Synthesis technology of Pt-Co cube nanocrystalline

A synthesis process, cube technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as inconvenient operation, high cost, and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

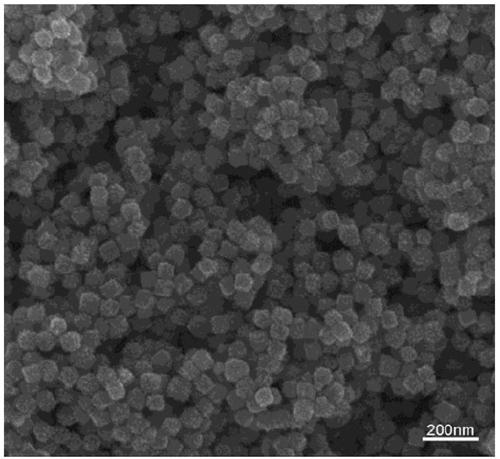

Embodiment 1

[0037] In a 25ml flask, weigh 10mg platinum acetylacetonate, 6.65mg cobalt acetylacetonate, and 80mg tetraoctylammonium bromide respectively, add 5mL oleylamine, and then add 20 μL (15.46 mg) triisopropylsilane to the reaction system, Sonicate for 8 minutes to disperse the mixture in the bottle evenly in the solvent. The flask should be sealed with Teflon tape. Then place the flask in an oil bath, raise the temperature of the reaction system with the oil, and raise the temperature of the reaction system to 190° C. within 30 minutes, and keep the reaction system at 190° C. for 15 hours.

[0038] After the reaction was completed, the reaction system was naturally cooled to room temperature, and then 30 mL of ethanol was added to the colloidal product, ultrasonically dispersed, and centrifuged at 5000 r / min for 2 min. Then the supernatant was discarded, and the powder of the lower layer was left, washed 6 times with 30 mL of ethanol, and centrifuged at 5000 r / min for 2 min. The...

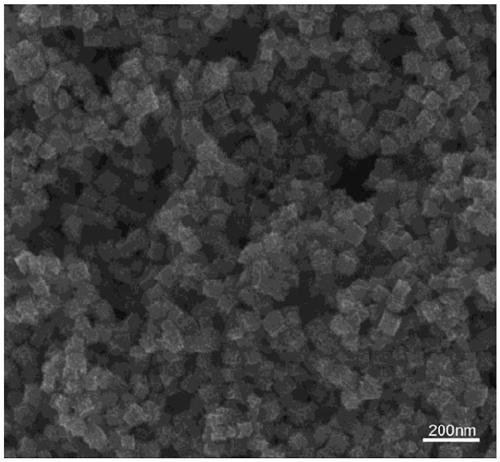

Embodiment 2

[0041] In a 25ml flask, weigh 10mg of platinum acetylacetonate, 6.65mg of cobalt acetylacetonate, and 170mg of tetraoctylammonium bromide, add 5mL of oleylamine, and then add 20mg of n-hexadecanyl formamide to the reaction system, and ultrasonically For 20 minutes, the mixture in the bottle was evenly dispersed in the solvent. The flask should be sealed with Teflon tape. Then place the flask in an oil bath, raise the temperature of the reaction system with the oil, and raise the temperature of the reaction system to 190° C. within 30 minutes, and keep the reaction system at 190° C. for 15 hours.

[0042]After the reaction was completed, the reaction system was naturally cooled to room temperature, and then 35 mL of ethanol was added to the colloidal product, ultrasonically dispersed, and centrifuged at 5000 r / min for 2 min. Then discard the supernatant, keep the lower layer of powder, and wash 7 times with 30 mL of ethanol, and centrifuge at 5000 r / min for 2 min. The finally...

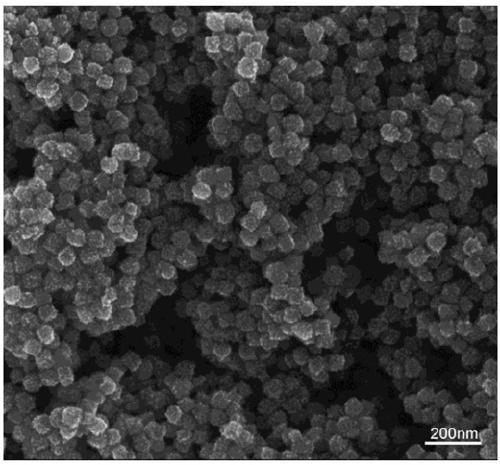

Embodiment 3

[0045] In a 25ml flask, weigh 10mg platinum acetylacetonate, 6.65mg cobalt acetylacetonate, 170mg tetraoctylammonium bromide, add 5mL oleylamine, then add 80μL (61.8mg) triisopropylsilane to the reaction system, Sonicate for 20 minutes to disperse the mixture in the bottle evenly in the solvent. The flask should be sealed with Teflon tape. Then place the flask in an oil bath, raise the temperature of the reaction system with the oil, and raise the temperature of the reaction system to 190° C. within 30 minutes, and keep the reaction system at 190° C. for 15 hours.

[0046] After the reaction was completed, the reaction system was naturally cooled to room temperature, and then 40 mL of ethanol was added to the colloidal product, ultrasonically dispersed, and centrifuged at 5000 r / min for 2 min. Then discard the supernatant, leave the lower layer of powder, and wash with 30 mL of ethanol 8 times, also centrifuged at 5000 r / min for 2 min. The finally obtained samples are Pt-Co ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com