An online detection method for a flexible production line for small workpieces

A flexible production line and detection method technology, which is applied to metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to measure workpieces, many human interventions, and low efficiency, and achieve improved pass rate, unified benchmarks, and reduced The effect of measurement system error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

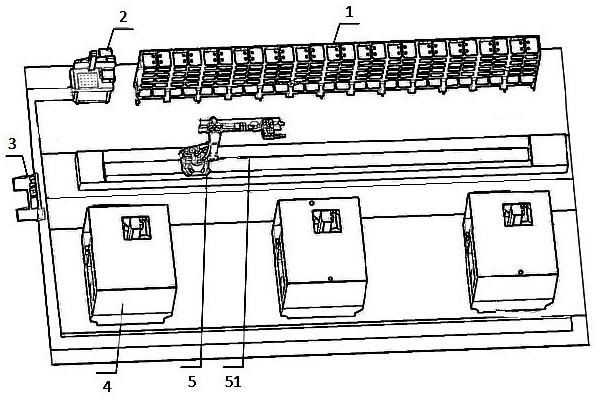

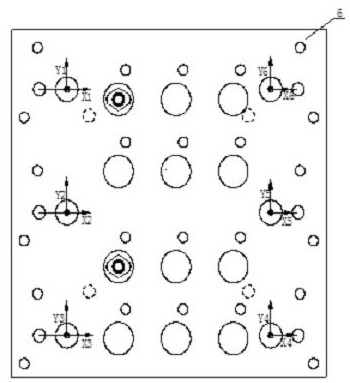

[0042] The present invention is realized through the following technical solutions, as figure 1 , image 3 As shown, an online detection device for a flexible production line of small workpieces is used in conjunction with multiple CNC machine tools 4 and installed on a console, including a material rack 1, a measuring machine 2, a master console 3, a loading and unloading robot 5, and a The zero point positioning base 7 on the measuring machine 2 and a plurality of numerically controlled machine tools 4 and the zero point positioning tray 6 used to clamp the workpiece in cooperation with the zero point positioning base 7; the measuring machine 2 and the numerically controlled machine tools 4 are arranged linearly, so The loading and unloading robot 5 is arranged between the material rack 1 and the CNC machine tool 4; the master console 3 communicates with the loading and unloading robot 5, the measuring machine 2, and 4 CNC machine tools; the material rack 1, the measuring ma...

Embodiment 2

[0047] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 As shown, further, in order to better realize the present invention, the control console is provided with a guide rail 51 for moving the loading and unloading robot 5 , and the guide rail 51 is provided between the numerical control machine tool 4 and the material rack 1 .

[0048]Further, in order to better realize the present invention: the zero point positioning tray 6 is provided with positioning pins on the side close to the zero point positioning base 7, and the side of the zero point positioning base 7 close to the zero point positioning tray 6 is provided with pins for installation Locating holes for locating pins.

[0049] Further, in order to better realize the present invention, the measuring machine 2 is a three-coordinate measuring machine.

[0050] It should be noted that, through the above improvements, preferably, when in use, a plurality of parallel CNC machine...

Embodiment 3

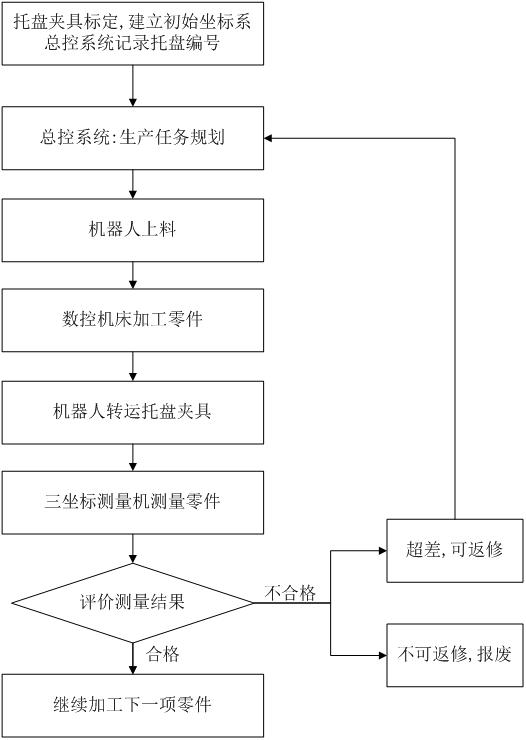

[0056] This embodiment is further optimized on the basis of the above embodiments, such as figure 2 , image 3 As shown, an online detection method for a flexible production line of small workpieces specifically includes the following steps:

[0057] Step S1: establish an initial measurement coordinate system on the zero point positioning pallet 6, mark the measurement system, and install the workpiece on the zero point positioning pallet 6;

[0058] Step S2: Establish a measurement subroutine library, and record the number of the zero point positioning tray 6 on the master console 3;

[0059] Step S3: According to the production task planning, the master console 3 controls the loading and unloading robot 5 to transport the zero-point positioning tray 6 with the specified number of the workpiece to be processed to the specified CNC machine tool 4, and the CNC machine tool 4 performs workpiece processing; The CNC machine tool 4 processes the workpiece, and after the processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com