Quantum dot electroluminescent device and preparation method thereof

An electroluminescent device and quantum dot light-emitting technology, which is applied in the field of quantum dots, can solve problems such as difficult implementation of the method, and achieve the effects of solving difficult implementation, slowing down transmission, and low manufacturing process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

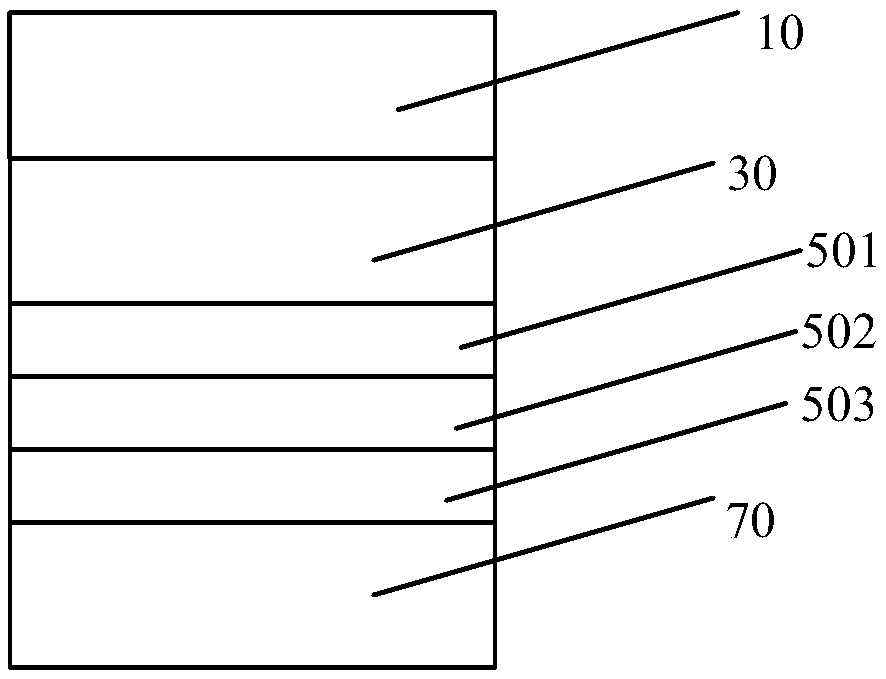

[0044] According to another aspect of the present application, a method for preparing a quantum dot electroluminescent device is also provided, the method comprising the steps of:

[0045] S1, disposing the first electrode layer 10 on the substrate;

[0046] S2, disposing a quantum dot light-emitting layer 30 on the surface of the first electrode layer 10;

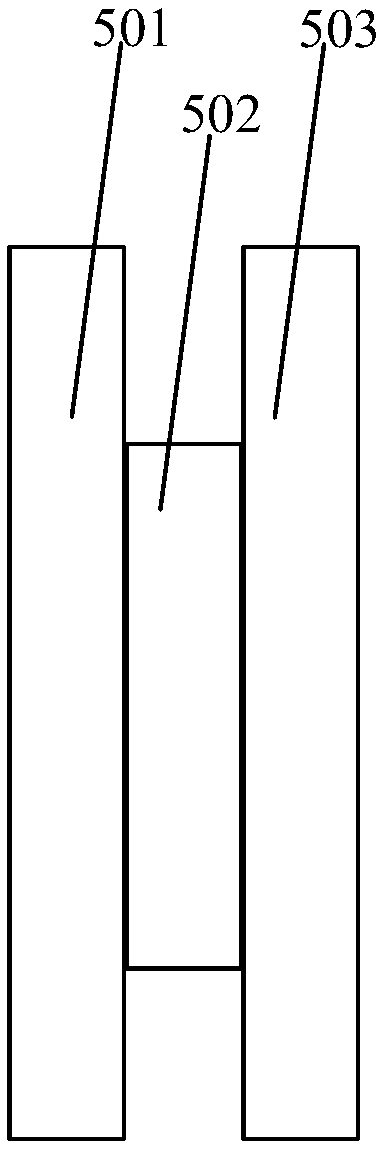

[0047] S3, disposing the functional layer 50 on the surface of the quantum dot light-emitting layer 30 away from the first electrode layer 10, wherein the process of disposing the functional layer 50 includes sequentially laminating and disposing the first A subfunctional layer 501, a second subfunctional layer 502 and a third subfunctional layer 503, wherein the second subfunctional layer 502 includes an electron transport material, and the first subfunctional layer 501 and the third subfunctional layer 503 have corresponding materials The gap widths are respectively greater than the bandgap widths of the electron transp...

Embodiment 1

[0051] The quantum dot electroluminescent device in this embodiment comprises in turn:

[0052] The first electrode layer (ITO cathode, thickness is about 200nm),

[0053] Hole injection layer (PEDOT:PSS, thickness about 40nm),

[0054] A hole transport layer (TFB, about 25nm thick),

[0055] Quantum dot luminescent layer 30 (thickness is about 10nm) formed by red quantum dots,

[0056] The first sub-functional layer 501 (ZrO 2 , the LUMO energy level is about -3.41eV, the HOMO energy level is about -8.41eV, the bandgap width is 4eV, and the thickness is about 20nm), where LUMO is the lowest unoccupied molecular orbital, which is the abbreviation of Lowest Unoccupied Molecular Orbital; HOMO is the highest occupied Molecular Orbital is the abbreviation of Highest Occupied Molecular Orbital.

[0057] The second sub-functional layer 502 (ZnO, the LUMO energy level is about -4.19eV, the HOMO energy level is about -7.39eV, the bandgap width is 3.2eV, and the thickness is about ...

Embodiment 2

[0061] The quantum dot electroluminescent device in this embodiment differs from Embodiment 1 in that:

[0062] Include the first electrode layer (ITO cathode, thickness 200nm) in sequence,

[0063] Hole injection layer (PEDOT:PSS, thickness about 40nm),

[0064] A hole transport layer (TFB, about 25nm thick),

[0065] Quantum dot luminescent layer 30 (thickness 30nm) formed by red quantum dots,

[0066] The first sub-functional layer 501 (NiO, the LUMO energy level is about -4eV, the HOMO energy level is about -7.5eV, the bandgap width is 3.5eV, and the thickness is about 1nm),

[0067] The second sub-functional layer 502 (ZnO, the LUMO energy level is about -4.19eV, the HOMO energy level is about -7.39eV, the bandgap width is 3.2eV, and the thickness is about 20nm),

[0068] The third sub-functional layer (NiO, the LUMO energy level is about -4eV, the HOMO energy level is about -7.5eV, the bandgap width is 3.5eV, and the thickness is about 1nm),

[0069] The second elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com