A kind of self-adjusting type transparent composite airgel and preparation method thereof

A composite aerogel and self-adjusting technology, which is applied in the field of transparent composite aerogel and its preparation, self-adjusting transparent composite aerogel and its preparation field, can solve the problems of affecting indoor natural lighting and unfavorable winter heating, etc. , to achieve the effects of low cost, excellent thermal insulation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

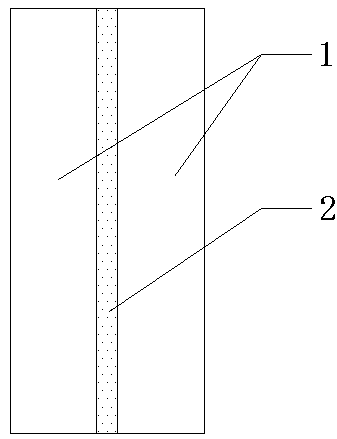

Image

Examples

preparation example Construction

[0036] Another embodiment of the present invention, a method for preparing a self-adjusting transparent composite airgel, is characterized in that it comprises the following steps:

[0037] (1) Preparation of matrix gel, mix and stir organosilane, deionized water, organic solvent and acid catalyst, hydrolyze for 4~60h, add alkali catalyst, stir, react for 0.01~1h to obtain silica sol, gel, A matrix gel is obtained, wherein the volume ratio of organosilane, deionized water, organic solvent, acid catalyst, and base catalyst is 1:0.05~5:0.5~8:0.0025~0.5:0.0025~0.5;

[0038] (2) Preparation of thermochromic gel, prepare silica sol according to step (1), and then VO 2 The nanoparticle dispersion is added to the silica sol, stirred evenly, and then cast onto the surface of the matrix gel obtained in step (1), and quickly gelled by chemical catalysis or high-energy catalysis to obtain a thermochromic gel, wherein VO 2 The volume ratio of nanoparticle dispersion to silica sol is 0.00...

Embodiment 1

[0053] (1) At 40°C, mix and stir methyl orthosilicate, deionized water, methanol, and dilute hydrochloric acid, stir and react for 40 hours, then add dilute ammonia water, stir, and react for 0.5 hours to obtain silica sol, gel, and matrix Gel, wherein the volume ratio of methyl orthosilicate, deionized water, methanol, dilute hydrochloric acid, and dilute ammonia water is 1:0.1:0.5:0.0025:0.025, and the concentration of dilute hydrochloric acid and dilute ammonia water is 0.3mol / L;

[0054] (2) Prepare silica sol according to the method of step (1), and then VO 2 Add the nanoparticle alcohol dispersion to the silica sol, stir evenly, and then cast it on the surface of the matrix gel, and use microwave catalysis to make VO 2 The nanoparticles are evenly distributed in the silica sol and quickly gel to obtain a thermochromic gel, in which VO 2 The volume ratio of the nanoparticle alcohol dispersion to the silica sol is 0.001%;

[0055] (3) Preparation of composite gel, prepar...

Embodiment 2

[0058] (1) At 0°C, mix and stir ethyl orthosilicate, deionized water, ethanol, and dilute hydrochloric acid, stir and react for 60 hours, then add aqueous sodium hydroxide solution, stir, and react for 1 hour to obtain silica sol, gel, and Matrix gel, in which the volume ratio of ethyl orthosilicate, deionized water, ethanol, dilute hydrochloric acid, and aqueous sodium hydroxide solution is 1:0.05:8:0.5:0.0025, and the concentration of dilute hydrochloric acid and aqueous sodium hydroxide solution is 0.3 mol / L;

[0059] (2) Prepare silica sol according to the method of step (1), and then VO 2 The aqueous dispersion of nanoparticles is added to the silica sol, stirred evenly, and then cast on the surface of the matrix gel, and VO is catalyzed by chemical acid and alkali. 2 The nanoparticles are evenly distributed in the silica sol and quickly gel to obtain a thermochromic gel, in which VO 2 The volume ratio of the nanoparticle aqueous dispersion to the silica sol is 0.5%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com