Plastic alloy and method for preparing same

A technology of plastic alloys and metal salts, applied in the field of plastic alloys and their preparation, can solve the problems of low temperature impact resistance, low polycarbonate toughness, and impact properties, etc., and achieve complementary advantages of components and excellent low temperature impact resistance. , the effect of excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

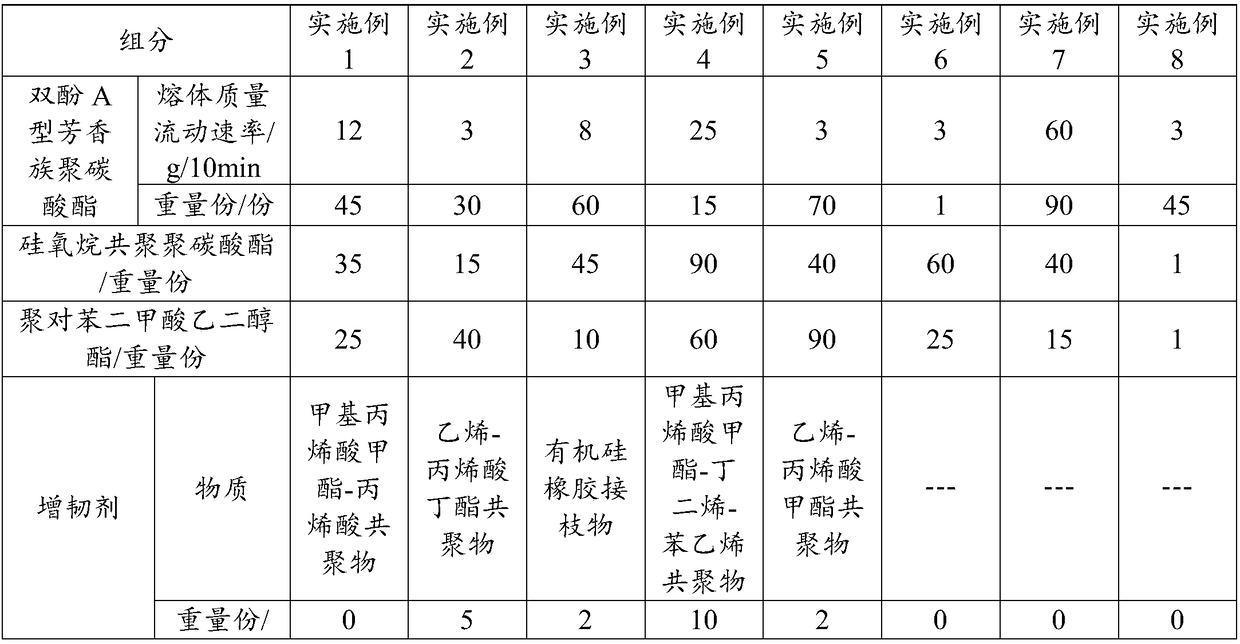

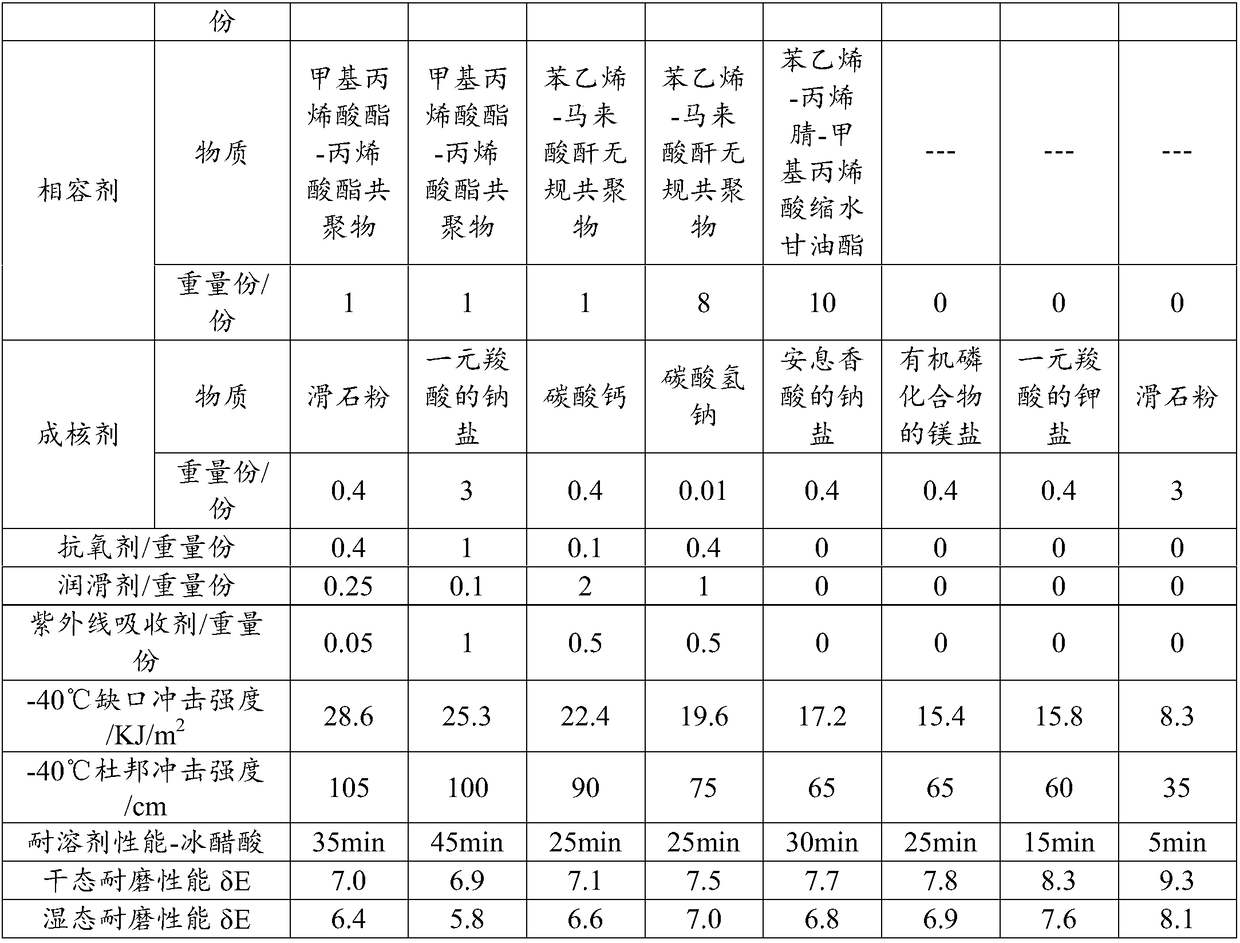

[0028] An embodiment of the plastic alloy of the present invention, the composition of the plastic alloy in this embodiment is shown in Table 1.

[0029] The preparation method of plastic alloy described in the present embodiment is:

[0030] (1) Weigh each component in the plastic alloy in proportion, and put it into a high-mixer, fully mix it evenly, and obtain the mixture;

[0031] (2) Add the mixture obtained in step (1) into a twin-screw extruder to extrude and granulate to obtain the plastic alloy; wherein, the temperature of each zone of the twin-screw extruder is 200-270° C., and the feeding speed is 15 -40kg / h, the rotational speed of the screw is 150-450r / min.

Embodiment 2~8

[0033] The components of the plastic alloys described in Examples 2-8 are all shown in Table 1, and the preparation methods of the plastic alloys described in Examples 2-8 are the same as in Example 1.

[0034] At the same time, the following properties of the plastic alloys described in Examples 1-8 were tested: -40°C notched impact strength, -40°C Dupont impact strength, solvent resistance (glacial acetic acid), dry wear resistance, wet wear resistance. Among them, the test methods for each performance are:

[0035] -40℃ notched impact: reference standard ISO 180;

[0036] -40°C DuPont impact: Cool the 100mm×100mm×2mm square plate in a low-temperature freezer at -40°C for 6 hours, and quickly take it out for low-temperature Dupont impact; the DuPont impact specification weight is 2kg, and the impact cone radius is 1 / 8in;

[0037] Solvent resistance: Fix the ISO tensile spline on a curved surface fixture with a curvature of 1, brush the corresponding solvent in the middle of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com