In-hole micro-shock sensor fixing and recycling device suitable for different apertures

A technology of microseismic sensor and recovery device, which is applied in the direction of seismic signal receivers, etc., can solve problems such as inability to receive signals well, large borehole diameter, and difficulty in realization, and achieve good market prospects, improve accuracy, and facilitate installation and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

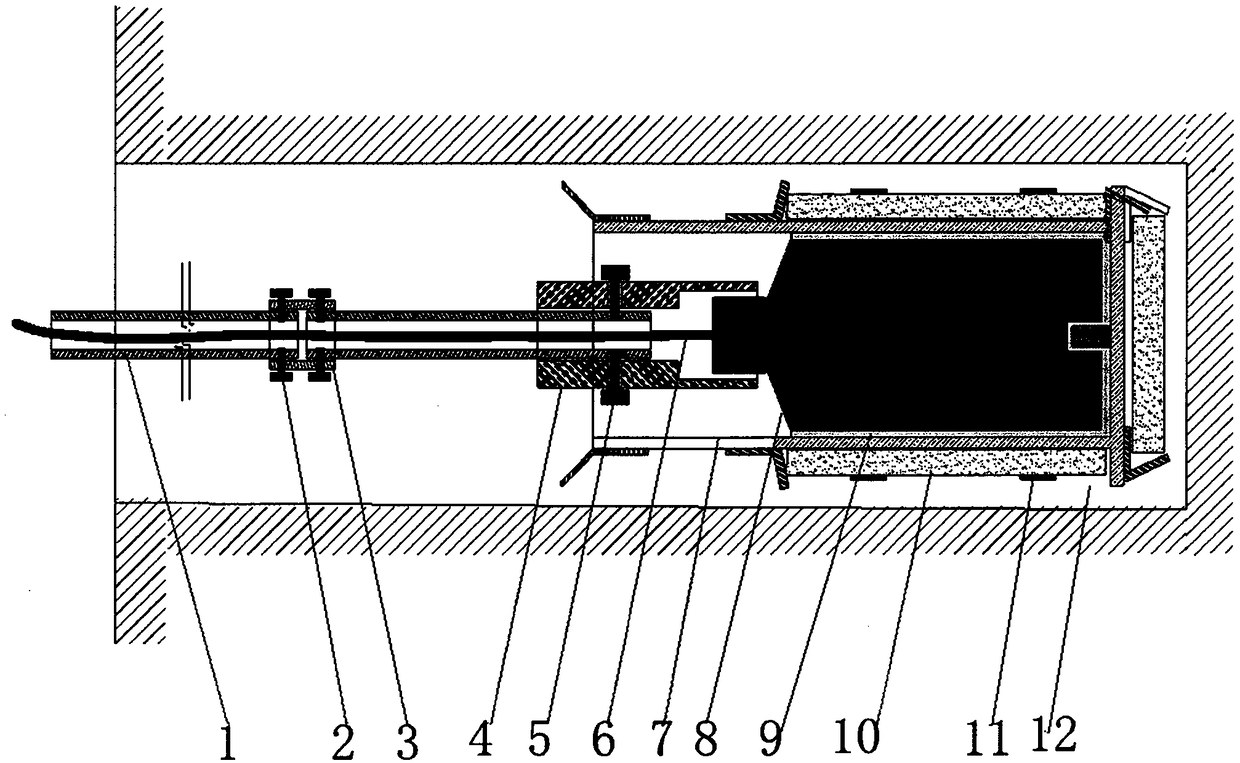

[0064] Such as figure 1 As shown, a microseismic sensor fixing and recovery device suitable for different apertures, including:

[0065] The installation base 7 is equipped with a sensor 8 inside, and the installation base 7 is welded by the center anchor claw 7-1, the sensor sleeve 7-2, the limit anchor claw 7-3 and the drug roll fixing claw 7-5, wherein :

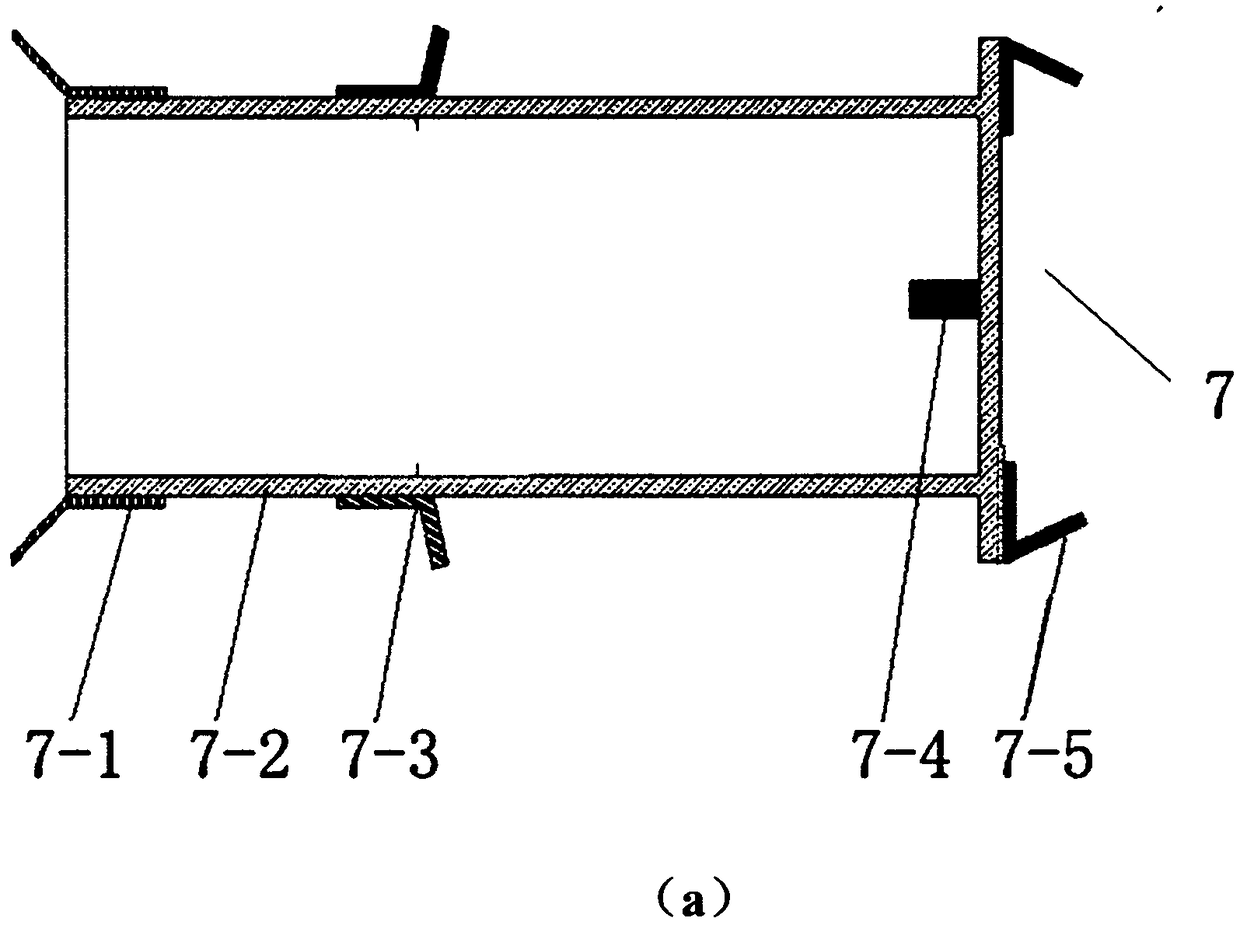

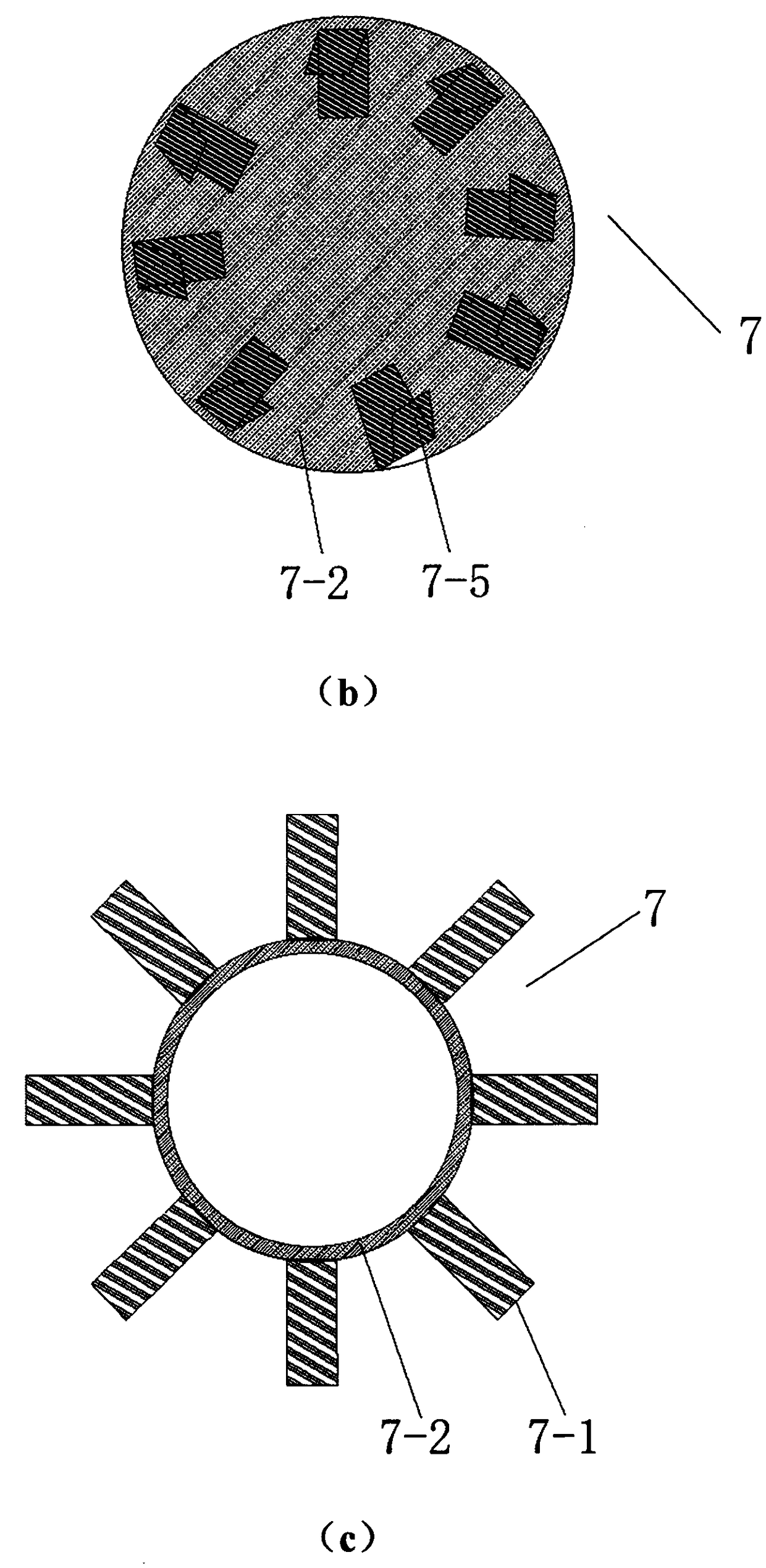

[0066] Such as figure 2 As shown in (a), the sensor sleeve 7-2 is a cylindrical structure with an open top, and the center anchor fluke 7-1, the limit anchor fluke 7-3 and the drug coil fixing claw 7-5 are welded to the sensor sleeve 7-2. On the outer wall; the centering anchor fluke 7-1, the limit anchor fluke 7-3 and the drug volume fixing claw 7-5 are formed by bending a metal sheet, and the cross section is an irregular "L"-shaped sheet structure;

[0067] Such as figure 2 (a) and figure 2 (c) The centering fluke 7-1 shown in (c) is set along the circumference of the top of the sensor sleeve 7-2, the number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com