A kind of al-zn-mg-cu ultrahigh-strength aluminum alloy and its rapid extrusion on-line quenching production method

A production method and technology for aluminum alloy, applied in the field of aluminum alloy materials, can solve the problems of over-burning solid solution quenching, low quenching sensitivity, low production efficiency, etc. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

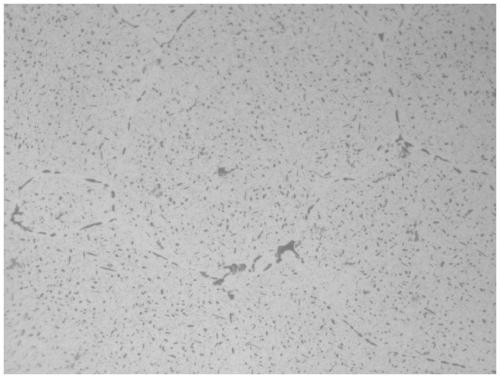

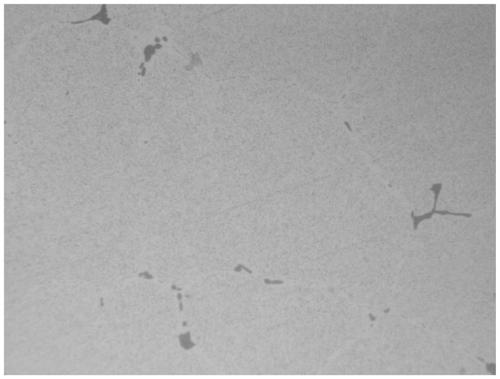

Image

Examples

Embodiment 1

[0029]An Al-Zn-Mg-Cu ultra-high-strength aluminum alloy, the composition and mass percentage of the aluminum alloy are as follows: Zn: 6.2%, Mg: 2.0%, Cu: 0.4%, Si: 0.25%, Mn: 0.12%, Cr: 0.04%, Ti: 0.04%, Zr: 0.02%, Fe: 0.08%, Al: balance.

[0030] The rapid extrusion on-line quenching production method of the Al-Zn-Mg-Cu ultra-high-strength aluminum alloy comprises the following steps:

[0031] S1, batching; S2, smelting; S3, casting; S4, ingot homogenization; S5, ingot wagon, sawing; S6, ingot heating; S7, mold heating; S8, extrusion barrel heating; S9, extrusion ; S10, online quenching; S11, stretching and straightening; S12, aging.

[0032] In step S4, the homogenization of the ingot adopts a three-stage homogenization process, the first stage is heating to 410°C for 8 hours, the second stage is heating to 470°C for 20 hours, and the third stage is cooling to 360°C and holding for 5 hours , and finally cooled to below 250°C at a rate not greater than 30°C / h.

[0033] In...

Embodiment 2

[0040] An Al-Zn-Mg-Cu ultra-high-strength aluminum alloy, the alloy composition and mass percentage are as follows: Zn: 5.5%, Mg: 1.8%, Cu: 0.30%, Si: 0.20%, Mn: 0.10%, Cr: 0.02 %, Ti: 0.03%, Zr: 0.02%, Fe: 0.10%, Al: balance.

[0041] The rapid extrusion on-line quenching production method of the Al-Zn-Mg-Cu ultra-high-strength aluminum alloy comprises the following steps:

[0042] S1, batching; S2, smelting; S3, casting; S4, ingot homogenization; S5, ingot wagon, sawing; S6, ingot heating; S7, mold heating; S8, extrusion cylinder heating; S9, extrusion ; S10, online quenching; S11, stretching and straightening; S12, aging.

[0043] In step S4, the homogenization of the ingot adopts a three-stage homogenization process, the first stage is heating to 400°C for 20 hours; the second stage is heating to 465°C for 30 hours; the third stage is cooling to 340°C and holding for 15 hours ;Finally cool to below 250°C at a rate not greater than 30°C / h.

[0044] In step S6, the ingot ...

Embodiment 3

[0051] An Al-Zn-Mg-Cu ultra-high-strength aluminum alloy, the alloy components and mass percentages are as follows:

[0052] Zn: 6.5%, Mg: 2.2%, Cu: 0.60%, Si: 0.30%, Mn: 0.15%, Cr: 0.06%, Ti: 0.05%, Zr: 0.03%, Fe: 0.11%, Al: balance.

[0053] The rapid extrusion on-line quenching production method of the Al-Zn-Mg-Cu ultra-high-strength aluminum alloy comprises the following steps:

[0054] S1, batching; S2, smelting; S3, casting; S4, ingot homogenization; S5, ingot wagon, sawing; S6, ingot heating; S7, mold heating; S8, extrusion barrel heating; S9, extrusion ; S10, online quenching; S11, stretching and straightening; S12, aging.

[0055] In step S4, the homogenization of the ingot adopts a three-stage homogenization process, the first stage is heating to 430°C for 2 hours; the second stage is heating to 475°C for 10 hours; the third stage is cooling to 370°C and holding for 3 hours ;Finally cool to below 250°C at a rate not greater than 30°C / h.

[0056] In step S6, the he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com