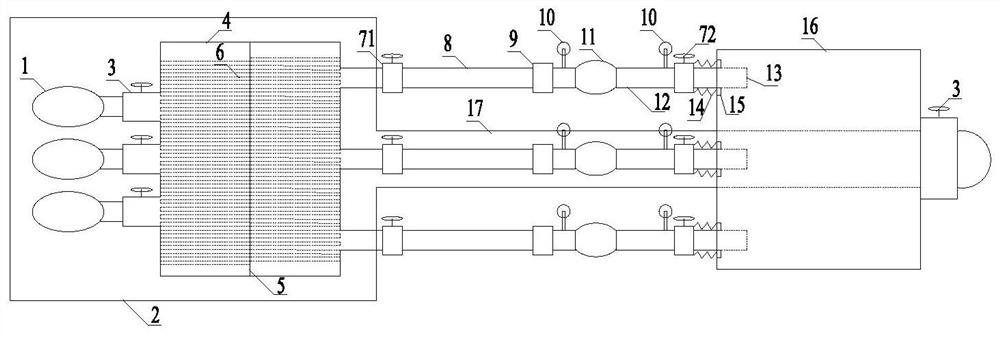

Embodiment 2

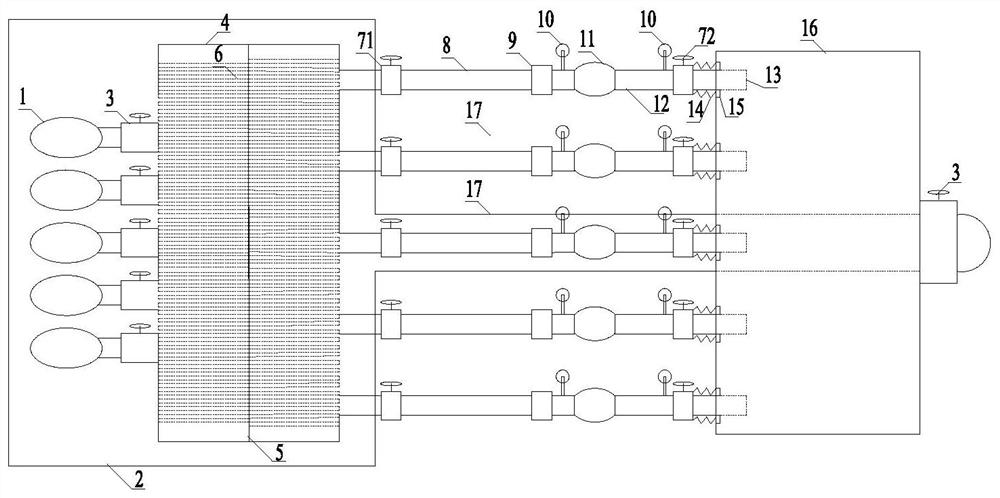

[0063] Taking five pumps and five valves as an example, the specific arrangement of the present invention is the same as figure 1 with 3 . The test device mainly includes three parts: water supply section, test section and return water section.

[0064] The water supply section mainly includes: centrifugal pump 1; circulating reservoir 2; regulating valve 3; There are 5 centrifugal pumps, which are driven by 380v motors. Among them, the head of the centrifugal pump needs to be ≥150m head; the inner radius R of the regulating valve 3 1 = 150 mm. Circulating reservoir capacity > test system full load capacity + rich water depth capacity (rich water depth 1m) = 22m 3 +16m 3 =38m 3 (Length × width × height of the circulating reservoir = 4m × 4m × 2.6m); the control accuracy of the flow regulating valve is 0.01Mpa; the control parameters of the pressure stabilization box before the valve are: valve distance D = 2R 1 =300mm; the length of the surge tank in front of the valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com