Heat dissipation device for control heat dissipation assembly and washing machin

A technology of heat dissipation device and heat dissipation plate, which is applied to electrical components, structural parts of electrical equipment, cooling/ventilation/heating renovation, etc. The effect of running noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

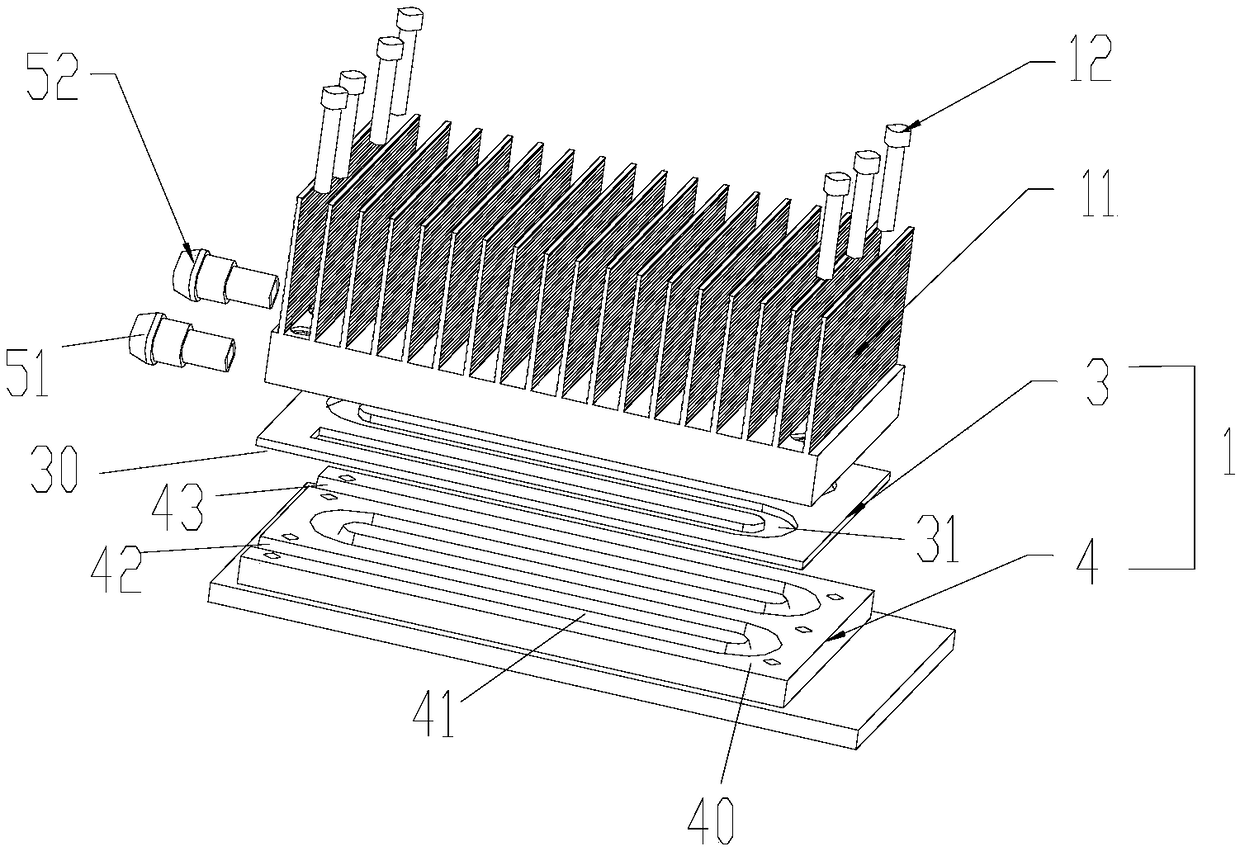

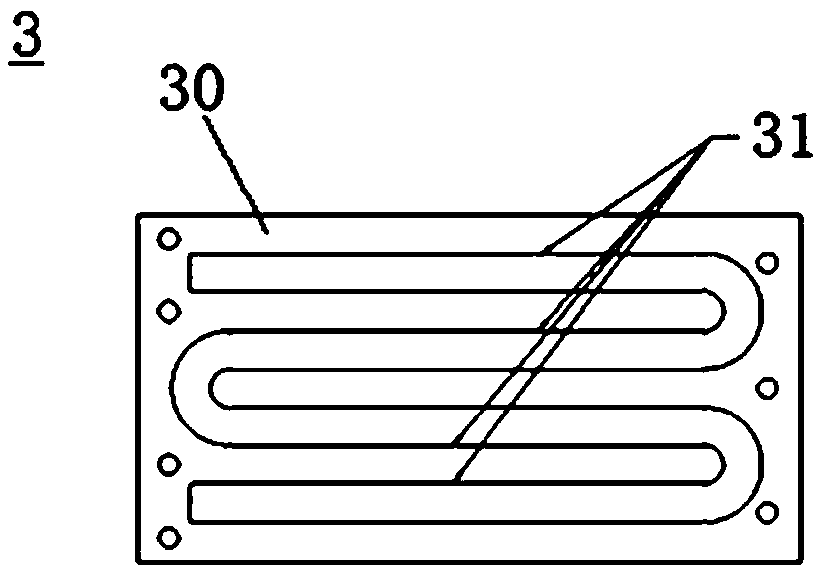

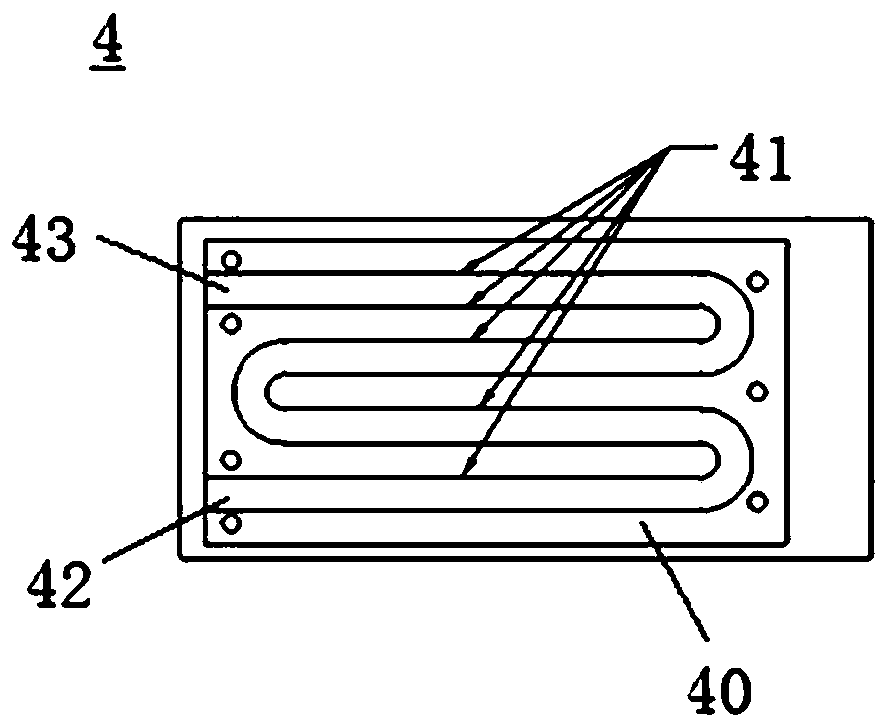

[0033] Such as Figure 1-4 As shown, the present invention provides a heat dissipation device, which includes:

[0034] The water-cooled radiator 1 can receive the condensed water produced by the air conditioner evaporator, and cool and dissipate heat with the electrical box 2 through the flow of the condensed water.

[0035] The present invention sets the water-cooled radiator so that it can receive the condensed water produced by the air conditioner evaporator, and cools and dissipates the controller through the flow of the condensed water, which can effectively replace the existing cooling fan for the controller. The way of heat dissipation, the efficiency of heat dissipation and cooling is high, which can effectively overcome the defect that the radiator has a high temperature during high-frequency operation and cause the heat dissipation effect to deteriorate, and effectively reduce the temperature of the radiator on the control board when the compressor is operating at h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com