Soil remediation agent dispensing configuration method

A configuration method and soil remediation technology, applied in the restoration of contaminated soil, chemical instruments and methods, mixers, etc., can solve the problem of inability to adjust the initial height of dispensing, and achieve environmental protection and sanitation during the operation process, ensure uniformity, and performance reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

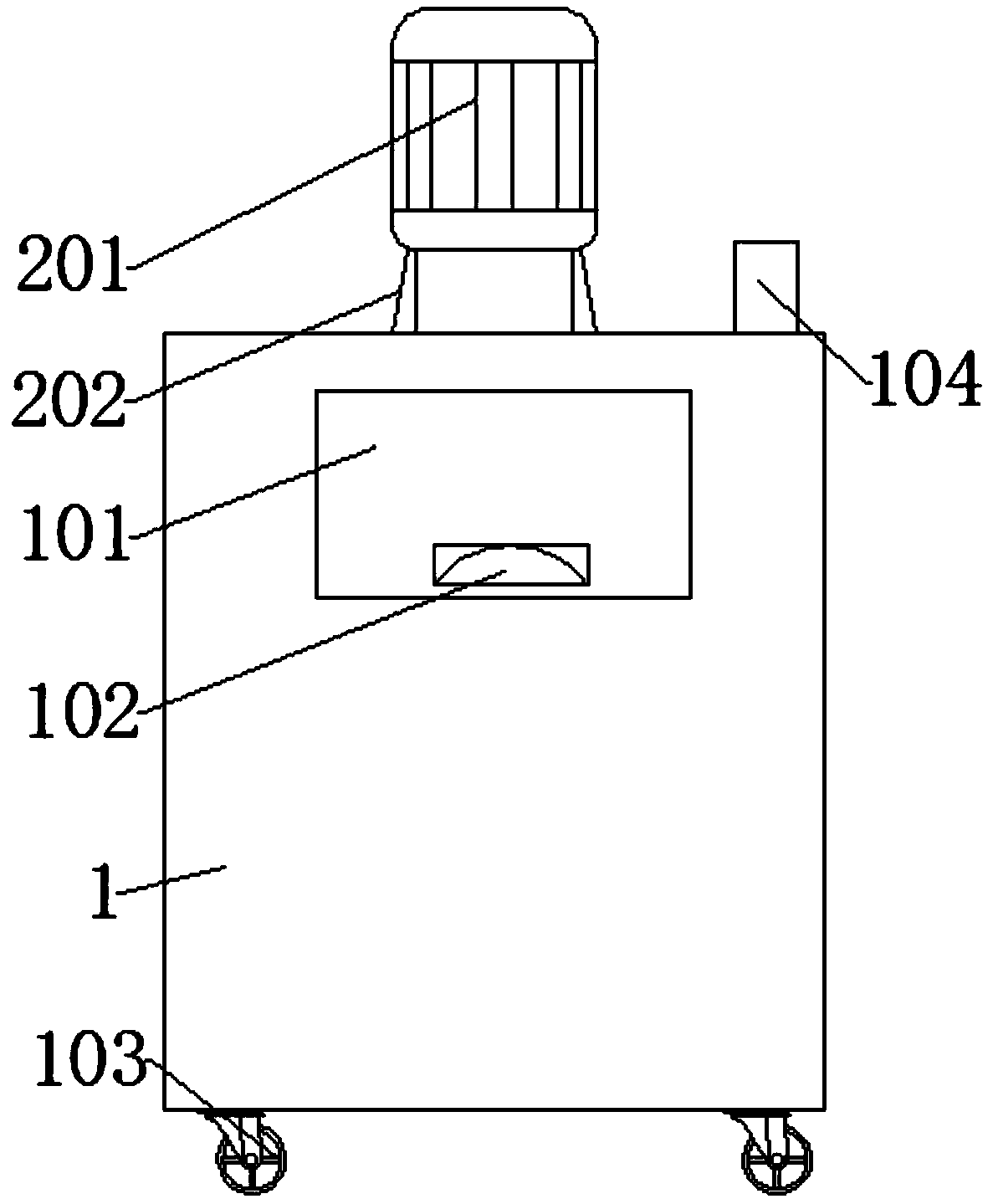

[0023] The first embodiment: see Figure 1-Figure 3 As shown, the present invention provides a dispensing device for soil remediation, comprising a casing body 1 and casters 103, the bottom surface of the casing body 1 is fixed with casters 103, the front of the casing body 1 is provided with a cover plate 101, and the surface of the cover plate 101 is A handle 102 is fixedly installed, a liquid inlet pipe 104 is fixedly installed on the top surface of the casing body 1, and a dispensing component 2 is arranged on the side of the liquid inlet pipe 104;

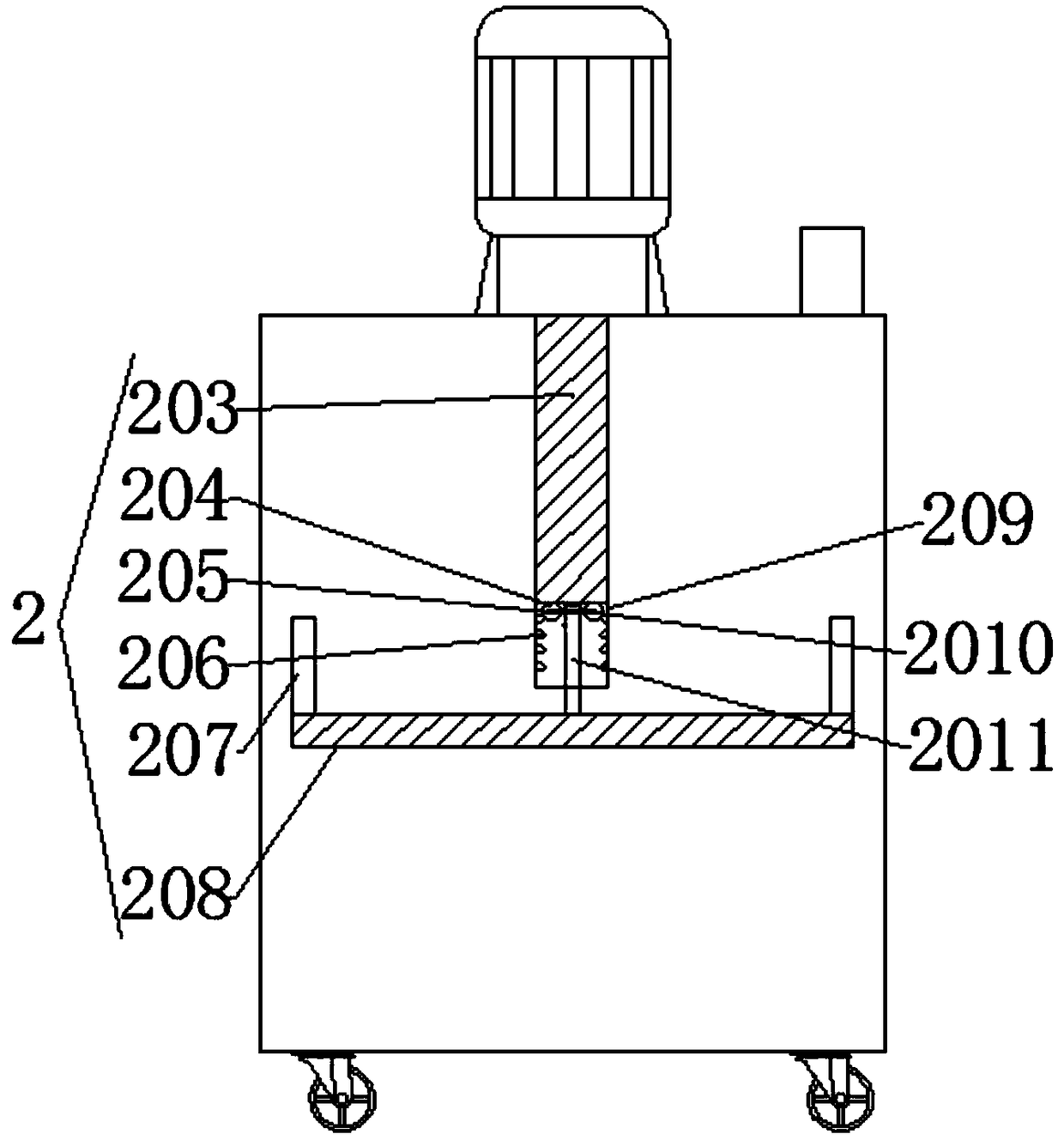

[0024] The dispensing assembly 2 includes a motor base 202 and a servo motor 201. A servo motor 201 is fixedly installed on the top surface of the motor base 202. A rotating shaft 203 is fixedly installed on the bottom surface of the servo motor 201. A casing 209 is arranged inside the end of the rotating shaft 203. There is a bump 206, a roller 204 is arranged on the outside of the edge of the bump 206, a wheel frame 205 is a...

no. 2 approach

[0032] The second embodiment: a dispensing device for soil remediation, including a casing body 1 and casters 103, the bottom surface of the casing body 1 is fixed with the casters 103, and the front of the casing body 1 is provided with a cover plate 101, A handle 102 is fixedly installed on the surface of the cover plate 101, a liquid inlet pipe 104 and a feeding pipe are fixedly installed on the top surface of the casing body 1, and a dispensing assembly 2 is arranged on the side of the liquid inlet pipe 104;

[0033] The dispensing assembly 2 includes a motor base 202 and a servo motor 201, the servo motor 201 is fixedly installed on the top surface of the motor base 202, the servo motor 201 works in two modes of high and low speed, and the low speed mode is used for uniform Feed to the storage rack, the high-speed mode is used for uniform stirring; the bottom surface of the servo motor 201 is fixedly equipped with a rotating shaft 203, and the inner side of the end of the ...

no. 3 approach

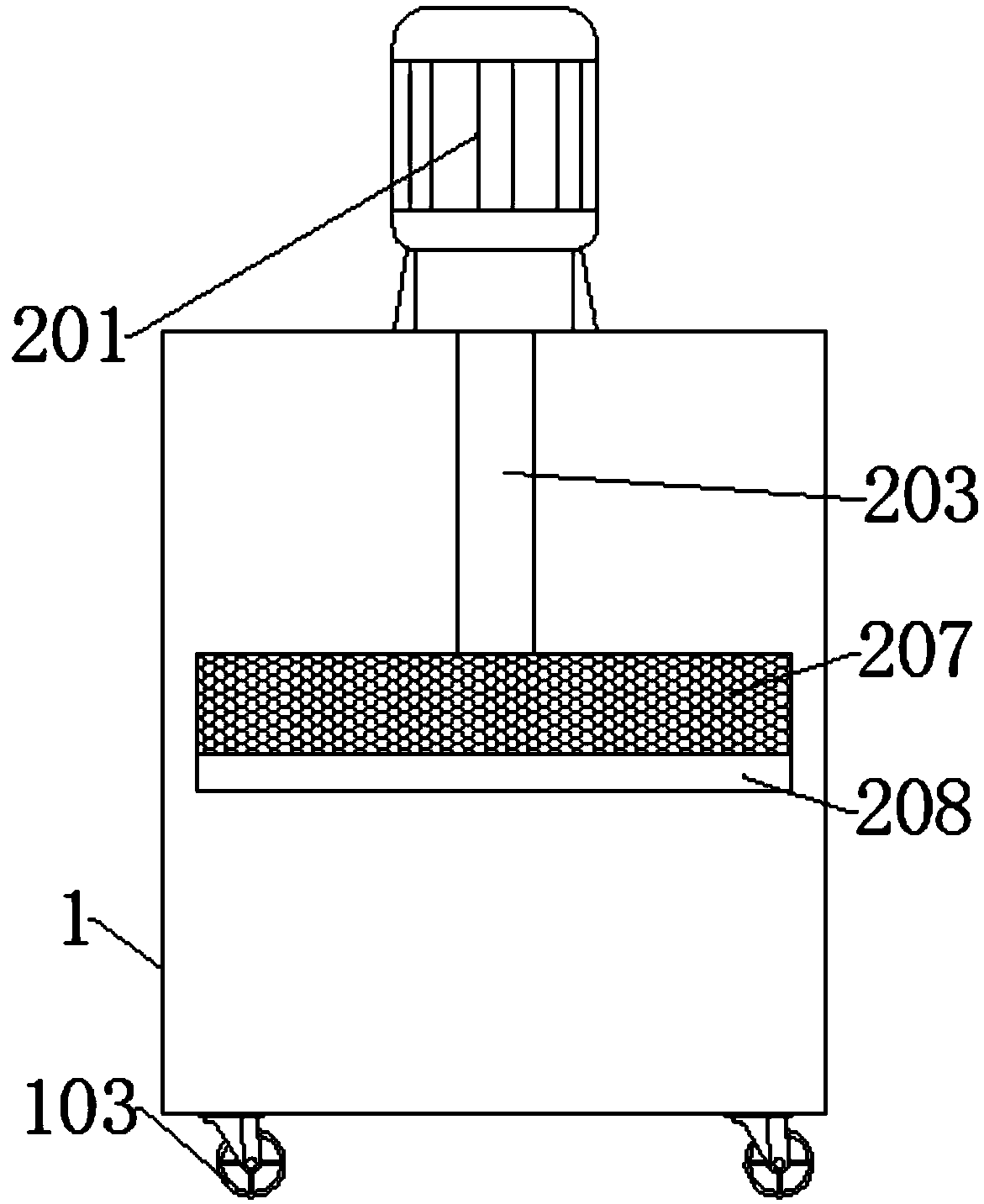

[0040] The third embodiment: a dispensing and configuration method for soil remediation. By mixing the solid medicine and the liquid medicine uniformly according to a certain ratio, first inject the target amount of liquid medicine into the airtight container 1 through a liquid inlet pipe 104, and then according to the According to the above ratio, a shelf 208 loaded with solid medicament is immersed into the target depth of the liquid medicament and rotated at a high speed. thrown out, and evenly mixed with the liquid medicine, wherein the shelf utilizes the guard plate 207 set on it to form a semi-closed solid medicine storage space;

[0041] In the early stage of the above-mentioned mixing operation, the rack 208 is moved upward to a suitable position by holding the feeding pipe and the liquid inlet pipe 104 with both hands respectively, and the solid medicament feeding operation is performed, and the feeding pipe and the liquid inlet pipe 104 are jointly connected to the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com