Method for rapidly culturing anaerobic ammoxidized granular sludge

A technology of anaerobic granular sludge and anaerobic ammonium oxidation, applied in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Long doubling time and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

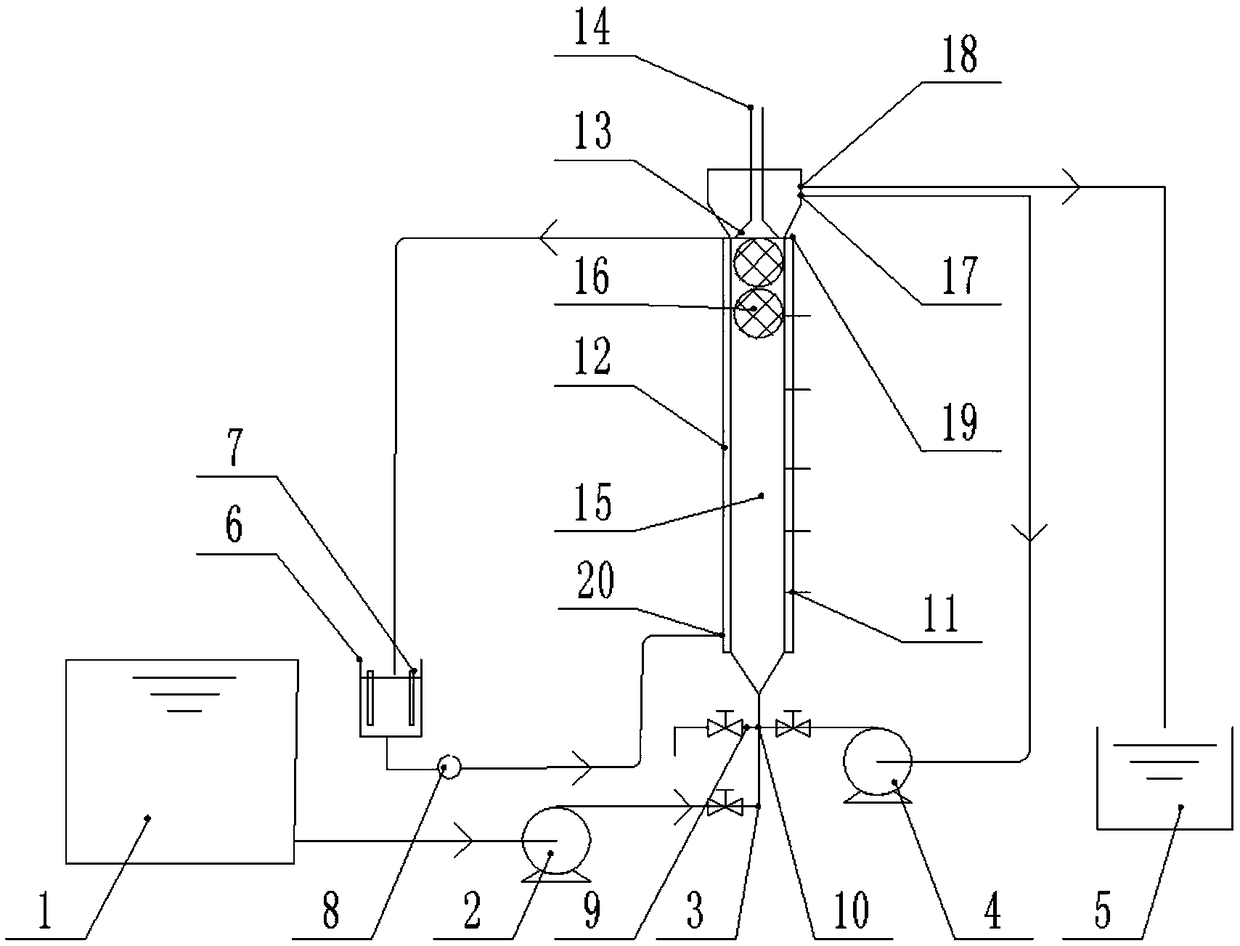

[0031] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0032] see Figure 1-4 , a method for rapid cultivation of anaerobic ammonium oxidation granular sludge, adding 1500ml of anaerobic granular sludge and 500ml of anaerobic ammonium oxidation flocculent sludge into the UASB reactor, and then feeding nitrogen-containing simulated wastewater. This experiment adopts continuous Cultivate, feed water and reflux at the same time, control the temperature of the reactor at 33±2°C by water bath circulation, control the hydraulic retention time at 27h, and control the pH at 7.3-7.6;

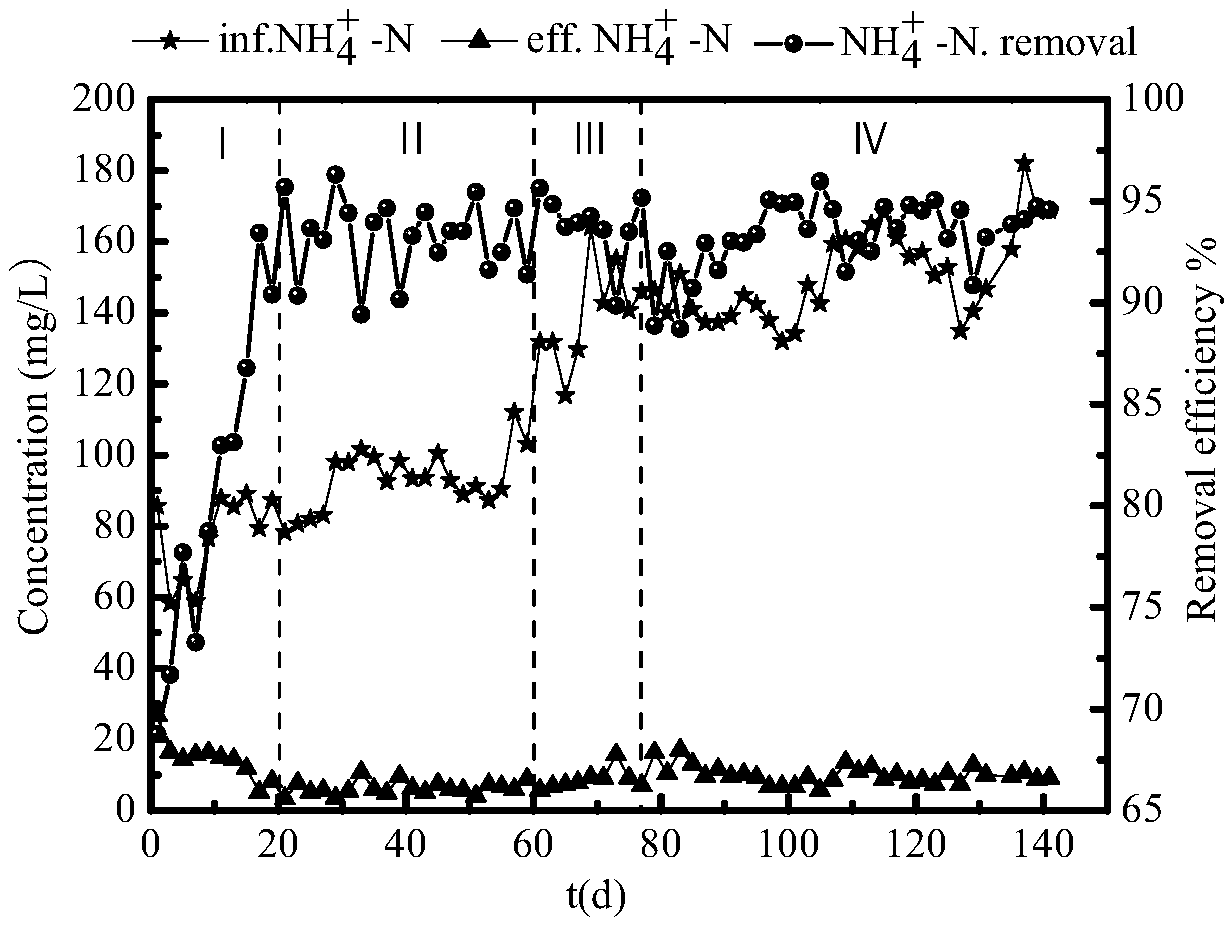

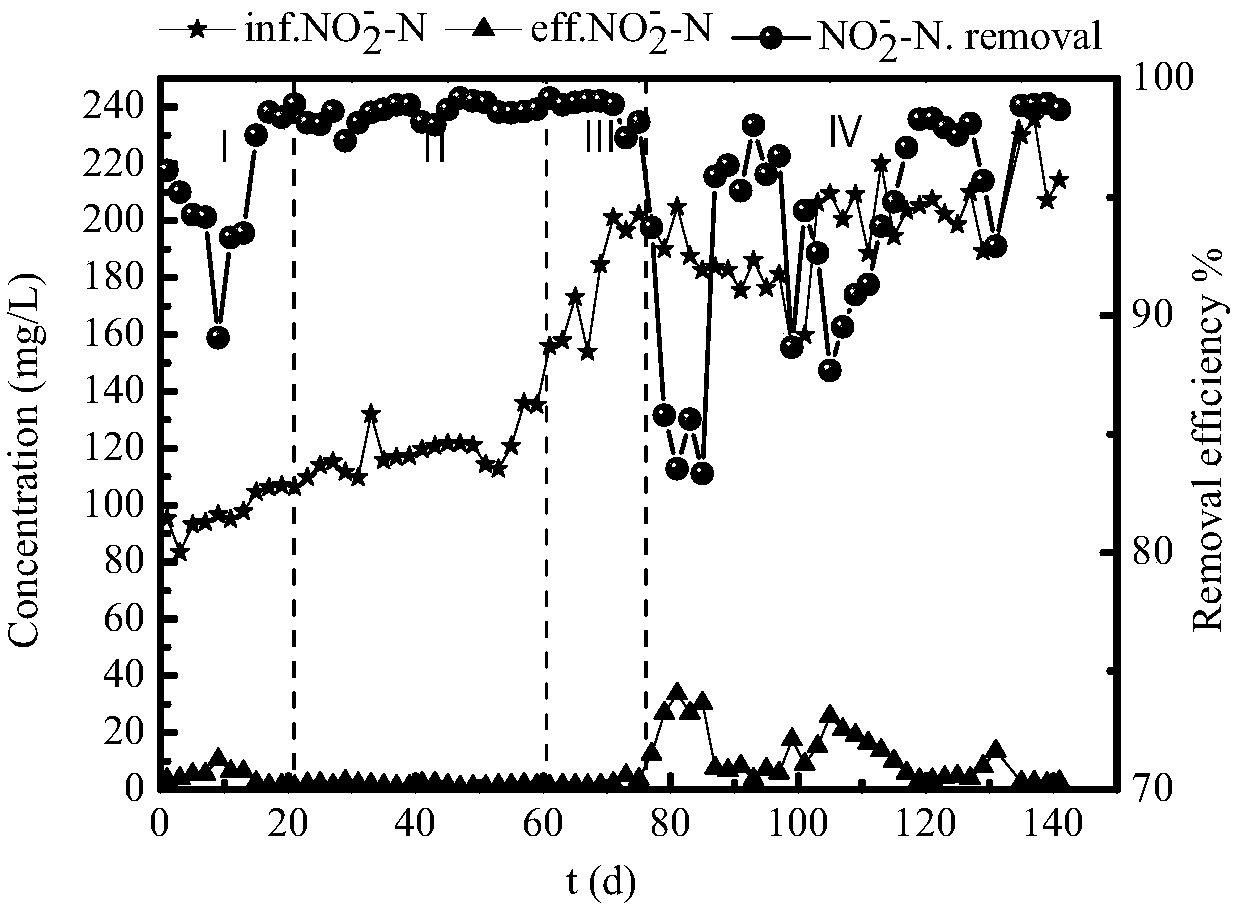

[0033] (1) 1 to 25 days: keep NH in nitrogen-containing simulated wastewater +4 -N concentration is 70±10mg / L, NO -2 - The N concentration is maintained at 80±10mg / L, the reflux ratio is 85%, and the ascending flow rate is 3.3m / h;

[0034] (2) 26-60 days: keep NH in nitrogen-containing simulated wastewater +4 -N concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com