Aluminum alloy laser preprocessing and anti-corrosion reinforcing process

A laser pretreatment, aluminum alloy technology, applied in the field of laser applications, to achieve the effect of improved test strength, good processing quality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

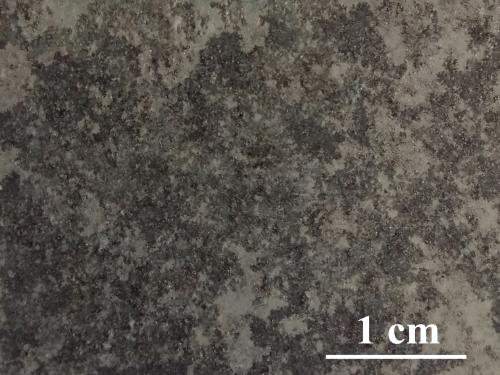

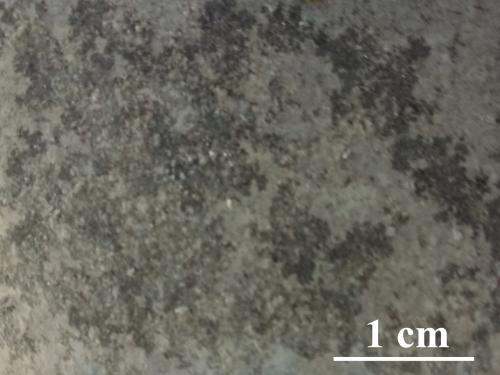

Image

Examples

Embodiment 1

[0030] The 7xxx series alloy is Al-6Zn-2.9Mg-1.6Cu and polished to a metallic luster with 2000 sandpaper; the box-type resistance furnace is heated to 470˚C, and the alloy is put into the furnace after the temperature is stable, and the aluminum alloy is solid-soluted Treatment, solid solution treatment time 1h; during the solid solution process, the aluminum alloy is protected by argon gas. The aluminum alloy after solid solution treatment is quickly taken out of the box-type resistance furnace and placed on the laser workbench. The laser used in the laser workbench is a semiconductor laser. The workbench drives the aluminum alloy to sweep the laser spot across the surface of the alloy. The parameters are: 1100, 2mm / s, the defocus of the laser on the workpiece surface is 35mm, and the aluminum alloy is protected by argon gas during the laser processing. After the laser scans the alloy, it is quickly taken out and quenched; quenching uses deionized water at a temperature of 0-...

Embodiment 2

[0036]The 7xxx series alloy is Al-6Zn-2.9Mg-1.6Cu and polished to a metallic luster with 2000 sandpaper; the box-type resistance furnace is heated to 450˚C, and the alloy is put into the furnace after the temperature is stable, and the aluminum alloy is solid-soluted The solid solution treatment time is 6h; the aluminum alloy is protected by argon gas during the solid solution process. The aluminum alloy after solid solution treatment is quickly taken out of the box-type resistance furnace and placed on the laser workbench. The laser used in the laser workbench is a semiconductor laser. The workbench drives the aluminum alloy to sweep the laser spot across the surface of the alloy. The parameters are: 1350W, 1mm / s, the defocus of the laser on the workpiece surface is 30mm, and the aluminum alloy is protected by argon gas during the laser processing. After the laser scans the alloy, it is quickly taken out and quenched; quenching uses deionized water at a temperature of 0-5˚C, ...

Embodiment 3

[0039] The 7xxx alloy is Al-6Zn-2.9Mg-1.6Cu and polished to a metallic luster with No. 2000 sandpaper; the box-type resistance furnace is equipped with a heat preservation container, which is a square container made of aluminum silicate fiberboard, and the top of the container is not silicon Acid aluminum fiberboard is ultra-clear glass with a light transmittance greater than 93%. Put the container in a box-type resistance furnace and heat it up to 470˚C with the furnace. After the temperature in the container is consistent with the furnace temperature, put the aluminum alloy into the box In the heat preservation container in the resistance furnace, solid solution treatment is carried out, and the solid solution treatment time is 1 hour; the aluminum alloy is protected by argon gas during the solid solution process. Take the heat preservation container containing aluminum alloy out of the box-type resistance furnace after solid solution treatment, and place it on the laser work...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com