Polymerization method of phthalocyanine

A technology of high molecular weight and phthalocyanine dyes, which is applied in the field of high molecular weight preparation of phthalocyanine dyes, can solve the problems of difficult dispersion, poor adaptability and diversity, and influence on polymerization reactions, etc. Aggregation, improved solubility, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment the present invention is described in further detail.

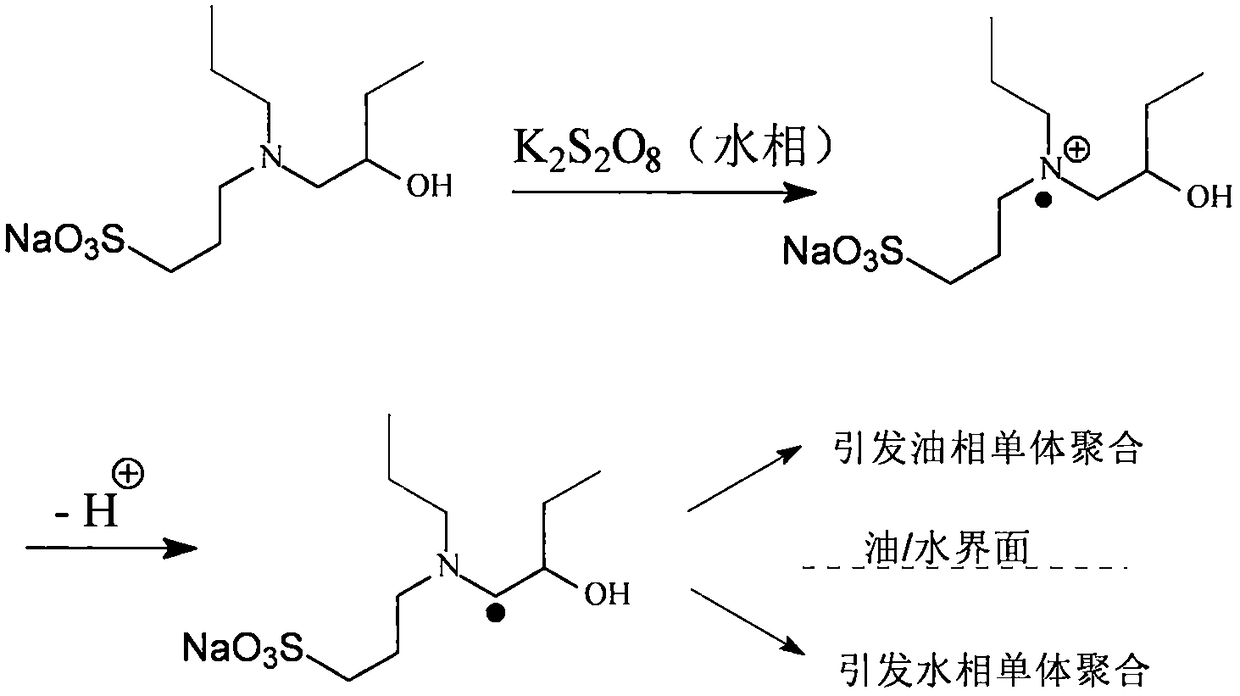

[0021] Preparation of functional initiators:

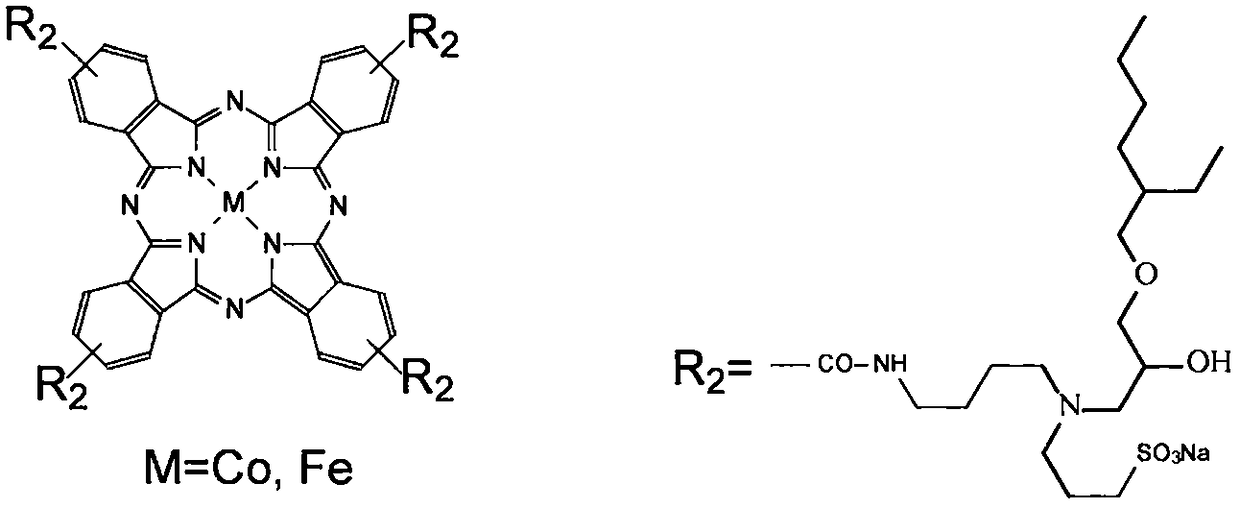

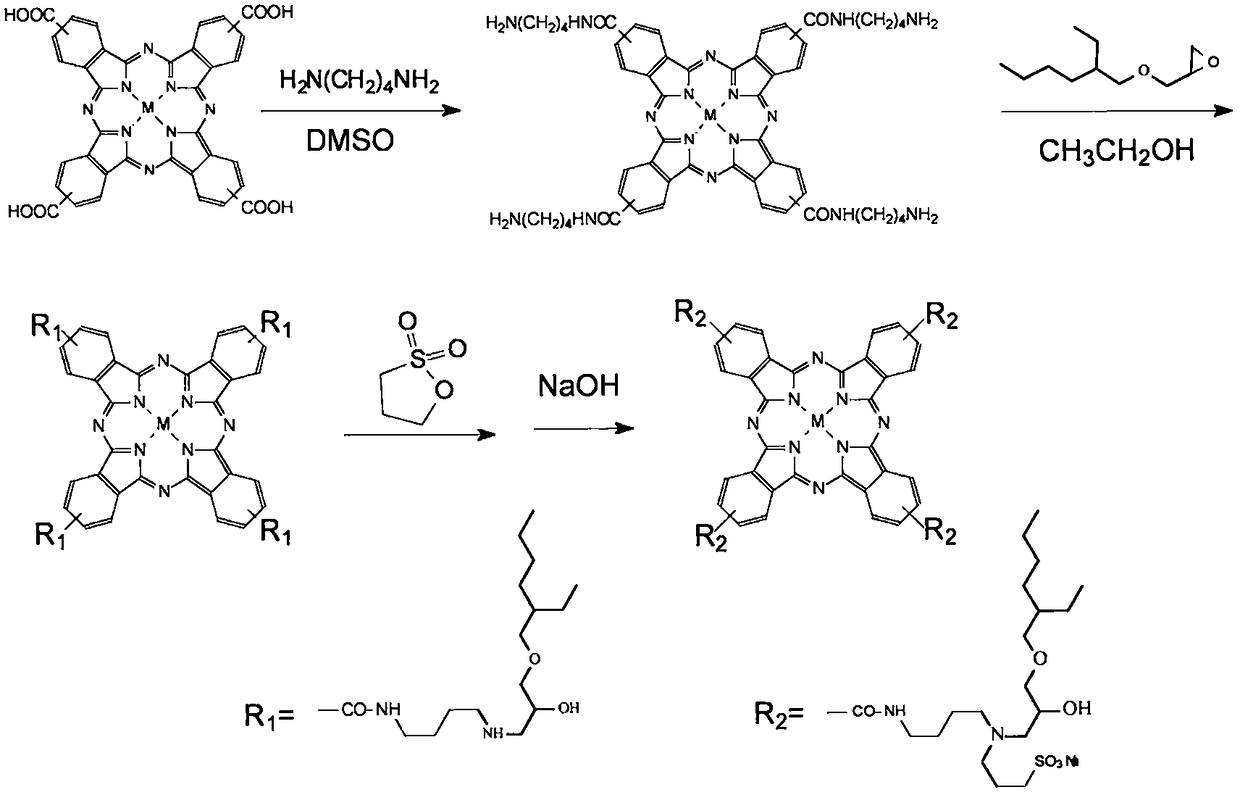

[0022] Tetracarboxyphthalocyanine cobalt and tetracarboxyphthalocyanine iron are used as two starting materials. They have exactly the same method and steps in the process of synthesizing functional initiators, so they are described in a parallel manner. About these two compounds There is a ready-made method for the preparation of , which will not be repeated here. The following are the specific preparation steps:

[0023] 1) Dissolve tetracarboxyl phthalocyanine cobalt (or iron) dye in dimethyl sulfoxide, then add butanediamine, the molar ratio of dye to butanediamine is 1:6, and the weight ratio of dye to dimethylsulfoxide is controlled In the range of 1:4 to 1:5, the temperature of the reaction solution is controlled in the range of 120 to 140°C under stirring, and the reaction time is 3 to 4 hours. Washed several times, filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com