A reaction control system and method for an externally heated rotary furnace dry distillation device

A technology of external heating rotary furnace and reaction control system, applied in general control system, control/regulation system, indirect heating dry distillation, etc., can solve the problems of increased energy consumption, low coal conversion rate, large temperature fluctuation in the furnace, etc. Achieve the effect of increasing yield and improving coal conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

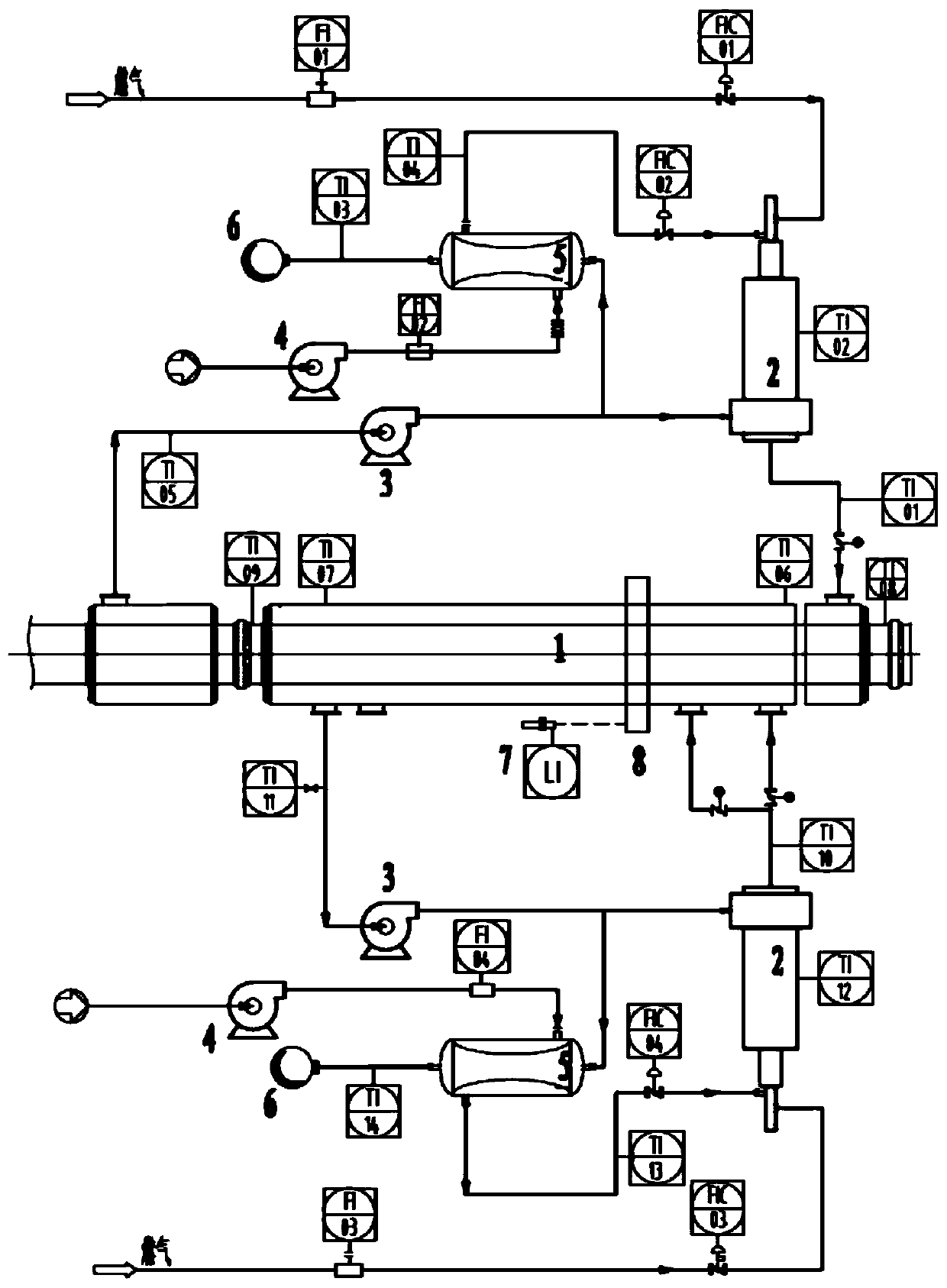

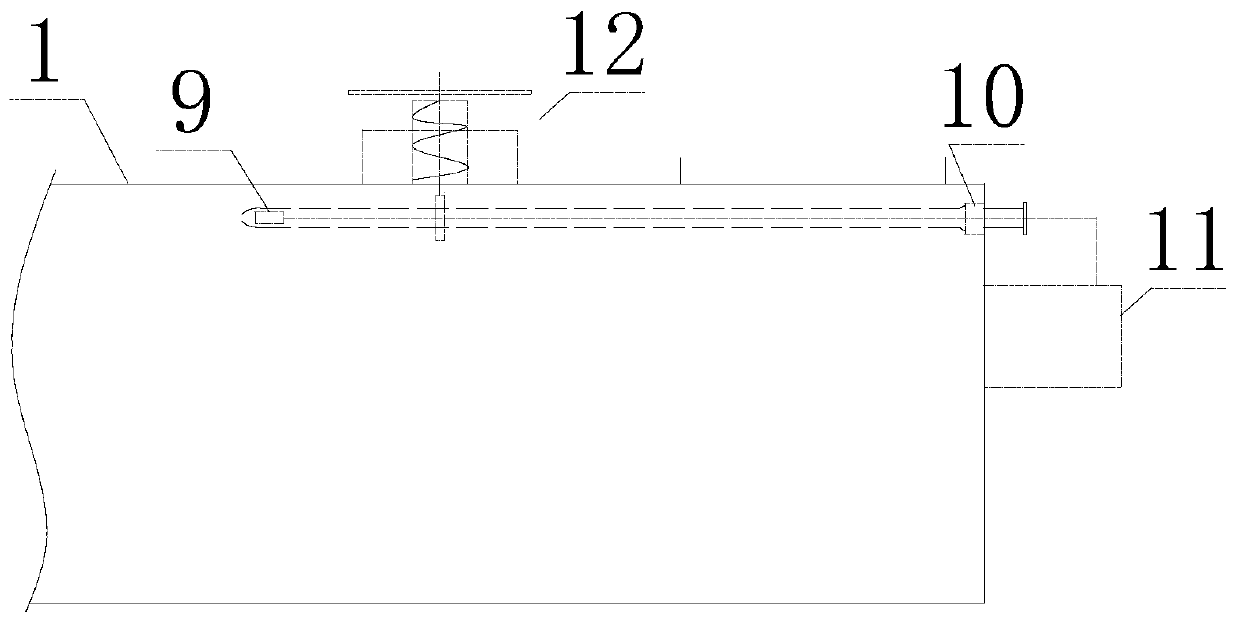

[0042] as attached figure 1 As shown, this embodiment provides a reaction control system for an externally heated rotary furnace retort device, which includes a three-stage outer jacket of the externally heated rotary furnace and a series of tubes inside the cylinder, and the jacket is provided with two Hot air inlet and 1 hot air outlet; the tubes in the cylinder are respectively connected with the hot air inlet and hot air outlet on the outer jacket of the cylinder at both ends, and the hot air inlet and hot air outlet on the outer jacket of the third section of the cylinder are respectively connected with the hot air system. The gas supply pipe is connected to the gas supply system, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com