Anode dyeing process capable of fading colors without loss

A color, anode technology, applied in anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of oxide film corrosion damage, difficulty and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

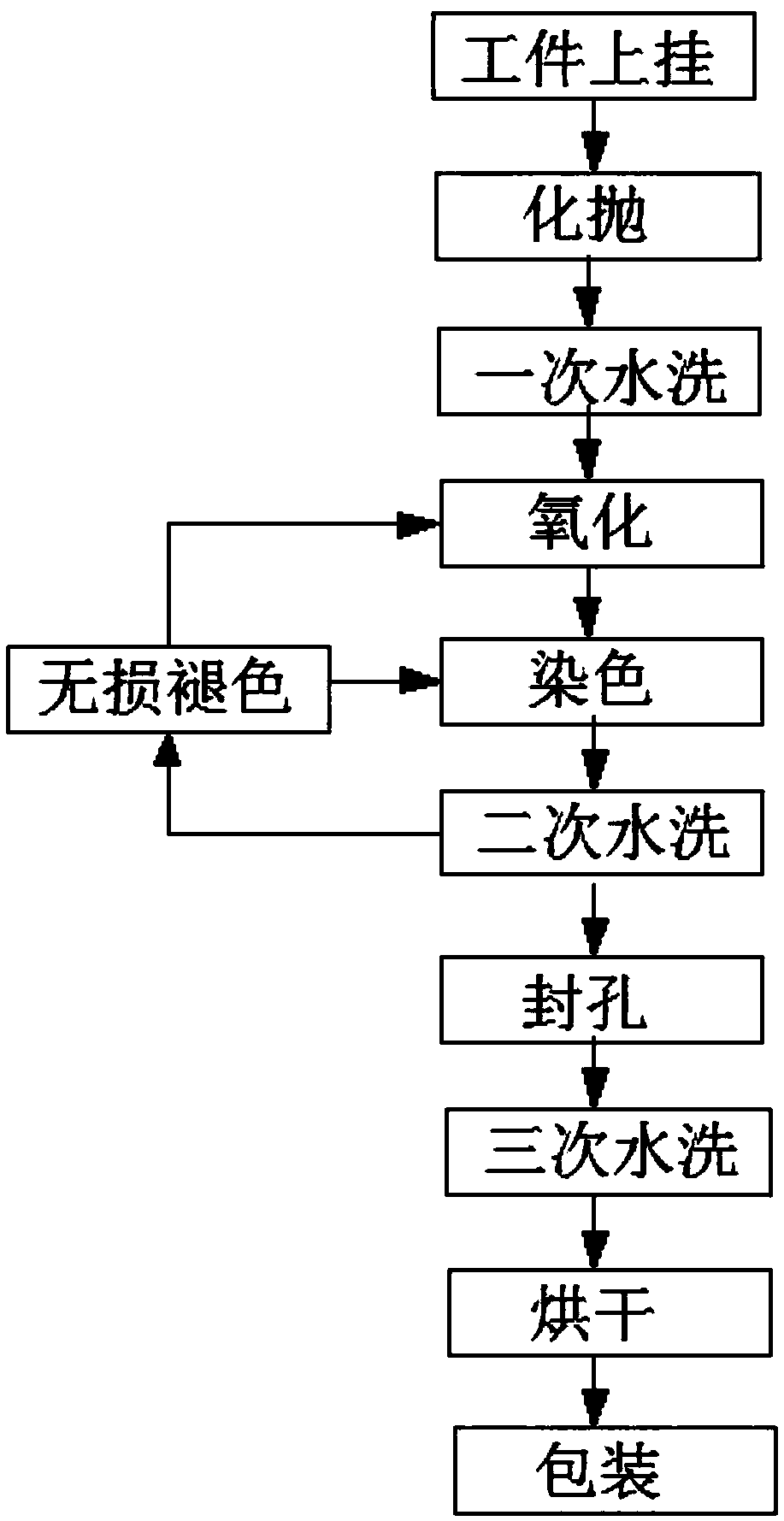

[0023] Please refer to figure 1 As shown, it shows the process flow of the preferred embodiment of the present invention, which is an anodic dyeing process that can remove the color without damage, including hanging the workpiece, chemical polishing, primary washing, oxidation, dyeing, secondary washing, Colorimetry and thickness measurement, non-destructive fading, sealing, three washings, drying, packaging and other steps.

[0024] The specific process of each step is as follows:

[0025] S1, Hanging the workpiece: refers to placing the workpiece to be dyed in the jig, and hanging the jig on the hanging machine that can move back and forth. The workpiece placement adopts the automatic feeding mode, which reduces manual participation, saves labor costs, and improves efficiency. The hanging machine is controlled by PLC program, which makes the moving process of the workpiece fully automatic.

[0026] S2, chemical polishing: refers to the movement of the hanger to make the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com