6XXX-series aluminum alloy and preparation method thereof

A technology of aluminum alloy and intermediate alloy, applied in the field of metal alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

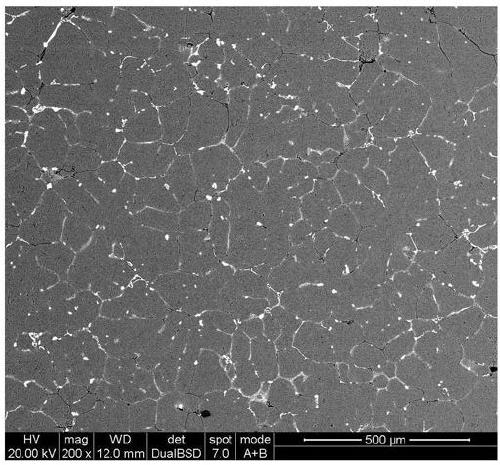

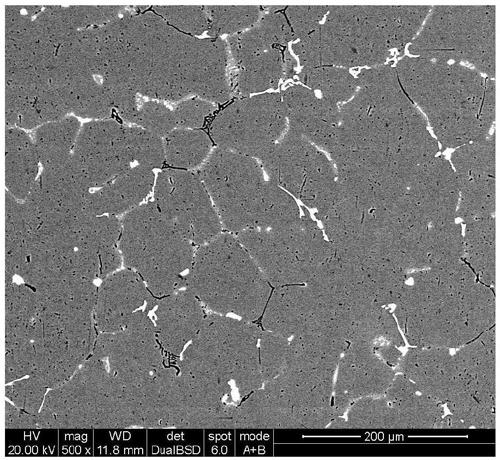

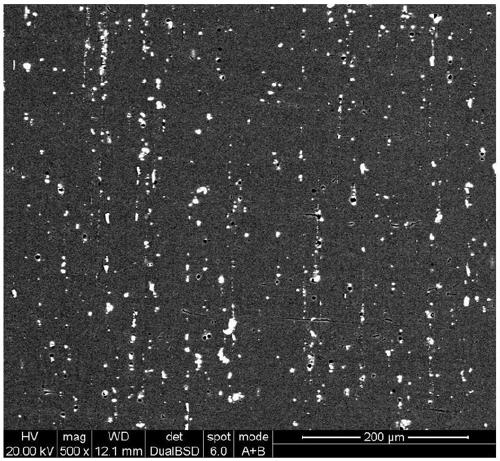

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method for the above-mentioned 6XXX series aluminum alloy, comprising the following steps:

[0038] (1) Weigh pure aluminum ingots, pure magnesium ingots, aluminum-silicon master alloys, aluminum-copper master alloys, aluminum-manganese master alloys, aluminum-chromium master alloys, aluminum-yttrium master alloys, aluminum-zirconium master alloys, and Master alloy, aluminum strontium master alloy;

[0039] (2) smelting the raw materials in the step (1) with a refining agent, a covering agent and a refining agent to obtain an aluminum alloy melting solution;

[0040] (3) Perform casting, annealing, extrusion, solution treatment and aging treatment on the molten aluminum alloy obtained in the step (2) in sequence to obtain the 6XXX series aluminum alloy.

[0041] The present invention weighs pure aluminum ingots, pure magnesium ingots, aluminum-silicon master alloys, aluminum-copper master alloys, aluminum-manganese master...

Embodiment 1

[0056] A 6XXX series aluminum alloy prepared from the following elemental components in weight percent: Mg 0.92%, Si 2.0%, Cu 0.3%, Mn 0.4%, Cr 0.1%, Y 0.25%, Zr 0.15%, Sr 0.10%, Ti 0.02%, Zn 0.1%, Fe 0.2%, single impurity ≤ 0.05%, total impurity ≤ 0.15%, the balance is Al.

[0057] The preparation method comprises the following steps:

[0058] (1) Weigh pure aluminum ingots, pure magnesium ingots, aluminum-silicon master alloys, aluminum-copper master alloys, aluminum-manganese master alloys, aluminum-chromium master alloys, aluminum-yttrium master alloys, and aluminum-zirconium master alloys according to the weight percentages of the above elements , Al-Sr master alloy;

[0059] (2) After melting the pure aluminum ingot at 780°C, add aluminum-silicon master alloy, aluminum-copper master alloy, aluminum-manganese master alloy, aluminum-chromium master alloy, aluminum-yttrium master alloy, aluminum-zirconium master alloy, aluminum-strontium master alloy, covering agent and r...

Embodiment 2

[0067] A 6XXX series aluminum alloy prepared from the following elemental components in weight percent: Mg 0.90%, Si 2.2%, Cu 0.3%, Mn 0.4%, Cr 0.12%, Y 0.27%, Zr 0.15%, Sr 0.10%, Ti 0.03%, Zn 0.09%, Fe 0.17%, single impurity ≤ 0.05%, total impurity ≤ 0.15%, the balance is Al.

[0068] The preparation method comprises the following steps:

[0069] (1) Weigh pure aluminum ingots, pure magnesium ingots, aluminum-silicon master alloys, aluminum-copper master alloys, aluminum-manganese master alloys, aluminum-chromium master alloys, aluminum-yttrium master alloys, and aluminum-zirconium master alloys according to the weight percentages of the above elements , Al-Sr master alloy;

[0070] (2) After melting the pure aluminum ingot at 780°C, add aluminum-silicon master alloy, aluminum-copper master alloy, aluminum-manganese master alloy, aluminum-chromium master alloy, aluminum-yttrium master alloy, aluminum-zirconium master alloy, aluminum-strontium master alloy, covering agent an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com