Puffed wheat bran cereal food and manufacturing method thereof

A technology of puffed grains and wheat bran, applied in the field of snack food, can solve the problems of obesity, low dietary fiber content, high oil and high sugar, etc., and achieve the effect of protecting intestinal mucosa and preventing colon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

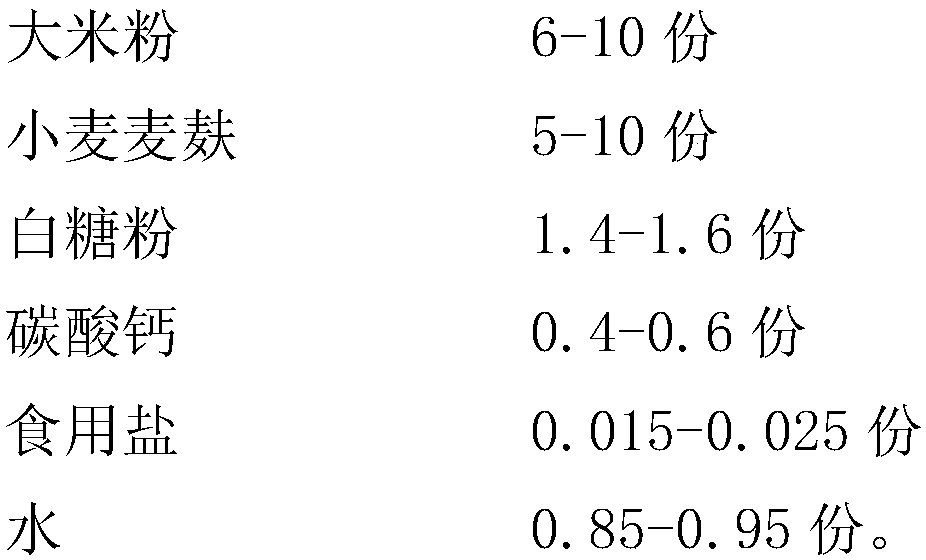

[0027] A wheat bran puffed cereal food made from the following ingredients by weight:

[0028]

[0029] A method for preparing wheat bran puffed cereal food, comprising the following steps:

[0030] 1. Mixed powder

[0031] Add edible vegetable oil, rice flour, wheat bran, white sugar powder, calcium carbonate, and edible salt into the powder blender and mix for 1.5 minutes, stir evenly, add water, stir and mix for 3 minutes, and mix well to obtain a wet powder;

[0032] 2. Forming

[0033] The twin-screw extrusion equipment is used to form the wet powder obtained in step 1. The twin-screw extrusion equipment includes four temperature control zones: zone I, zone II, zone III, and zone IV. The temperature is respectively set as: zone I 30°C, zone II 87.5°C, zone III 120°C, zone IV 132.5°C; when the temperature of the four temperature control zones of the twin-screw extrusion equipment reaches the set temperature, step one The prepared wet powder is evenly fed through the ...

Embodiment 2

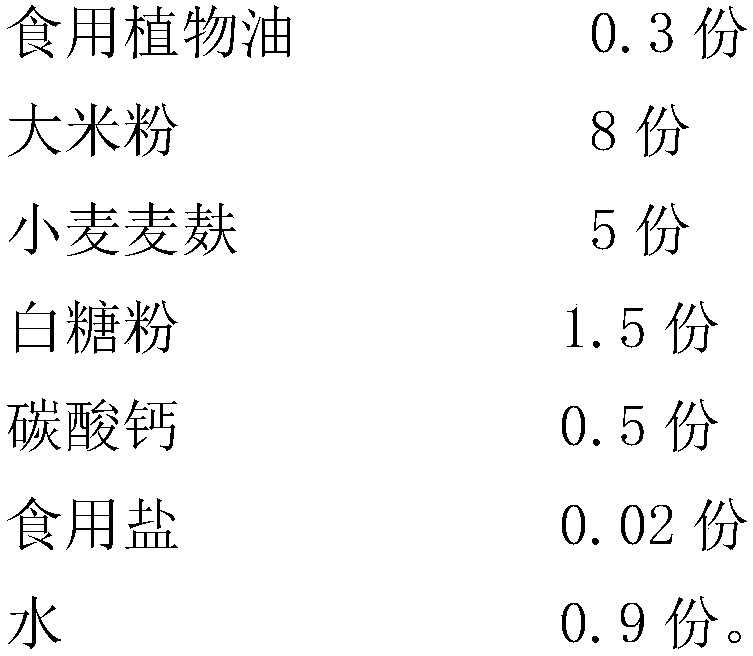

[0037] A wheat bran puffed cereal food is made from the following raw materials in parts by weight:

[0038] Edible vegetable oil 0.2kg

[0039] Rice flour 6kg

[0040] Wheat bran 5kg

[0041] White sugar powder 1.4kg

[0042] Calcium carbonate 0.4kg

[0043] Edible salt 0.015kg

[0044] 850ml of water.

[0045] A method for preparing wheat bran puffed cereal food, comprising the following steps:

[0046] 1. Mixed powder

[0047] Add edible vegetable oil, rice flour, wheat bran, white sugar powder, calcium carbonate, and edible salt into the powder blender and mix for 1 minute, stir well, add water, stir and mix for 2 minutes, and mix well to obtain wet powder;

[0048] 2. Forming

[0049] The twin-screw extrusion equipment is used to form the wet powder obtained in step 1. The twin-screw extrusion equipment includes four temperature control zones: zone I, zone II, zone III, and zone IV. The temperature is respectively set as: Zone I 40°C, Zone II 85°C, Zone III 115°C...

Embodiment 3

[0053] A wheat bran puffed cereal food is made from the following raw materials in parts by weight:

[0054] Edible vegetable oil 0.4kg

[0055] Rice flour 10kg

[0056] Wheat bran 10kg

[0057] White sugar powder 1.6kg

[0058] Calcium carbonate 0.6kg

[0059] Edible salt 0.025kg

[0060] 950ml of water.

[0061] A method for preparing wheat bran puffed cereal food, comprising the following steps:

[0062] 1. Mixed powder

[0063] Add edible vegetable oil, rice flour, wheat bran, white sugar powder, calcium carbonate, and edible salt into the powder blender and mix for 2 minutes, stir evenly, add water, stir and mix for 4 minutes, and mix well to obtain a wet powder;

[0064] 2. Forming

[0065] The twin-screw extrusion equipment is used to form the wet powder obtained in step 1. The twin-screw extrusion equipment includes four temperature control zones: zone I, zone II, zone III, and zone IV. The temperature is respectively set as: Zone I 50°C, Zone II 90°C, Zone III ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com