Optimizing method for reducing equilibrium amount of push type clutch cover

An optimization method and technology of clutch cover, applied in the field of clutch cover, can solve the problems of poor concentricity between the transmission plate hole and the outer circle, inaccurate positioning of parts, unsatisfactory verticality, etc., and achieve smooth appearance quality, smooth lines, processing quality and precision. Warranty, longevity and appearance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

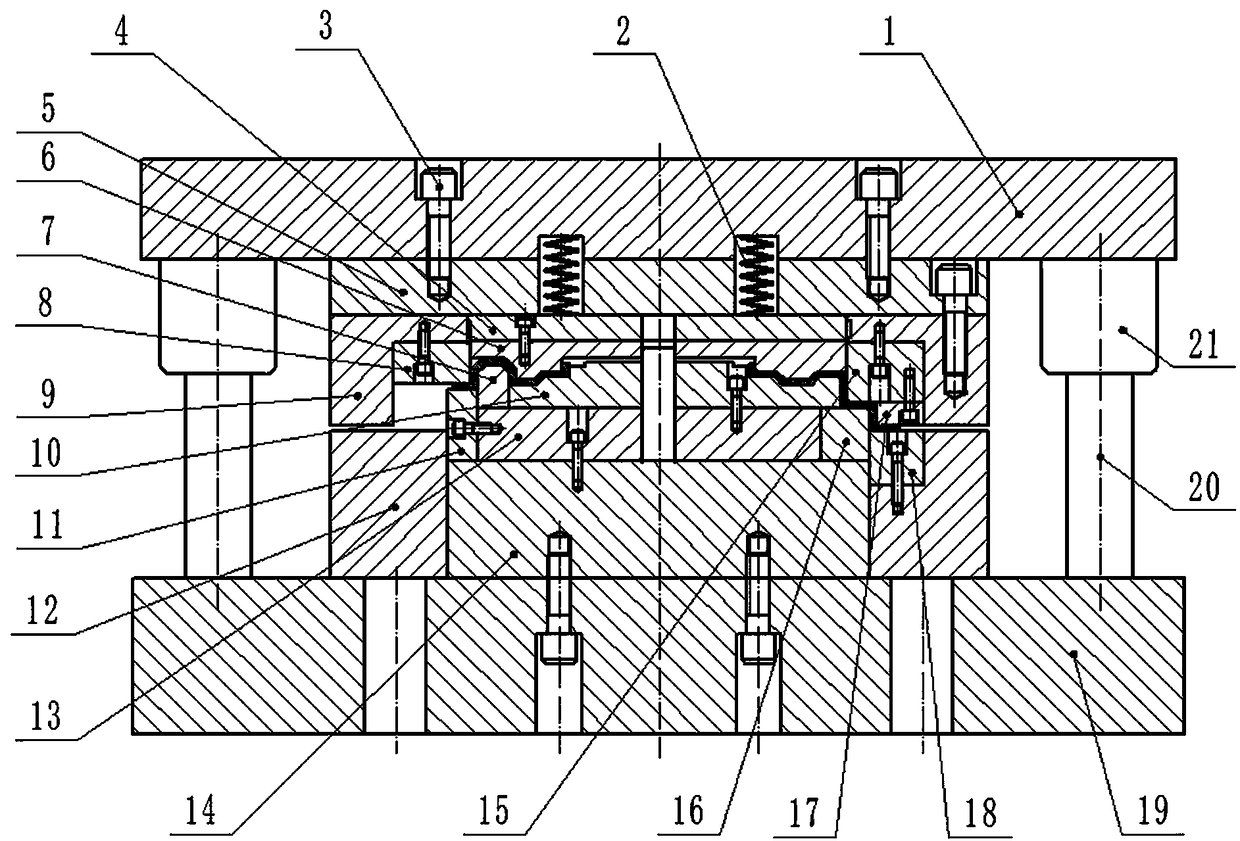

[0028] The present invention is an optimization method for reducing the balance of the push clutch cover, the steps are as follows:

[0029] (1) Blanking and punching the middle hole: the outer shape and the middle shape of the cover are dropped once through the above-mentioned mold with a gap on the punching machine;

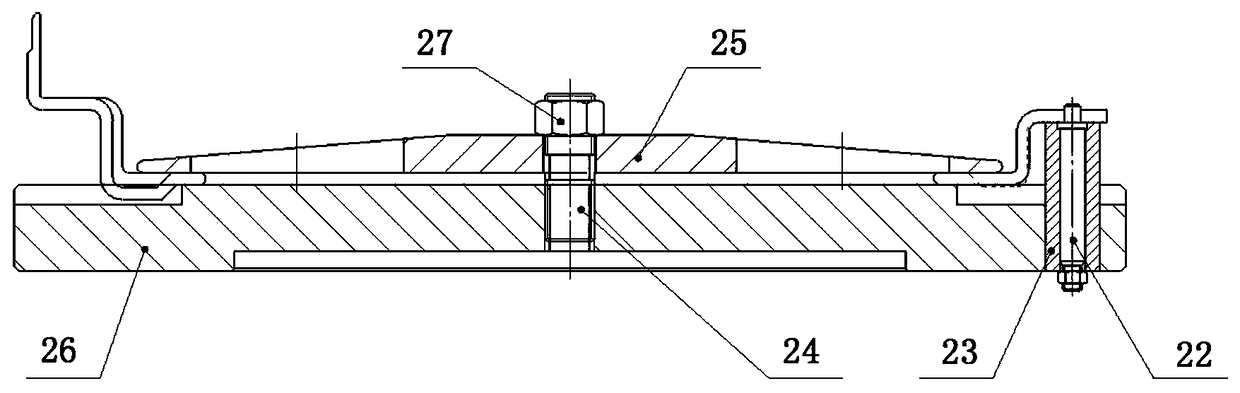

[0030] (2) Forming: the shape of the cover is formed on the press machine through a forming die;

[0031] (3) The end face of the center hole in the car: on the CNC lathe, the end face of the center hole is loaded on the CNC lathe and the diameter of the center hole is repaired to facilitate precise positioning later;

[0032] (4) Punching installation holes, transmission hole and notch: directly punch out the installation hole, transmission hole and notch by punching the installation hole, transmission hole and notch mold on the punching machine;

[0033] (5) Punching the diaphragm hole: directly punch out the diaphragm hole through the punching diaphragm hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com