Cylinder liner with chamfer and Anti-polishing cuff

A technology of cylinder liner and sleeve, applied in the direction of cylinder, cylinder head, machine/engine, etc., can solve problems such as increasing lubricating oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

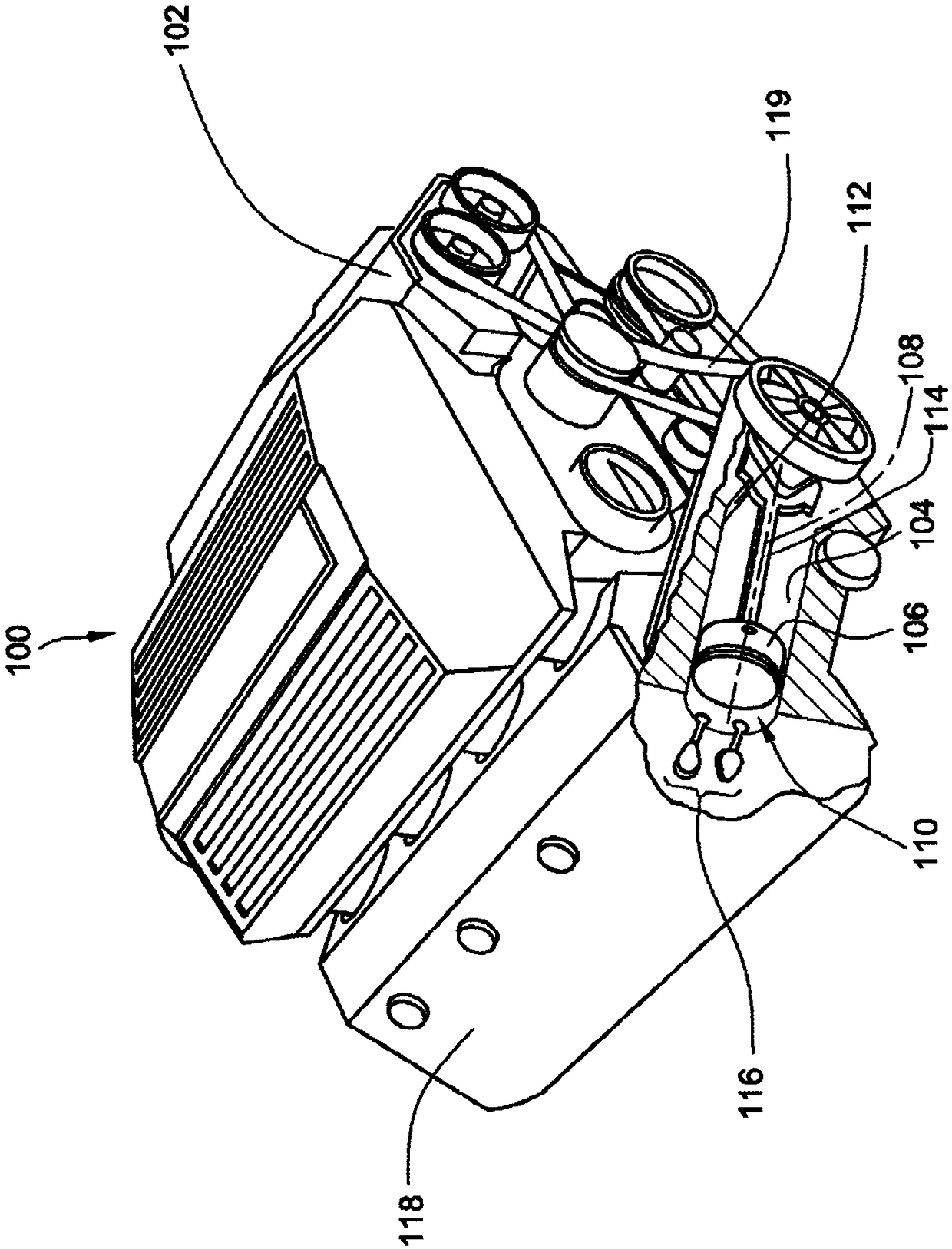

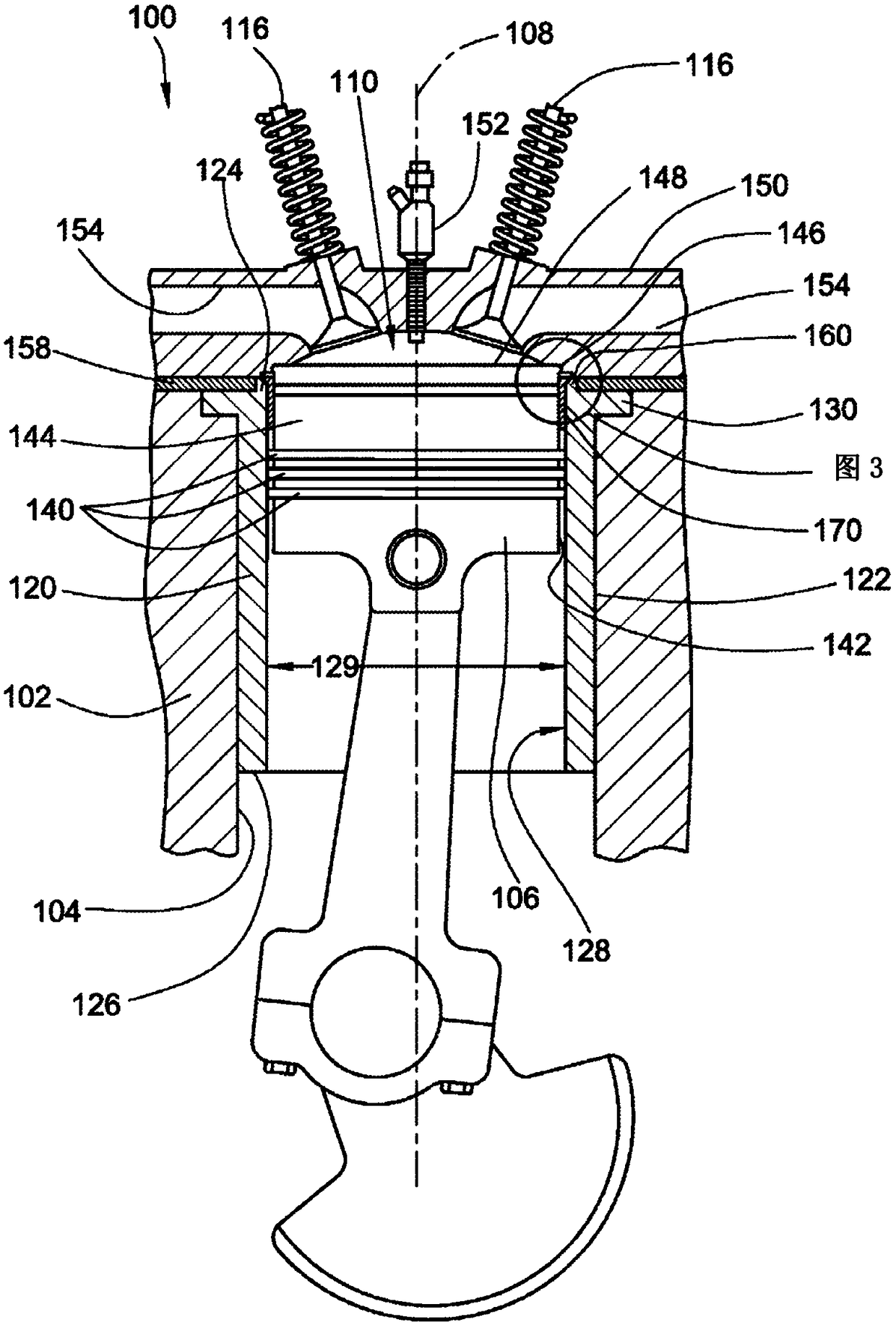

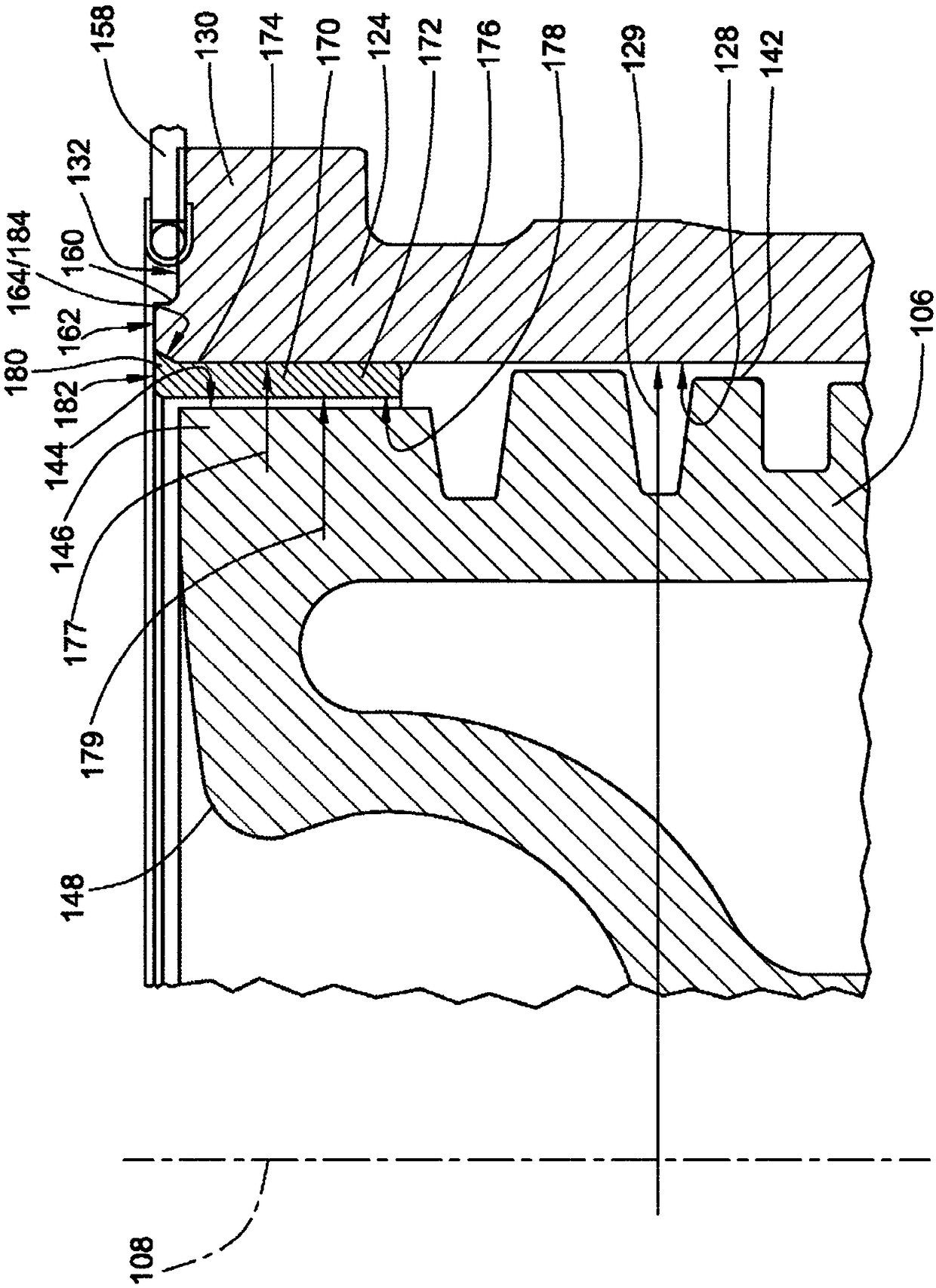

[0010] Referring now to the drawings, in which like reference numerals indicate like elements, in figure 1 An internal combustion engine 100, such as a diesel combustion compression ignition engine or a gasoline combustion spark ignition engine, is shown for converting hydrocarbon-based fuel into mechanical power for powering a machine. As used herein, the term "machine" may refer to any machine that performs some type of operation associated with an industry such as mining, construction, agriculture, transportation, or any other industry known in the art. For example, the machine may be an earth moving machine such as a wheel loader, excavator, dump truck, backhoe, motor grader, material handler, etc. In other embodiments, the machine may be a stationary machine, such as a pump or compressor for inducing fluid flow, or a generator for generating off-grid electricity. Also, the tool can be connected to the machine. Such tools are used for a variety of tasks including, for ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com