Preparation method of novel high-strength environment-friendly plate

A high-strength, environmentally friendly technology, applied in the pretreatment of molding materials, flat products, manufacturing tools, etc., can solve the problems of poor wood corrosion and moth resistance, low moisture content inside the board, easy drying and cracking, etc. Insect moth resistance, improvement of strength and anti-corrosion performance, and improvement of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

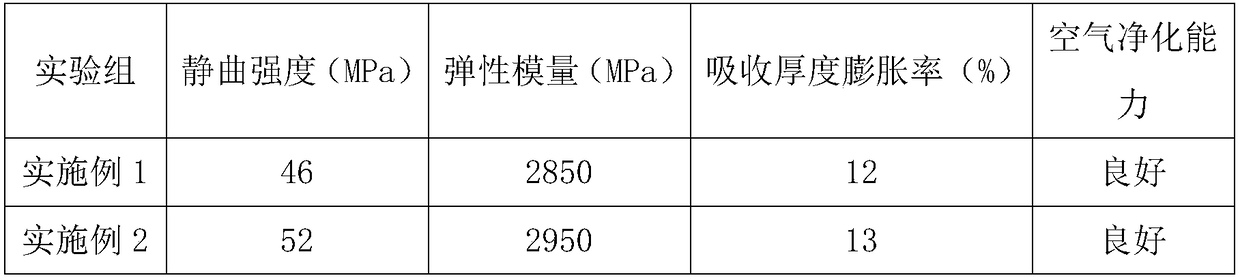

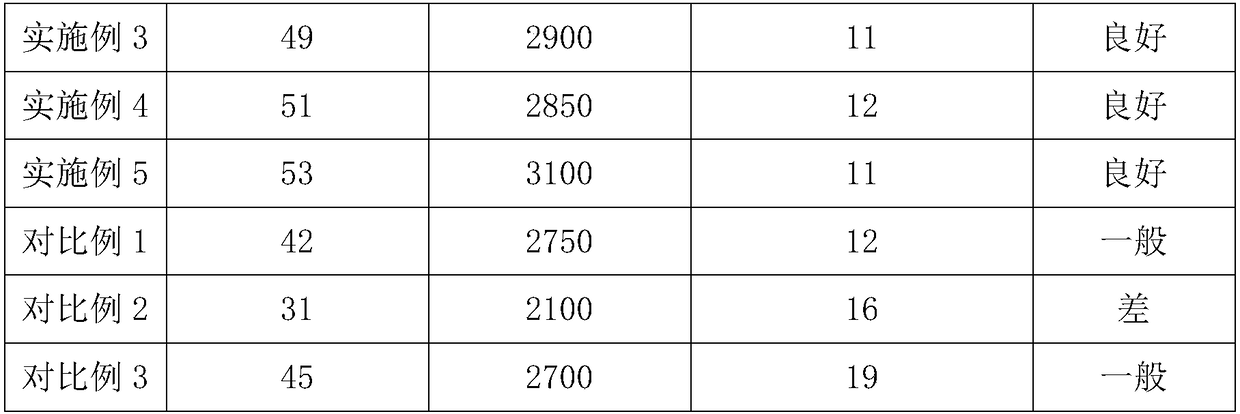

Examples

Embodiment 1

[0038] A method for preparing a novel environment-friendly high-strength environment-friendly plate, comprising the following steps:

[0039] (1) Send the waste wood to a pulverizer to be crushed until the particle size is less than 1 cm, and at the same time crush the Chinese herbal medicine additive to a particle size of less than 1 cm, and mix the Chinese herbal medicine additive and the waste wood material according to the mass ratio of 1:50 to obtain wooden material;

[0040] Chinese herbal supplements include the following ingredients: Gardenia, Mugwort, Pyrethrum, Tangerine Peel, Eucommia, Pepper Root and Peppermint;

[0041] (2) After adding the woody material into the screening machine and vibrating and screening to remove the silt impurities, after adding sodium sulfite equivalent to 3% of its weight and stirring and mixing, add it to the digester for cooking and softening;

[0042] (3) adding the woody material after cooking and softening in the step (2) to a therm...

Embodiment 2

[0062] A method for preparing a novel environment-friendly high-strength environment-friendly plate, comprising the following steps:

[0063] (1) Send the waste wood to a pulverizer to be crushed until the particle size is less than 1 cm, and at the same time, crush the Chinese herbal medicine additive to a particle size of less than 1 cm, and mix the Chinese herbal medicine additive and the waste wood material according to the mass ratio of 3:50 to obtain wooden material;

[0064] Chinese herbal supplements include the following ingredients: Gardenia, Mugwort, Pyrethrum, Tangerine Peel, Eucommia, Pepper Root and Peppermint;

[0065] (2) After adding the woody material to the screening machine and vibrating and screening to remove the silt impurities, after adding sodium sulfite equivalent to 8% of its weight and stirring and mixing, add it to the digester for cooking and softening;

[0066] (3) Add the wood material after cooking and softening in the heat refiner to heat for...

Embodiment 3

[0086] A method for preparing a novel environment-friendly high-strength environment-friendly plate, comprising the following steps:

[0087] (1) Send the waste wood to a pulverizer to be crushed until the particle size is less than 1 cm, and at the same time, crush the Chinese herbal medicine additive to a particle size of less than 1 cm, and mix the Chinese herbal medicine additive and the waste wood material according to the mass ratio of 1.8:50 to obtain wooden material;

[0088] The Chinese herbal medicine additive includes the following raw materials: gardenia, mugwort, pyrethrum, tangerine peel, eucommia, pea root and mint;

[0089] (2) After adding the wood material into the screening machine and vibrating and screening to remove the silt impurities, after adding sodium sulfite equivalent to 5% of its weight and stirring and mixing, add it to the digester for cooking and softening;

[0090] (3) Add the woody material after cooking and softening in the heat refiner to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com